Robotic Laser Welding: What It Involves

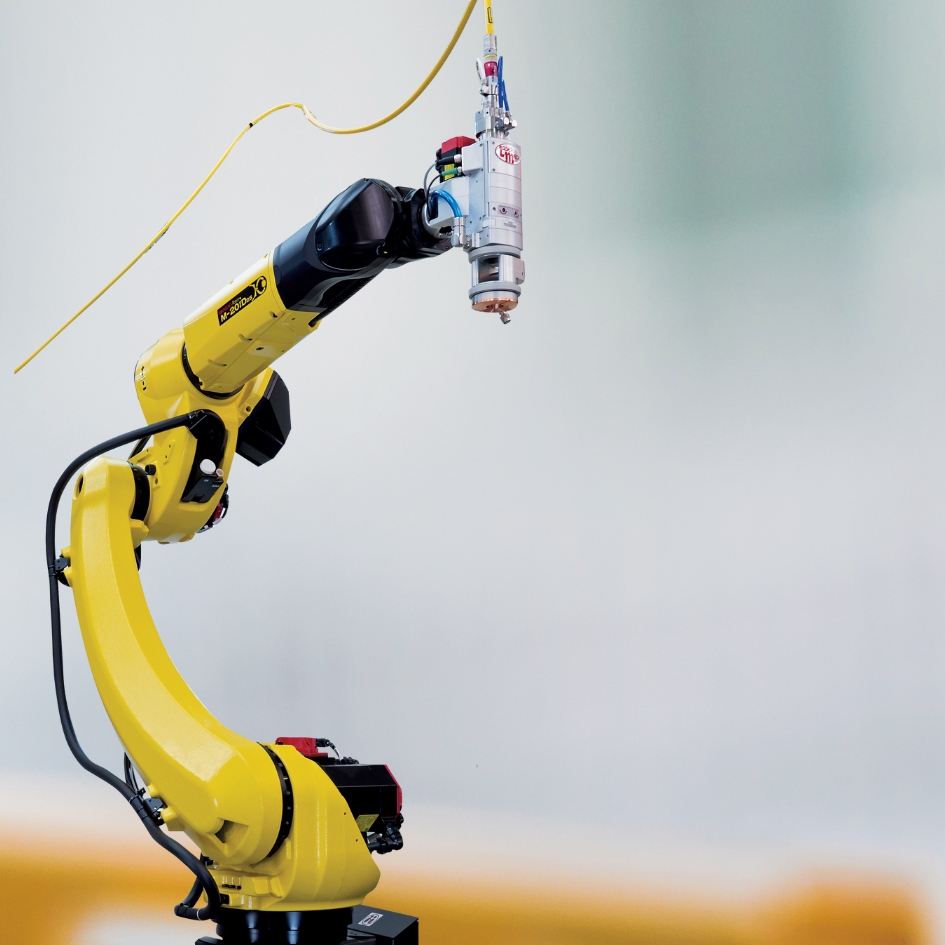

Robotic laser welding is a high-precision joining process that uses a focused laser beam, making it ideal for many industries. Specifically, at Automated Solutions Australia (ASA), we integrate FANUC robots for laser welding, ensuring you receive the highest quality and efficiency.

How Does Laser Welding Work?

Laser welding involves generating energy through a high-performance laser, guided to the processing location using flexible optical fibers. So the laser power is focused on a small spot, melting the workpiece and welding the components with minimal thermal distortion. Therefore this process is perfect for high-speed, narrow weld seams.

The Benefits of Robotic Laser Welding Over Traditional Welding

Robotic laser welding offers numerous advantages over traditional welding processes, particularly for high-precision applications:

- Firstly, laser welding beams create deep and accurate welds, reducing the need for touch-ups or rework.

- Laser Welding is suitable for various applications, including those requiring high accuracy and speed.

- Smaller heat-affected zones minimise distortion, regardless of the metal type.

- Finally, laser welding produces cleaner results, improving the overall quality.

Advances in Robotic Laser Welding Technology

Recent advancements in vision technology, scanner controls, and real-time interfaces for optical sensors have significantly enhanced this application. Hence these innovations enable greater accuracy and efficiency, making robotic laser welding a more viable option for complex applications.

Key Applications for Robotic Laser Welding

Robotic laser welding is ideal for a variety of industries, including:

Automotive

Aerospace

Electronics

Healthcare

and more

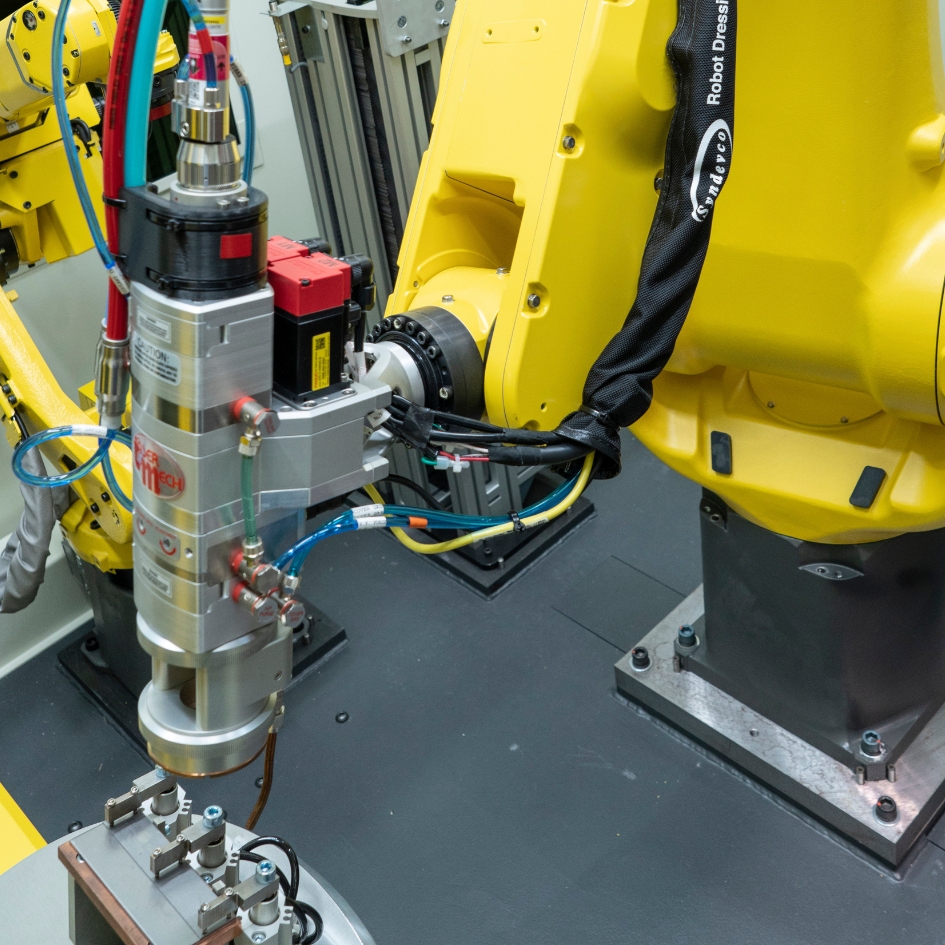

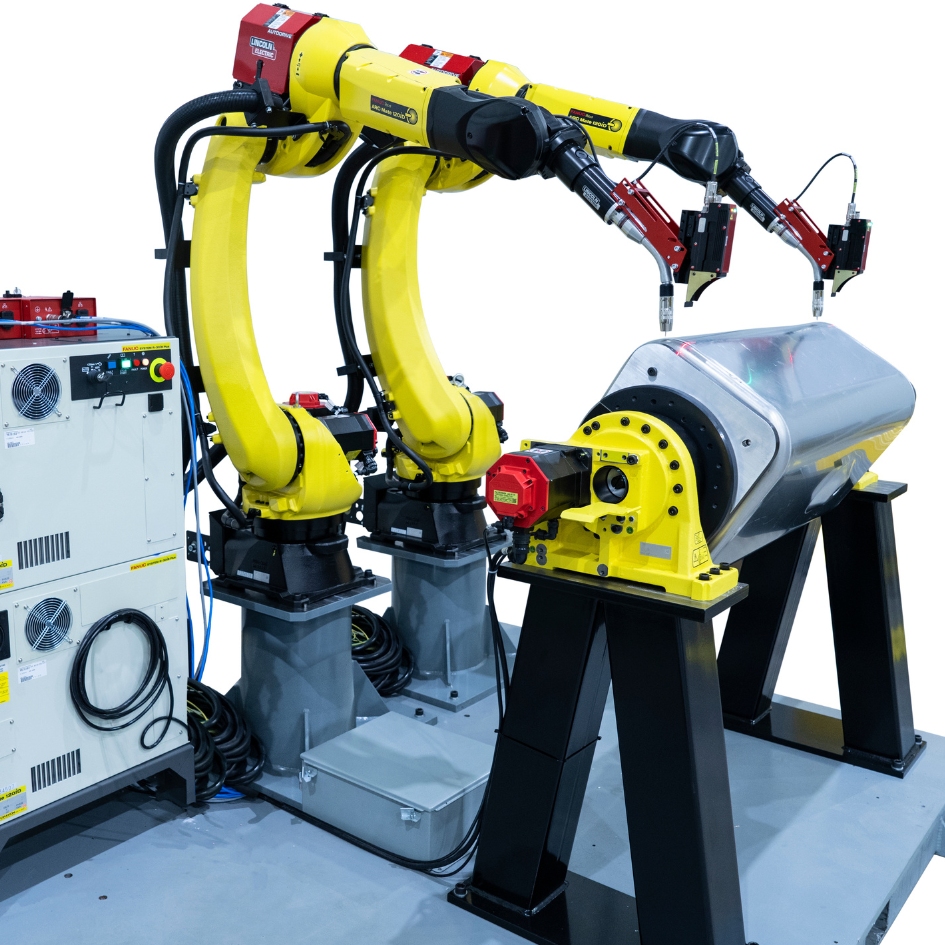

Elements of a Robotic Laser Welding Cell

A robotic laser welding cell comprises several critical components:

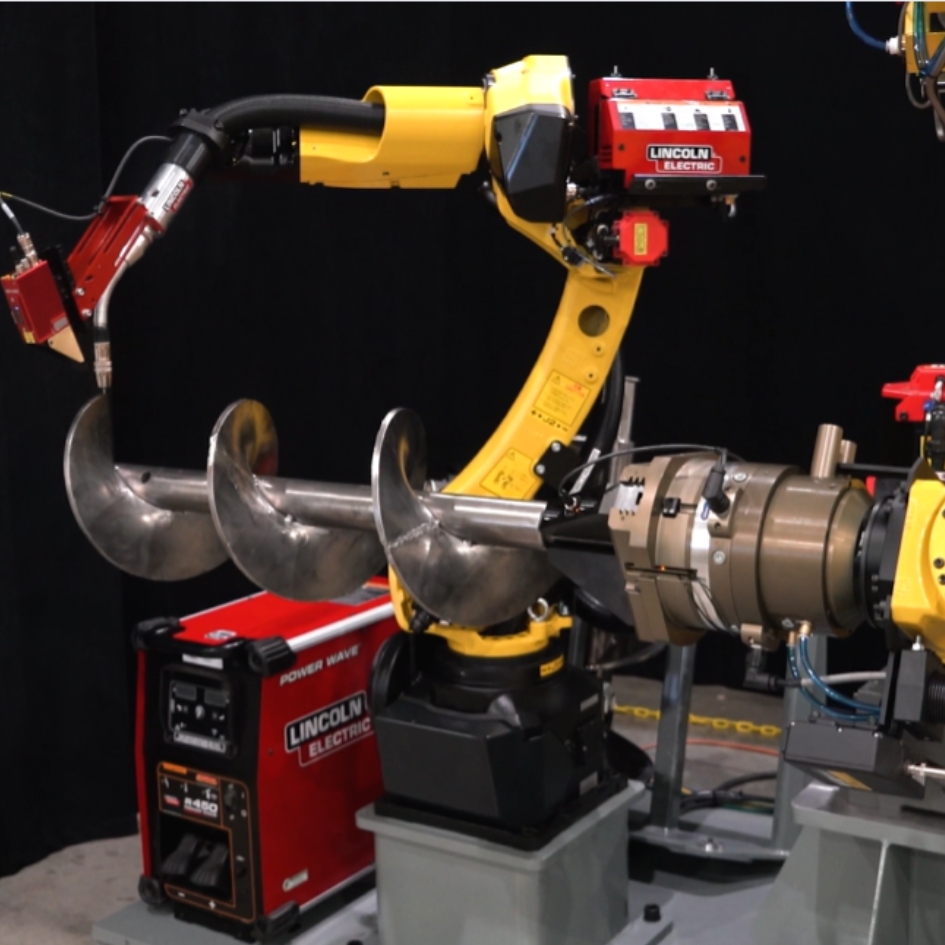

The Robot/s: The robots are responsible for applying the weld, with various models offering different design characteristics based on reach, payload, speed, and precision.

The Laser: Since the laser generates the welding beam, types are chosen based on material and weld requirements.

Cooling System: Although essential for maintaining functional temperatures, it also prevents heat damage.

Part Presentation: Such methods for presenting parts to the robot include conveyors, jigs, turntables, clamps, and other robots.

Sensing/Monitoring Systems: This includes temperature sensors, beam and seam trackers, and vision systems for quality control and safety.

Safety Measures: Enclosures, light curtains, safety scanners, and lock-out/tag-out systems are vital for protecting employees.

Why Choose ASA for Your Robotic Laser Welding Needs?

Automated Solutions Australia (ASA) is an Australian integrator of FANUC robots for a number of robotic applications, including laser welding. As such, our industrial engineering team specialises in everything from concept and design to installation, programming, and support. In summary, we are committed to helping Australian businesses achieve their automation goals, enabling them to compete on the global stage.

Ready to Transform Your Welding Process?

If you’re looking for an efficient robotic laser welding robot, get in touch with ASA today. Without a doubt, our team of FANUC robot specialists will help you find the perfect robotic laser welding solution for your manufacturing needs. So dont hesitate to contact us at 1800-ROBOTS or email us at [email protected].

The below video is a FANUC ARC Mate 100iD and FANUC R1000iA/100F demonstrating Laser Seam Tracking.

Send an Enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

For More Recent News Stories from ASA:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Automation and Robotics | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Hnadling in Australia | Robotic Assembly Guide | A Guide to the History of Robots |