Robotics Definition | A Comprehensive Overview of Modern Technology

In today’s fast-paced world, robotics revolutionises industries across the globe. But what does robotics definition really mean? Simply put, robotics focuses on designing, building, and operating robots. These machines carry out tasks autonomously or semi-autonomously, enhancing efficiency, precision, and safety in various sectors.

What is Robotics? Understanding the Robotics Definition

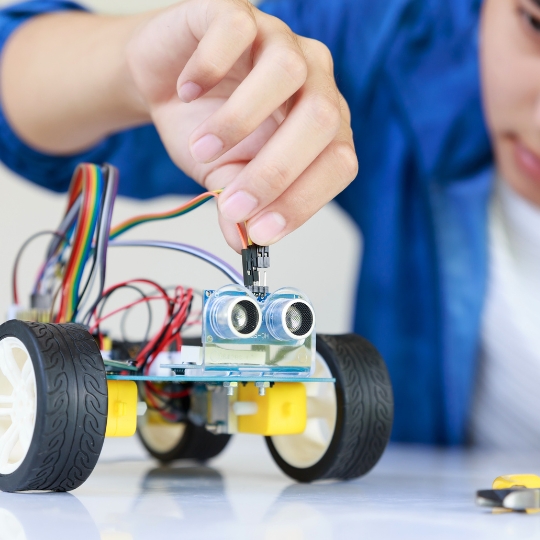

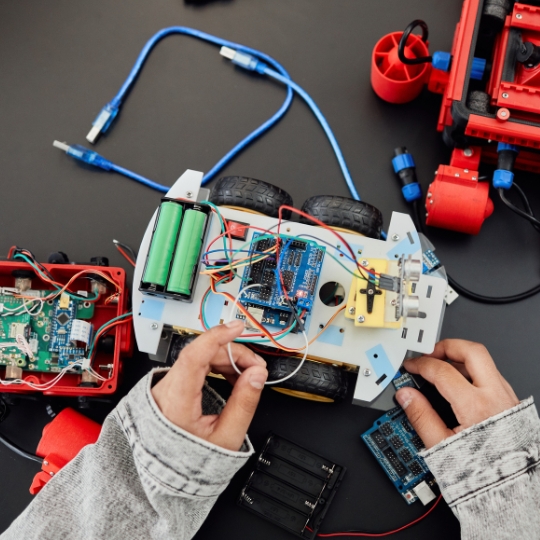

At its core, the robotics definition describes the study and application of robots that perform tasks traditionally handled by humans. This field combines mechanical engineering, electrical engineering, and computer science to create robots that sense, act, and adapt to their environment. These robots tackle tasks ranging from simple manual work to complex decision-making operations.

Key Components of Robotics | Breaking Down the Robotics Definition

Automation

A key part of the robotics definition is automation. Robots handle repetitive or complex tasks with high efficiency, reducing human involvement in hazardous or tedious work.

Precision and Repeatability

Robots excel in precision. They perform tasks with extreme accuracy, consistently surpassing human capabilities in consistency and repeatability, which ensures high-quality production outcomes.

Flexibility and Adaptability

Modern robots demonstrate flexibility, despite the robotics definition suggesting rigid functionality. They adapt to various tasks through reprogramming, making them valuable across industries.

Safety

Robots significantly enhance workplace safety. The robotics definition includes systems that protect workers, especially in dangerous environments like construction sites or chemical plants.

Types of Robots | Exploring the Robotics Definition in Action

Industrial Robots

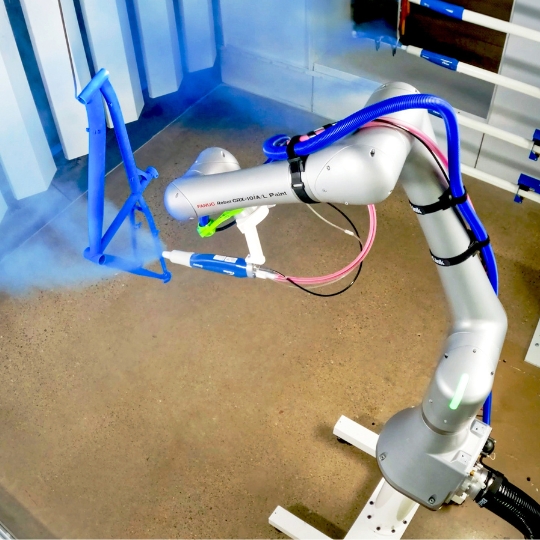

Industrial robots automate tasks such as welding, painting, assembly, and material handling, delivering speed and accuracy on production lines.

Collaborative Robots (Cobots)

Cobots redefine how humans work with machines. Unlike traditional robots, cobots collaborate with human operators to improve safety and efficiency, operating seamlessly in shared spaces.

Service Robots

Service robots bring robots into non-industrial settings, assisting in hospitals, restaurants, and homes. They clean, deliver medications, and perform other helpful tasks.

Autonomous Robots

Autonomous robots operate independently. Using sophisticated sensors and artificial intelligence (AI), they navigate and adapt to dynamic environments, such as autonomous vehicles or drones.

The Importance of Robotics in Manufacturing | A Deeper Dive into the Robotics Definition

Robotics plays a transformative role in manufacturing. Robots improve productivity, precision, and safety by automating tasks like welding, assembly, and painting. They keep production lines running smoothly and minimise errors.

How Robotics Enhances Workplace Efficiency

Robots elevate workplace efficiency. They take over repetitive, physically demanding, or hazardous tasks, allowing human workers to focus on complex, value-added activities. This shift boosts productivity and creates safer work environments.

Applications of Robotics | Real-World Uses

Robotics spans numerous industries, including manufacturing, healthcare, and logistics. Key applications include:

Material Handling: Robots efficiently handle, move, and store materials, reducing human effort and speeding up processes.

Welding and Assembly: Robots ensure precise welds and faster assembly processes, particularly in the automotive sector.

Logistics: Robots optimise inventory management, package sorting, and product delivery, cutting operational costs and boosting efficiency.

The Future of Robotics | Robotics Definition

In conclusion, the robotics definition covers everything from industrial machines to advanced cobots and autonomous systems. Rapid advancements in robotics technology continue to reshape industries, enabling businesses to boost productivity, improve safety, and reduce costs.

At Automated Solutions Australia, we help businesses leverage robotics to optimise their operations. Whether you need industrial robots, collaborative robots, our bespoke automation solutions will help to transform your operations, while our team of experts guide you every step of the way.

Contact us today to discover how robotics can transform your operations.

📞 1800 ROBOTS

📧 [email protected]

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Materials Handling Robots |

More (Recent) News Stories from Automation Solutions Australia:

Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers |Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry | Automatic Systems | Automated Manufacturing System | Auto Robots | Automatic Material Handling | Picking Robots | CNC Machinery Solutions | Australia Wide Automation | Automatic Coating | Collaborative Robots in Manufacturing | Automatic Solutions | Automated Robot | Robotics Integrators | Robotic Solutions | PLC Industrial Automation | Automated Materials Handling | Robots Used in Industry | Cobot Integration | Palletisers | Robotic Spot Welding | Industrial Robots for Sale | Robots in Business | Collaborative Welding Robots | Robot Solution | Adelaide Automation | Shot Blasting Services | Cobots and Robots | Industrial Robotics Companies | Industrial Welding Robots | Automatic Blasting Machine | CRX | Robotics and Manufacturing |