Advantages of Robotic Welding – Transforming Industrial Efficiency & Quality

In the dynamic landscape of modern manufacturing, the demand for robotic welding solutions is surging. The metal industry alone is witnessing a consistent increase. As companies globally strive to stay competitive, the shift towards robotic systems is becoming an essential strategy. This aids in maintaining an edge in quality, cost-efficiency, and production speed. At Automated Solutions Australia (ASA) we have over 20 years of expertise in FANUC robot programming and integration to deliver superior welding solutions.

Advantages of Robotic Welding Uncovered

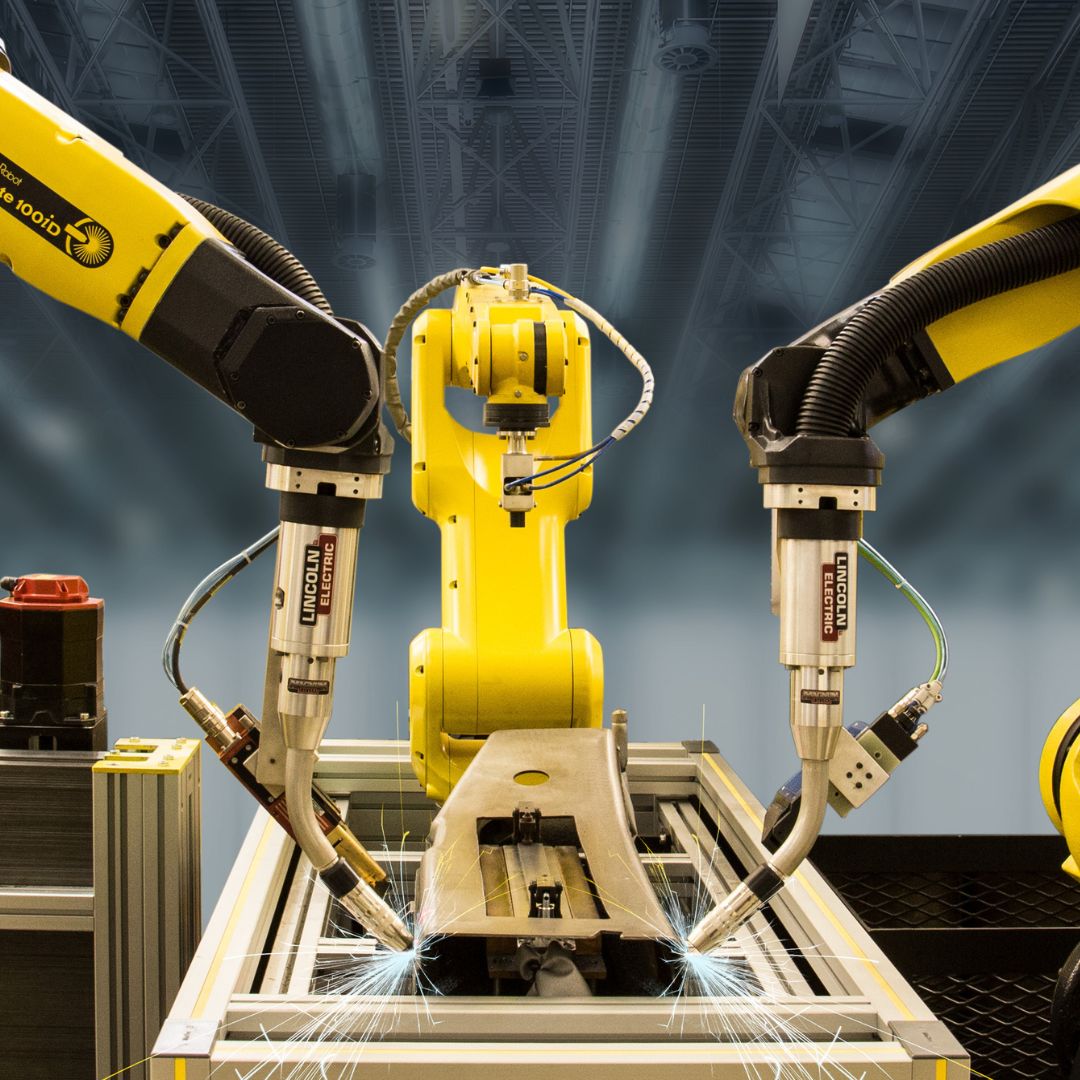

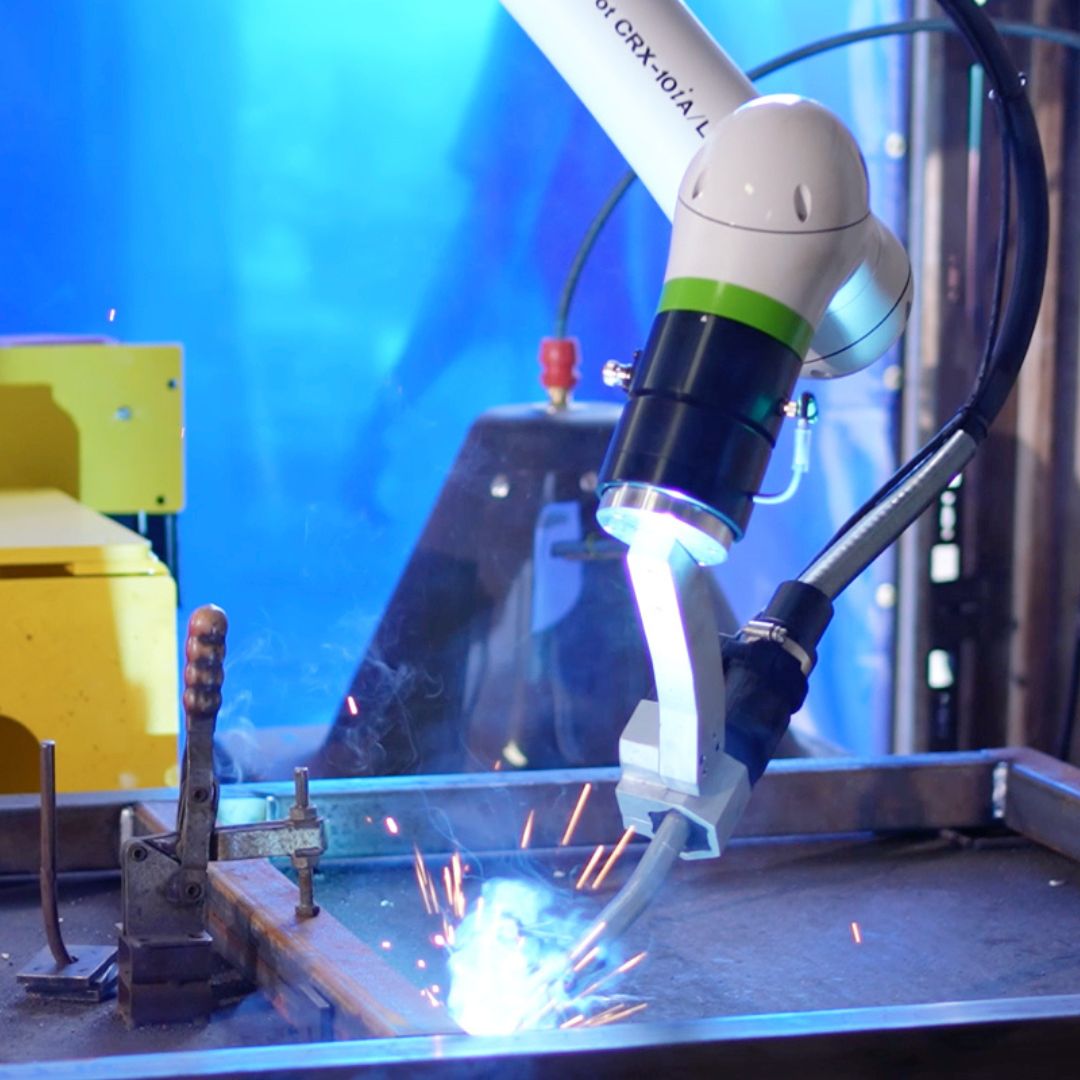

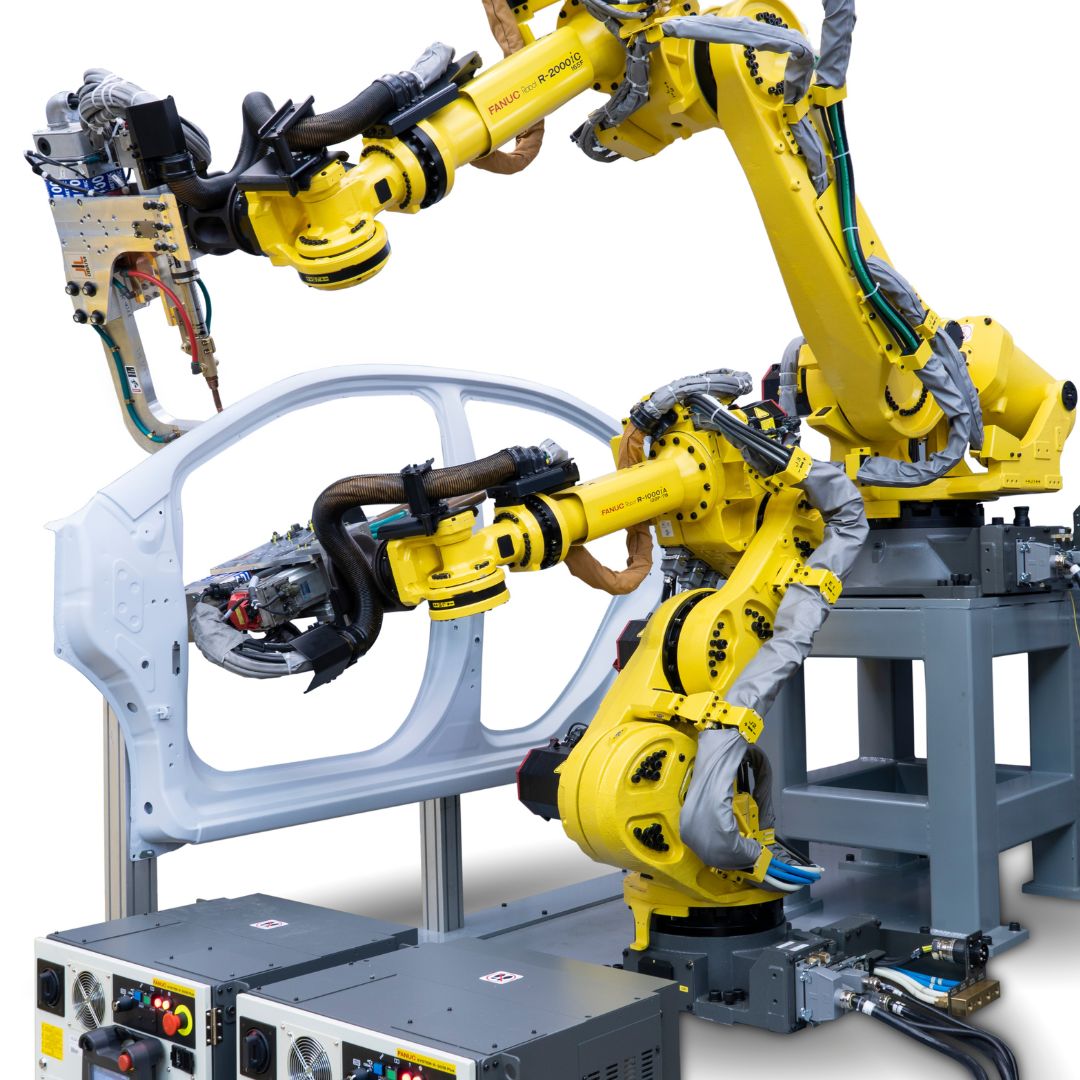

Consistency and Precision: Unlike manual welding, which can suffer from error and inconsistencies, there are a number of advantages of robotic welding. These include unmatched precision. This precision is crucial in industries like automotive assembly and aerospace manufacturing, where even slight discrepancies can be costly. Robotic systems minimise the number of weld passes needed. Therefore reducing the heat distortion typically seen in manual welding and ensuring each product meets high-quality standards.

Efficiency and Production Speed: Robotic welders operate continuously without breaks. Therefore this significantly enhanches production capacity. These systems can function around the clock, drastically reducing cycle times and meeting tight production deadlines. With their ability to perform tasks with high accuracy and minimal downtime, robotic welders are key to increasing productivity.

Safety and Reduced Labor Costs: Robotic welding minimises human exposure to dangerous tasks. Therefore reducing the risk of injuries in the workplace. By automating the welding process, companies can also decrease the number of skilled welders needed on the floor. This thereby addresses skill shortages within the welding industry. We have had clients in remote areas come to us for welding solutions, for this alone.

Material and Cost Efficiency: Robotic welding systems streamline the use of materials by reducing waste and improving the consistency of material usage. This control over material use, combined with reduced operational costs and minimal human intervention, leads to significant long-term savings.

Advantages of Robotic Welding & The Role of ASA

At Automated Solutions Australia, we understand the advantages of robotic welding and that integrating such systems into existing production lines can be daunting. That’s why we offer end-to-end solutions, from system design and customisation to installation and maintenance. Our approach ensures that each system is tailored to meet the specific needs of our clients. Therefore maximising their investment and enhancing their manufacturing capabilities.

Advantages of Robotic Welding | Training and Support

Recognising the complexity of welding systems, ASA provides comprehensive training and support to ensure that your staff can operate your systems effectively. We help bridge the skills gap by making complex systems approachable for your existing workforce, enhancing their capabilities and confidence in managing advanced robotic equipment.

Advantages of Robotic Welding – Looking to the Future

As the manufacturing sector continues to evolve, the advantages of robotic welding are set to play a crucial role in shaping the future of production. Companies that adopt these technologies can expect to see continued improvements in efficiency, quality, and safety, positioning them well in terms of global competition.

To learn more about how Automated Solutions Australia can enhance your manufacturing operations with state-of-the-art solutions, email us at sales@automatedsolutions.com.au, or phone us on 1800 ROBOTS. Alternatively you can use the contact form at the bottom of this page.

Embrace the future of manufacturing with ASA’s expertly engineered systems, today.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

Choose Another Recent News Story:

Advantages of Robotic Welding | Automated Picking | 6 Axis Welding Robots | FANUC Programming | Paint Finishing | Industrial Manufacturing | Robot Integration | Automation and Robotics | Industrial Applications | Automation Engineering | Benefits of Robots | Robots – A Guide |