Automated Picking | The Advantages

In the rapidly evolving landscape of warehouse management and logistics, automated picking systems are dramatically enhancing the efficiency and accuracy of operations. Hence Automated Solutions Australia (ASA) offers FANUC’s state-of-the-art robotic automated picking solutions tailored to the dynamic needs of modern industries.

The Need for Speed | Speed and Accuracy in Automated Picking Operations

Today’s production environments are intensely competitive, requiring operations to be faster, more reliable, and more flexible than ever before. The traditional manual picking processes are increasingly unable to meet these demands due to their inherent limitations in speed and consistency. This is where automated picking comes into play, offering unparalleled precision and reliability.

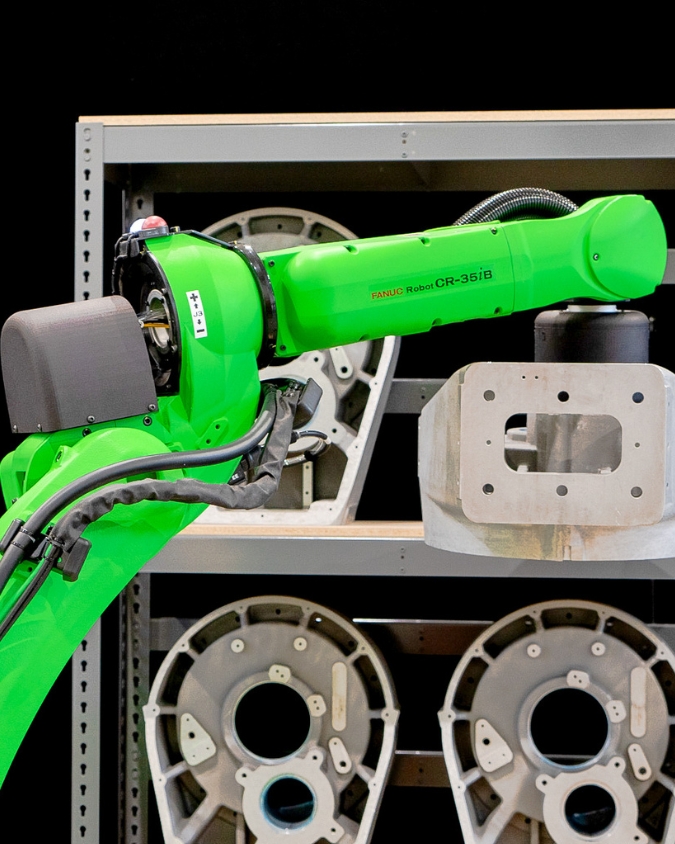

The Technological Edge | FANUC’s Automated Picking Solutions

FANUC, a leader in the automation industry, has developed specialised robots designed to optimise the automated picking process. These robots are engineered for high-speed, repetitive tasks such as sorting, inspecting, and precisely picking items from fast-moving conveyor belts. With capabilities that mimic human dexterity but with greater consistency and speed, FANUC’s robots are transforming the way warehouses operate.

Enhanced Productivity with Advanced Robotics for Automated Picking

One of the significant advantages of automated picking is the ability to operate continuously without fatigue. Unlike human workers, robots do not require breaks or shifts changes, allowing for non-stop operation that can significantly boost productivity. Additionally, these robots are programmed for optimal movement paths. Therefore minimising the time spent on each pick and increasing the overall throughput.

Automated Picking | Customisation and Flexibility

FANUC’s robotic solutions are highly adaptable, featuring customisable software that can be tailored to fit any production line setup. FANUC’s iRPickTool software, for instance, allows for easy integration and coordination of multiple robots. Therefore enhancing the system’s flexibility to adapt to various conveyor speeds, product types, and packaging needs. This adaptability makes automated picking systems suitable for a wide range of industries, from pharmaceuticals to electronics and more.

Automated Picking | Incorporating Vision Systems for Enhanced Sorting

Advanced vision systems are integral to modern robotic picking solutions, providing the robots with the ability to detect and identify items based on size, shape, or color. This capability is crucial for quality control and for operations where a high degree of accuracy is essential for sorting and selecting the correct items.

Safety and Labor Cost Reduction in Automated Picking

Implementing automated picking robotically also contributes to a safer work environment by reducing human exposure to potentially hazardous tasks. Additionally, it addresses the challenge of labor shortages and reduces the reliance on skilled labor by automating complex tasks. The long-term cost savings in terms of reduced labor expenses and decreased workplace injuries are significant, making automated picking an investment that pays dividends in safety and efficiency.

Automated Solutions Australia (ASA)

With over two decades of experience, ASA has a proven track record of successfully integrating robotic systems into diverse manufacturing settings. Our expertise in FANUC systems means we can offer bespoke solutions that maximise both the performance and ROI of automated picking technologies. ASA provides comprehensive support, from system design and installation to maintenance and training, ensuring your operations are always running smoothly.

If you’re ready to explore how automated picking can transform your operations, contact Automated Solutions Australia today at [email protected] or call us at 1800 ROBOTS. Transform your warehouse operations with the precision, speed, and reliability of our advanced robotic solutions.

Send an Enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Pick and Packaging | Material Removal Robots | Shot Blasting and Peening |

Choose Another Recent News Story:

Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Programming | Paint Finishing | Industrial Manufacturing | Robot Integration | Automation and Robotics | Industrial Applications | Automation Engineering | Benefits of Robots | Robots – A Guide |