Arc Welding – Versatility Across Diverse Metal Compositions

The World of ARC Welding

ARC welding, a metal joining technique, harnesses the power of electrical arcs to meld metals together seamlessly. Consequently, the fundamental principle revolves around positioning an electrode near the metal surface to be joined, initiating an electrical arc through voltage application. So the arc, pulsating with intense heat, bridges the gap between the electrode and the workpiece, causing the metals to liquefy and merge.

The Mechanics of ARC Welding

ARC welding operates by leveraging electrical arcs to induce metal fusion. Thus, by applying a voltage across two conductive electrodes, an arc is ignited, this then goes on to generate temperatures exceeding 3000°C. Specifically, this intense heat liquefies the metals, forming a molten pool at the arc’s focal point. So as the arc traverses along the metal surfaces, the molten pool solidifies, yielding a robust weld.

Origins of ARC Welding

Arc welding was initially introduced by Nikolai Benardos, who first showed the technique of metal arc welding using a carbon electrode at the International Exposition of Electricity in Paris in 1881. This method was later patented in 1887, in collaboration with Stanisław Olszewski.

Diverse Applications of ARC Welding

The versatility of ARC welding renders it indispensable across a myriad of industries, serving as a linchpin in the fabrication and repair of metallic components. In the automotive sector, arc welding is used to join heat shields, exhaust systems, and hydraulic lines to the vehicle’s frame. In addition, office desks, file cabinets, and shelving units made of metal are frequently assembled through welding. Similarly, the construction of heating, ventilation, and air conditioning (HVAC) systems typically involves welding techniques. Therefore, from automotive manufacturing to industrial piping, shipbuilding, and structural steel erection, ARC welding permeates diverse sectors, seamlessly integrating metal parts with precision and durability.

Applications include:

Maintenance and repair of metallic components

Shipbuilding for constructing watertight seals

Industrial piping fabrication

Vehicle assembly in automated manufacturing plants

And more!

Materials Used in ARC Welding

From magnesium and aluminium, stainless steel and titanium, ARC welding accommodates an extensive array of metallic substrates. Each material presents unique challenges and considerations, necessitating tailored welding approaches to ensure optimal results.

Advantages of ARC Welding

Firstly, the sheer versatility across diverse metal compositions

Secondly, the ability to operate effectively, despite imperfect welding conditions

Thirdly, arc welding is accessible and affordable

You also achieve excellent results

Lastly, you can lower efficiency

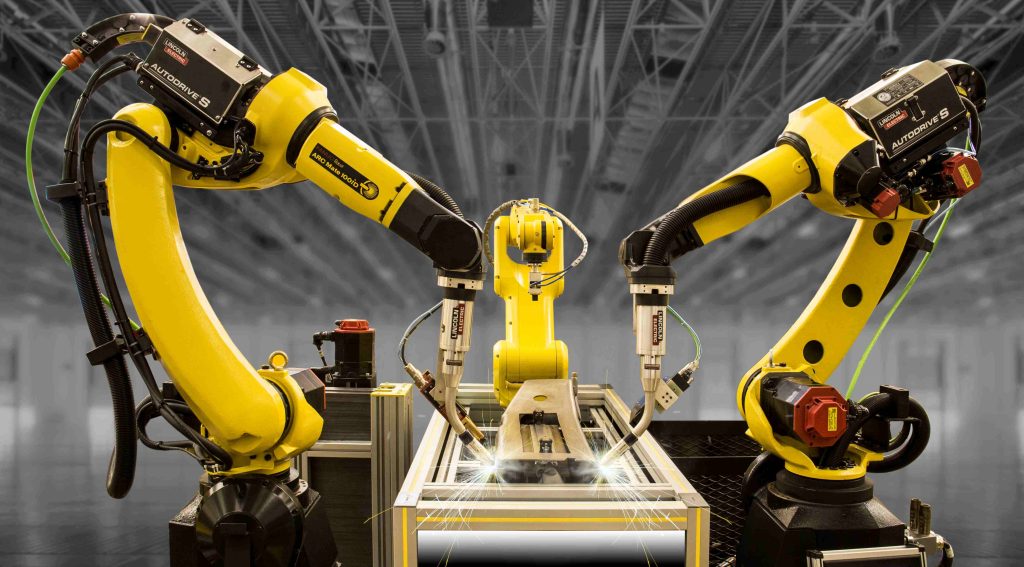

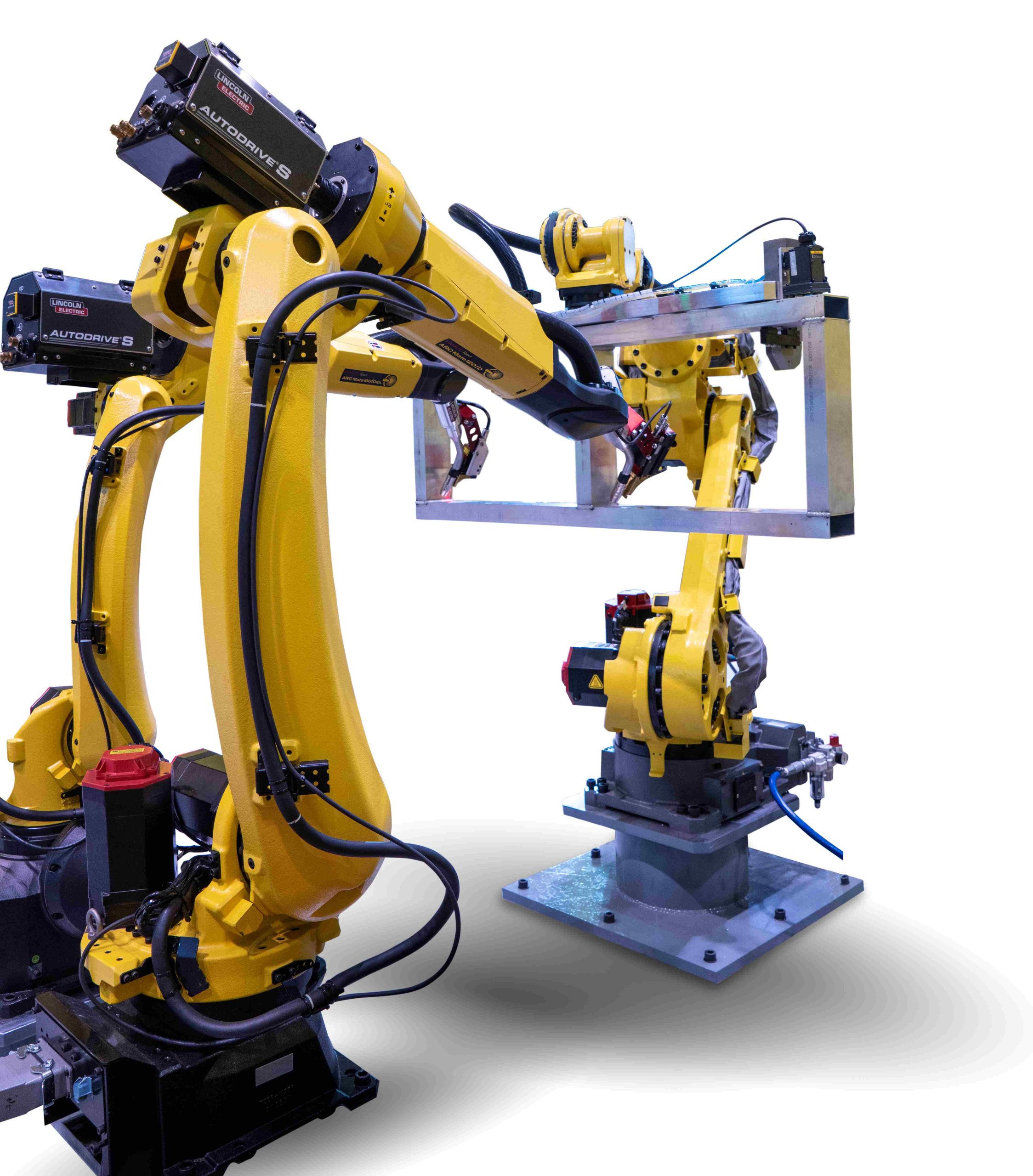

Elevate Your ARC Welding Efficiency with ASA

Automated Solutions Australia (ASA) offers cutting-edge ARC welding solutions powered by FANUC robots. With payloads ranging from 7 kg to 25 kg, these robots excel in various industrial welding applications, including MIG, TIG, plasma, and laser cutting. Backed by a team of FANUC robot specialists, ASA delivers comprehensive support, from concept to installation and beyond, empowering Australian businesses to achieve automation excellence on the global stage. Contact ASA today and unleash the full potential of automation.

At ASA we’ve been in the automation industry for over 20 plus years. You can trust us as your go to experts in Australia, for all things automation.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |