In today’s fast-paced manufacturing environment, businesses constantly seek ways to improve efficiency, reduce downtime, and boost production quality. As a result, collaborative robots (cobots) like the FANUC CRX are transforming automation. Offering flexibility, ease of use, and a broad range of applications, the FANUC CRX series is changing the way manufacturers approach automation.

What is the FANUC CRX?

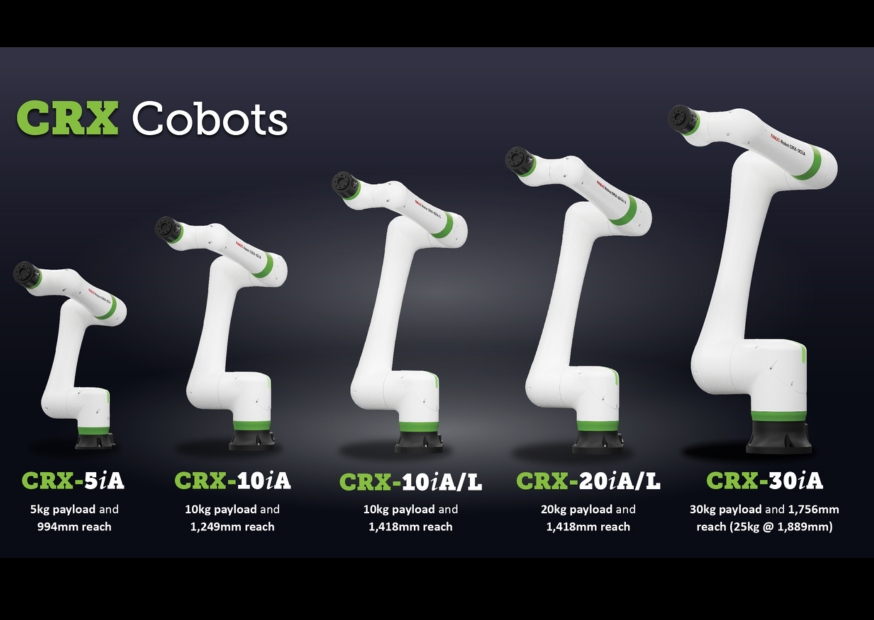

The FANUC CRX series is a line of collaborative robots designed to work alongside human workers safely, without the need for safety cages or barriers. These robots handle various tasks such as material handling, assembly, picking and placing, and inspection with precision and reliability. The FANUC CRX features an easy-to-program interface, making it suitable for both beginners and seasoned robotic engineers.

Key Features of FANUC CRX Robots

Easy Programming and Integration: The FANUC CRX stands out for its user-friendly programming interface. Unlike traditional industrial robots, the CRX series allows operators to set up and program tasks quickly with minimal training. With the intuitive FANUC CRX Interface and touchscreen, operators can teach the robot new tasks and make real-time adjustments to enhance workflow efficiency.

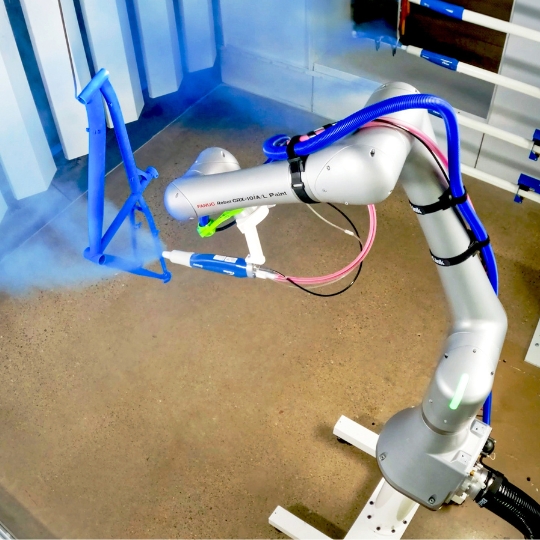

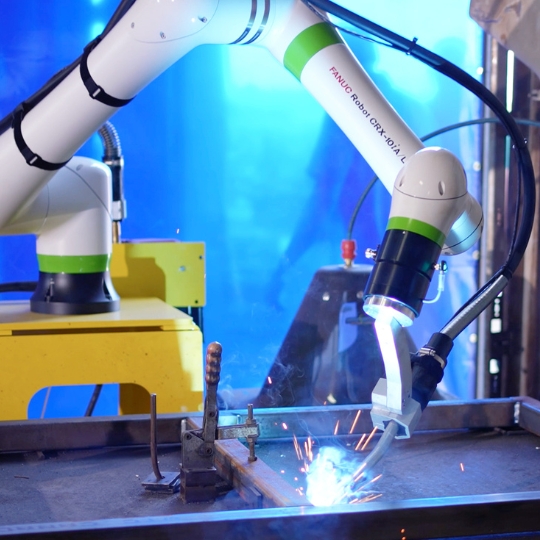

Flexible and Collaborative: The FANUC CRX series is built for flexibility in any workspace. These cobots handle a variety of applications, such as picking and placing, assembly, inspection, welding, machine tool tending and more. Their compact size and lightweight design make it easy to integrate them into existing production lines, improving efficiency without requiring major changes to current setups. Additionally, the CRX robots work alongside human operators without the need for safety barriers, fostering a safer and more dynamic working environment.

Enhanced Precision and Safety: FANUC CRX robots deliver high precision, with repeatability of ±0.05mm, making them perfect for tasks that require accuracy. They come with advanced safety features, ensuring safe operation alongside human workers. Built-in sensors detect unexpected obstacles or human contact, immediately stopping or slowing down the robot’s movements to prevent accidents.

Versatility Across Industries: The FANUC CRX fits various industries, including electronics, automotive, food and beverage, and consumer goods. Whether handling small parts, assembly, or packaging, the CRX cobot adapts to meet each industry’s unique needs, offering businesses a valuable tool for boosting productivity and reducing operational costs.

Why Choose FANUC CRX for Your Business?

Increase Productivity

By integrating FANUC CRX robots, businesses can improve efficiency, reduce human error, and speed up production cycles. These robots handle repetitive and time-consuming tasks, allowing human workers to focus on higher-value activities.

Cost-Effective Automation

FANUC CRX robots offer a cost-effective automation solution. With low installation costs and the flexibility to scale, these robots provide value for businesses of all sizes, from small enterprises to large manufacturers.

Ease of Use

The user-friendly interface and simple programming make it easy for operators to integrate the FANUC CRX into their operations. This reduces the need for specialised training, accelerating the return on investment.

Improve Workplace Safety

The FANUC CRX robot’s collaborative nature allows it to work safely in environments where humans are present. Equipped with sensors and safety features, the robot slows or stops its movements if it detects any potential hazards, creating a safer work environment.

Applications

The FANUC CRX series is versatile and can be used in various applications, including:

Material Handling: Automate the movement of parts, materials, and components, reducing reliance on manual labour.

Assembly: Quickly and accurately assemble components with high precision and speed.

Packaging: Streamline the process of packing and handling products for shipping or storage.

Inspection and Quality Control: Conduct quality checks and inspections to meet product standards.

Pick and Place: Efficiently pick and place items on production lines or into packaging.

How Automated Solutions Australia Can Help You Integrate FANUC CRX Robots

At Automated Solutions Australia, we specialise in providing FANUC robots to businesses across Australia. Our expert team offers full-service solutions, from consultation and design to programming, installation, and ongoing support.

We understand that every business has unique needs. That’s why we deliver bespoke solutions to help you improve productivity, reduce costs, and enhance safety. Whether you need a FANUC CRX robot for material handling, assembly, welding, machine tending, or inspection, we’re here to help you unlock the potential of automation.

The FANUC CRX series is revolutionising the way businesses approach automation. With its flexibility, ease of use, and collaborative design, the CRX robot is the ideal solution for companies looking to enhance operations, improve safety, and boost productivity. As industries evolve, the FANUC CRX will continue to play a vital role in driving innovation and efficiency across Australian manufacturing environments.

If you’re ready to integrate FANUC CRX robots into your operations, contact Automated Solutions Australia today. Let us help you achieve your automation goals.

📞 1800 ROBOTS

📧 sales@automatedsolutions.com.au

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Materials Handling Robots |

More (Recent) News Stories from Automation Solutions Australia:

Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers |Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry | Automatic Systems | Automated Manufacturing System | Auto Robots | Automatic Material Handling | Picking Robots | CNC Machinery Solutions | Australia Wide Automation | Automatic Coating | Collaborative Robots in Manufacturing | Automatic Solutions | Automated Robot | Robotics Integrators | Robotic Solutions | PLC Industrial Automation | Automated Materials Handling | Robots Used in Industry | Cobot Integration | Palletisers | Robotic Spot Welding | Industrial Robots for Sale | Robots in Business | Collaborative Welding Robots | Robot Solution | Adelaide Automation | Shot Blasting Services | Cobots and Robots | Industrial Robotics Companies | Industrial Welding Robots | Automatic Blasting Machine |