Robotics and Manufacturing | Efficiency and Precision

In today’s fast-paced and competitive industrial landscape, businesses constantly seek ways to improve efficiency, reduce downtime, and boost production quality. As a result, robotics and manufacturing are becoming inseparable, driving industry advancements and ensuring companies remain competitive. The integration of robotic technology into manufacturing processes is no longer a futuristic vision, but a present-day reality that delivers real, measurable benefits to businesses.

What Role Does Robotics Play in Manufacturing?

The primary role of robotics in manufacturing is to enhance efficiency, improve precision, improve safety, and reduce costs across various sectors. Industrial robots are designed to automate repetitive, dangerous, or time-consuming tasks, allowing human workers to focus on higher-value activities. Furthermore, from automated assembly lines to welding, machine tool tending, painting, and packaging, robots streamline operations and create consistent, high-quality outputs with minimal downtime. With the integration of robotic systems, manufacturers can meet the ever-increasing demand for speed, quality, and precision, while also reducing the potential for human error.

Benefits of Robotics in Manufacturing

Enhanced Precision and Consistency

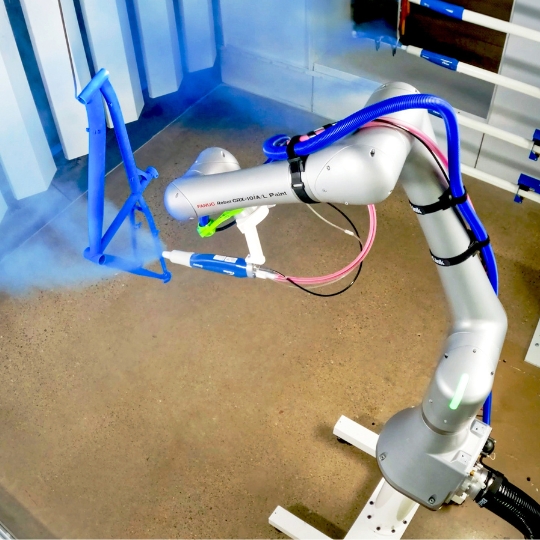

One of the most significant advantages of incorporating robotics into manufacturing is the level of precision robots bring to the table. Robots are designed to work with a high degree of accuracy and repeatability, making them ideal for tasks that demand consistent results. As a result, this leads to higher quality products, reduced waste, and less need for rework. For instance, welding, painting, and assembly applications benefit from robotic systems that provide exact, uniform results every time.

Increased Productivity

Robots can work around the clock, boosting production rates while reducing downtime. Unlike human workers, robots do not require breaks, rest, or holidays, allowing businesses to run continuous operations. This increases throughput, maximising production cycles and ensuring companies meet tight deadlines without compromising quality. Therefore, by integrating robotic systems into manufacturing, businesses can drive faster production and higher output with consistent results.

Benefits Continued

Cost Savings

While the initial investment in robotics and manufacturing technology may seem high, the long-term benefits far outweigh the costs. Robots reduce labour costs significantly, especially for repetitive or hazardous tasks that would otherwise require multiple human operators. Moreover, robotic systems minimise errors, improving product quality and reducing the risk of costly mistakes. As a result, businesses can optimise operations, decrease waste, and increase throughput, all of which contribute to significant cost savings in the long term.

Improved Workplace Safety

Safety is a top priority in manufacturing environments, and robotics plays a key role in reducing workplace accidents. Robots are well-suited to handle dangerous or repetitive tasks such as lifting heavy objects, welding, or operating in hazardous environments. Consequently, automating these processes can lower the risk of injury for human workers and create safer working conditions. This leads to higher employee morale and increased productivity, as workers can focus on more complex tasks while robots handle the heavy lifting.

Flexibility and Scalability

Robotic systems offer unparalleled flexibility, making them ideal for a wide variety of applications across different industries. Whether it’s assembly, material handling, packaging, machine tending, or quality inspection, robots can be quickly reprogrammed and adapted to handle different tasks. Thus providing businesses with the scalability they need to respond to changing demands and market conditions. Additionally, this flexibility ensures that robots can be used across multiple product lines or departments. Thus ensuring a strong return on investment.

Robotics in Manufacturing | Industry Applications

The applications of robotics in manufacturing span numerous industries, from automotive to electronics and food production. Here are some key areas where robotics is making a significant impact:

Assembly: Robots handle delicate assembly tasks with precision, whether it’s installing small components in electronics or assembling automotive parts.

Material Handling: Robots are used to move, sort, and package materials efficiently, eliminating the need for manual lifting and improving overall workflow.

Welding: Robotic welding systems provide high-speed, precise, and repeatable welding capabilities for industries such as automotive and aerospace.

Painting and Coating: Automated painting and coating robots ensure consistent coverage, delivering high-quality finishes with minimal waste.

How Automated Solutions Australia Can Help

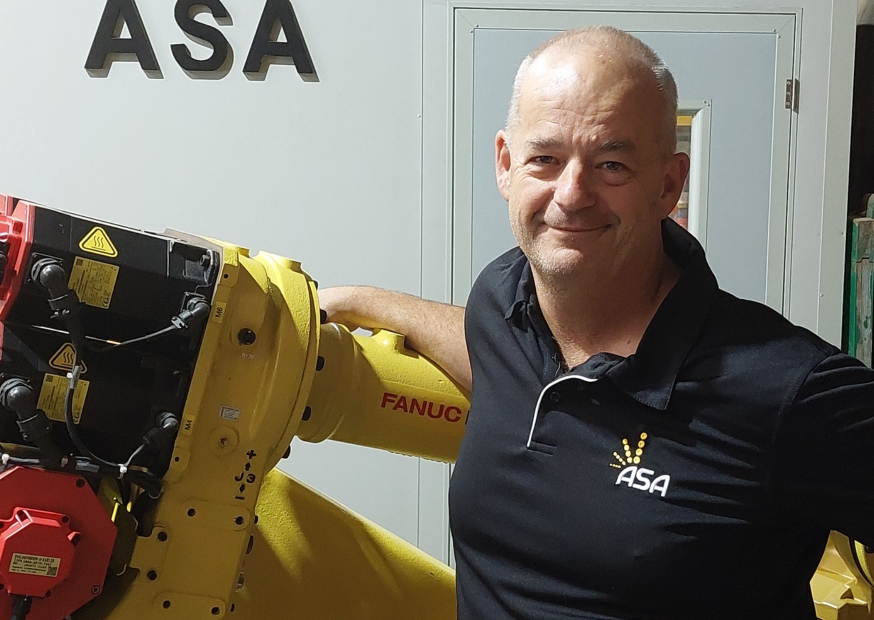

At Automated Solutions Australia (ASA), we specialise in integrating robotics and manufacturing technologies to optimise your operations. Our expert team works closely with businesses to design bespoke solutions that enhance productivity, improve product quality, and reduce operational costs. With extensive experience in integrating FANUC robots, we offer a wide range of industrial and collaborative robots perfect for applications such as assembly, welding, material handling, and more.

We understand that every business is unique. Therefore, we deliver tailored solutions to meet your specific needs, ensuring that you get the most out of your investment in robotics and manufacturing. From consultation and system design to installation, programming, and ongoing support, we’re with you every step of the way.

Get in Touch

At Automated Solutions Australia, we are committed to helping businesses across Australia integrate robotics into their manufacturing processes. Our expertise in robotic automation will help you unlock new levels of productivity and efficiency, allowing your business to thrive in an increasingly automated world.

Ready to take your manufacturing process to the next level with robotics? Contact us today to find out how we can help you optimise your operations and stay ahead of the competition.

📞 1800 ROBOTS

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Materials Handling Robots |

More (Recent) News Stories from Automation Solutions Australia:

Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers |Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry | Automatic Systems | Automated Manufacturing System | Auto Robots | Automatic Material Handling | Picking Robots | CNC Machinery Solutions | Australia Wide Automation | Automatic Coating | Collaborative Robots in Manufacturing | Automatic Solutions | Automated Robot | Robotics Integrators | Robotic Solutions | PLC Industrial Automation | Automated Materials Handling | Robots Used in Industry | Cobot Integration | Palletisers | Robotic Spot Welding | Industrial Robots for Sale | Robots in Business | Collaborative Welding Robots | Robot Solution | Adelaide Automation | Shot Blasting Services | Cobots and Robots | Industrial Robotics Companies | Industrial Welding Robots | Automatic Blasting Machine | CRX |