Elevate Your Manufacturing with a Dispensing Robot

In the fast-paced world of modern manufacturing, achieving precision and efficiency is crucial. One of the most effective ways to attain both is through the implementation of a dispensing robot. This innovative technology allows for the accurate application of materials such as adhesives, sealants, and other fluids, ensuring consistent and reliable results that traditional methods simply cannot achieve.

]Dispensing Robot | The Benefits

A dispensing robot offers a multitude of advantages across various industries, including automotive, electronics, and consumer goods. With the ability to precisely control the amount and placement of materials, manufacturers can significantly enhance product quality while simultaneously reducing waste.

Moreover, this level of precision is essential for meeting stringent industry standards and ensuring customer satisfaction. As a result, businesses that adopt dispensing robots often see improved operational performance and a stronger competitive edge in the market.

Unmatched Precision and Consistency with a Dispensing Robot

One of the standout features of a dispensing robot is its ability to apply materials with exact precision. This minimises the risk of errors and variations that frequently occur with manual processes. For instance, when used within the automotive assembly, it can accurately apply adhesives, ensuring every component is securely bonded without excess material.

Increased Efficiency with a Dispensing Robot

Automation also dramatically speeds up the dispensing process, enabling higher throughput and shorter production times. This increased efficiency translates to significant cost savings, allowing businesses to remain competitive in an ever-evolving marketplace. By utilising a dispensing robot, manufacturers can optimise their workflows and achieve faster turnaround times.

Flexibility in Application with a Dispensing Robot

Another significant advantage is flexibility. You can easily program these systems to handle a wide variety of materials and application patterns. Whether you’re dealing with thick adhesives or thin sealants, a dispensing robot can be tailored to meet your specific requirements.

Reduced Waste with a Dispensing Robot

Precise control over material application means less waste and lower material costs. This is not only beneficial for your bottom line but also supports sustainability efforts by minimising excess usage. As businesses increasingly prioritise eco-friendly practices, incorporating a dispensing robot can play a pivotal role in achieving those goals.

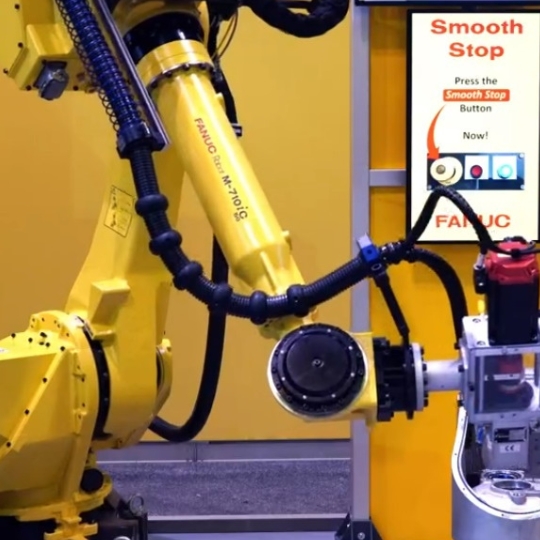

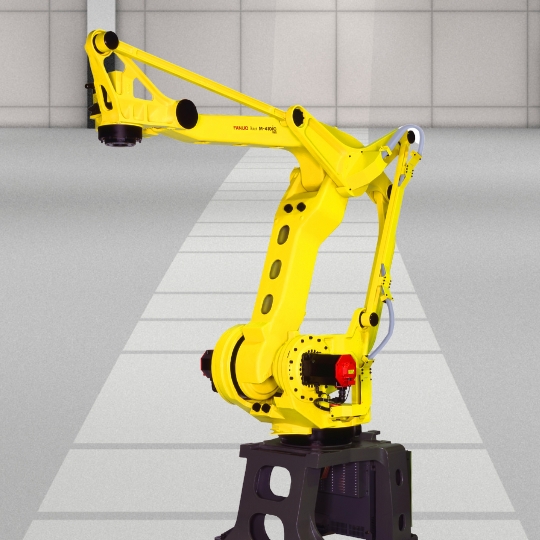

Why Choose FANUC for Your Dispensing Robot Needs?

At Automated Solutions Australia (ASA), we integrate FANUC robots for a wide range of applications, including dispensing. With over 20 years of experience, our expert team can design and implement tailored automation solutions that enhance productivity and efficiency.

Whether you need to improve the accuracy of adhesive application in automotive assembly or ensure consistent sealant dispensing in electronics manufacturing, we can create a bespoke solution that fits your needs.

Get Started Today with ASA

Are you ready to elevate your manufacturing processes? Contact Automated Solutions Australia today to discover how our FANUC robot integration can benefit your operations. Let’s work together to optimise your manufacturing for maximum efficiency and quality.

Embrace the future of manufacturing with robotic dispensing and take your business to new heights!

Send an enquiry:

More (Recent) News Stories from Automation Solutions Australia:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers | Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry |