Industrial Welding Robots by FANUC – Precision, Speed, and Efficiency with ASA

In today’s fast-paced manufacturing world robots are transforming the welding process by offering unmatched precision, speed, and efficiency. So as businesses face increasing demands for high-quality products and faster production times, they turn to FANUC industrial welding robots to streamline operations. FANUC, a global leader in industrial automation, provides cutting-edge robotic welding solutions that enhance productivity and ensure superior quality.

What is an Industrial Welding Robot?

An industrial welding robot is a highly advanced robotic system designed to automate welding tasks in manufacturing environments. These robots handle various welding processes, including arc welding, spot welding, as well as mig and tig welding, ensuring precise and consistent results every time. Unlike human welders, industrial welding robots operate around the clock, boosting production efficiency and reducing human error.

Why Choose FANUC Industrial Welding Robots?

FANUC, known for its robotic expertise, offers a range of welding robots that meet the needs of industries such as automotive, aerospace, and general manufacturing. Here’s why businesses choose FANUC for their welding automation needs:

Unmatched Precision and Consistency

Industrial welding robots deliver maximum precision. Moreover, these robots follow pre-programmed welding paths with incredible accuracy, resulting in uniform welds across large production runs. This consistency improves product quality and reduces the likelihood of costly defects and rework.

Enhanced Productivity and Speed

FANUC robots can operate 24/7, increasing production output. In addition, their ability to work without breaks reduces cycle times, while their high-speed welding process helps businesses meet tight deadlines and improve overall throughput. By incorporating FANUC welding robots, companies stay competitive in the global market.

Improved Worker Safety

Welding is a hazardous task, exposing workers to intense heat, fumes, and sparks. FANUC’s industrial welding robots take over these tasks, allowing workers to focus on higher-value jobs. By automating welding, robots create safer work environments and minimise health risks.

Cost Efficiency

While the initial investment into industrial welding robots is significant, the long-term savings are substantial. These robots reduce labour costs, minimise material waste, and eliminate errors caused by human welders. As a result, businesses see a quick return on investment, making FANUC welding robots an economically sound choice.

Flexibility and Scalability with Industrial Welding Robots

Industrial welding robots adapt to a wide range of welding applications. Whether businesses need to weld large automotive parts or smaller components for electronics, robots can be reprogrammed or equipped with different tools to handle various tasks. As businesses grow, FANUC robots scale to meet new production needs, offering long-term value.

FANUC’s Industrial Welding Robots in Action

ARC Mate Series

The FANUC ARC Mate series offers versatility and precision for arc welding applications. These robots excel in automotive, heavy machinery, and other industries, providing high-quality, efficient welding solutions. With various payload capacities and arm reaches, the ARC Mate robots tackle any welding task.

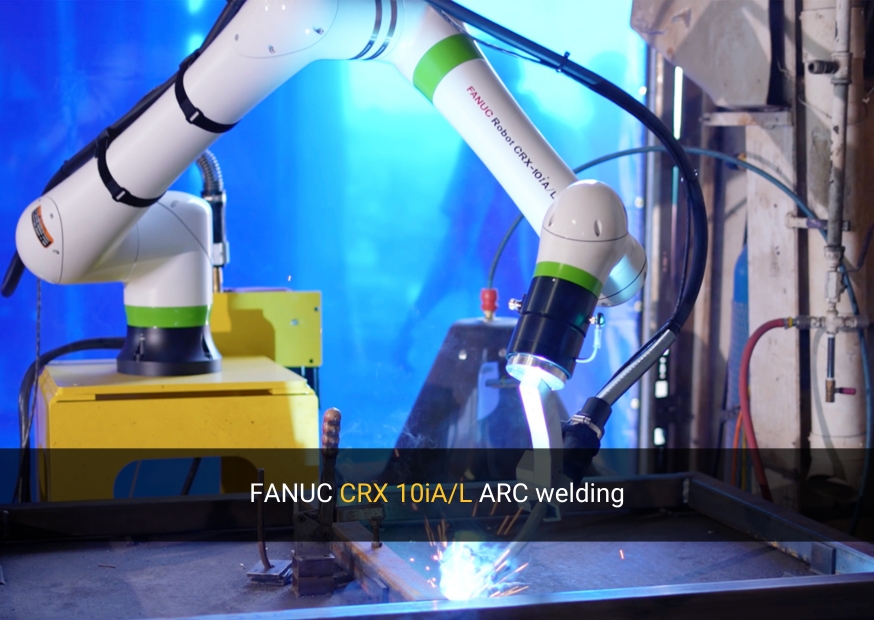

CRX-10iA Robotic Welder

The FANUC CRX-10iA is a collaborative robot (cobot) that strikes a perfect balance between flexibility and precision for welding tasks. Its ease of programming allows this robot to work alongside human operators in shared spaces, offering an ideal solution for small to medium-sized businesses looking to integrate robotic welding quickly.

Industries Benefiting from FANUC Industrial Welding Robots

Automotive – FANUC’s robots perform tasks like spot welding, seam welding, and arc welding for body panels and components in automotive manufacturing.

Aerospace – FANUC welding robots handle critical components requiring high precision, such as turbine blades and fuselage parts in aerospace manufacturing.

General Manufacturing – FANUC robots handle various welding tasks, from welding metal parts to assembling industrial machinery, across general manufacturing applications.

Industrial robots provide businesses with powerful solutions to enhance their welding processes. With unmatched precision, speed, safety, and cost-efficiency, FANUC robots transform how industries approach welding. By integrating FANUC’s robotic welding systems into production lines, businesses improve product quality, reduce operational costs, and stay competitive. Embrace the future of automation with FANUC robots, and elevate your business to new levels of productivity and precision.

At Automated Solutions Australia (ASA), we have been integrating FANUC robots for over 20 years. To speak to Australia’s FANUC experts, use the contact form below, or phone us on 1800 ROBOTS.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Materials Handling Robots |

More (Recent) News Stories from Automation Solutions Australia:

Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers |Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry | Automatic Systems | Automated Manufacturing System | Auto Robots | Automatic Material Handling | Picking Robots | CNC Machinery Solutions | Australia Wide Automation | Automatic Coating | Collaborative Robots in Manufacturing | Automatic Solutions | Automated Robot | Robotics Integrators | Robotic Solutions | PLC Industrial Automation | Automated Materials Handling | Robots Used in Industry | Cobot Integration | Palletisers | Robotic Spot Welding | Industrial Robots for Sale | Robots in Business | Collaborative Welding Robots | Robot Solution | Adelaide Automation | Shot Blasting Services | Cobots and Robots | Industrial Robotics Companies |