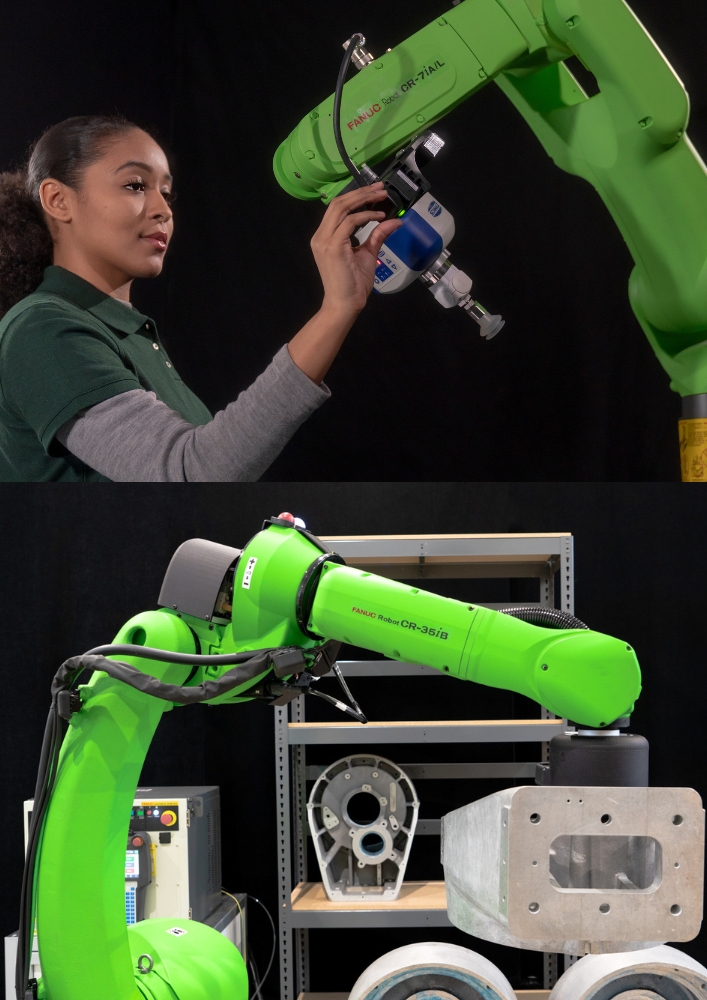

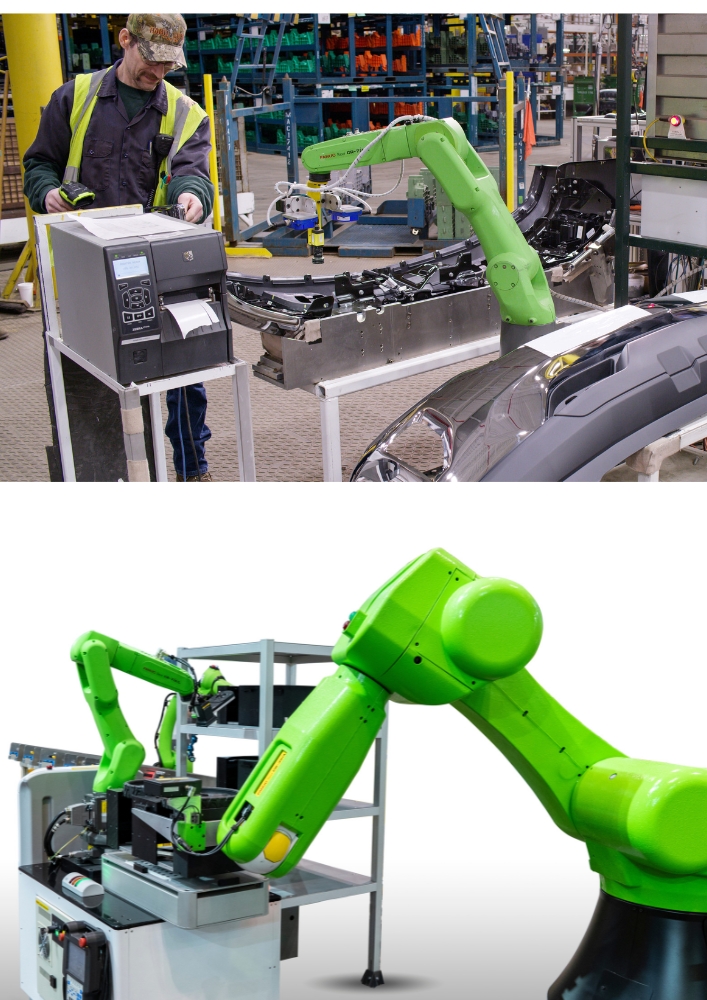

The FANUC CR series brings the perfect balance of precision, safety, and efficiency to your workplace. Designed with adaptability in mind, these collaborative robots (cobots) integrate seamlessly into various industrial processes, making automation accessible for businesses of all sizes.

What Is the FANUC CR Series?

The FANUC CR range includes versatile collaborative robots with a wide range of payload capacities, from small and lightweight models to heavy-duty cobots. Moreover, each robot in the series prioritises safety, productivity, and adaptability, enabling businesses to automate repetitive tasks while ensuring a secure environment for human workers.

Key Features of FANUC CR Robots

Wide Payload Range: Handles from 4kg to 35kg, making it ideal for a variety of applications.

Advanced Safety Features: Built-in sensors detect contact with humans and stop the robot instantly, eliminating the need for safety barriers.

Easy Programming: User-friendly interfaces allow for quick setup and operation without extensive training.

Durable and Reliable: Engineered for high performance, even in demanding environments.

Flexible Integration: Easily adapts to existing systems and processes.

Applications of FANUC CR Robots

FANUC CR cobots are designed for a wide range of tasks, including:

Material Handling: Automate the movement of parts and products, reducing manual labour.

Assembly: Perform precise and repetitive assembly tasks with accuracy.

Pick and Place: Efficiently pick and position items in production lines.

Inspection: Ensure consistent quality through automated checks.

Packaging: Streamline the packing process to improve productivity.

Benefits of the FANUC CR Range

First and foremost, these robots enhance workplace safety. The collaborative design ensures that robots can work safely alongside human operators. Additionally, they boost productivity by automating time-consuming tasks, freeing up your workforce for higher-value activities. What’s more, they improve accuracy by achieving consistent results with repeatable precision. Finally, the FANUC CR range helps reduce costs by lowering operational expenses, minimising errors, and optimising labour.

Why Choose FANUC?

The FANUC CR series offers a reliable solution for businesses looking to adopt automation without overhauling their existing setups. Unlike other solutions, these cobots are intuitive, versatile, and designed to enhance both efficiency and safety. Whether you’re a small business exploring automation or a large manufacturer seeking to optimise processes, FANUC CR robots deliver exceptional results.

How Automated Solutions Australia Can Help

At Automated Solutions Australia (ASA), we specialise in integrating FANUC CR robots into diverse industries. With over 20 years of experience, our team offers end-to-end services, including consultation, system design, installation, programming, and ongoing support.

Let us help you streamline your operations, boost productivity, and create a safer, more efficient workspace with the FANUC CR range.

📞 Call us today at 1800 ROBOTS

📧 Email us at sales@automatedsolutions.com.au

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Materials Handling Robots |

More (Recent) News Stories from Automation Solutions Australia:

Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers |Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry | Automatic Systems | Automated Manufacturing System | Auto Robots | Automatic Material Handling | Picking Robots | CNC Machinery Solutions | Australia Wide Automation | Automatic Coating | Collaborative Robots in Manufacturing | Automatic Solutions | Automated Robot | Robotics Integrators | Robotic Solutions | PLC Industrial Automation | Automated Materials Handling | Robots Used in Industry | Cobot Integration | Palletisers | Robotic Spot Welding | Industrial Robots for Sale | Robots in Business | Collaborative Welding Robots | Robot Solution | Adelaide Automation | Shot Blasting Services | Cobots and Robots | Industrial Robotics Companies | Industrial Welding Robots | Automatic Blasting Machine | Machine Tending Robot |