Understanding Fibreglass Coating and Fibreglass Gel Coat | What You Need to Know

When it comes to creating durable and attractive surfaces, fibreglass coating and fibreglass gel coat play crucial roles. Various industries, from automotive to marine, widely use these materials.This is because they provide a strong, protective finish. Thus enhancing both the appearance and longevity of fibreglass products.

What is Fibreglass Coating?

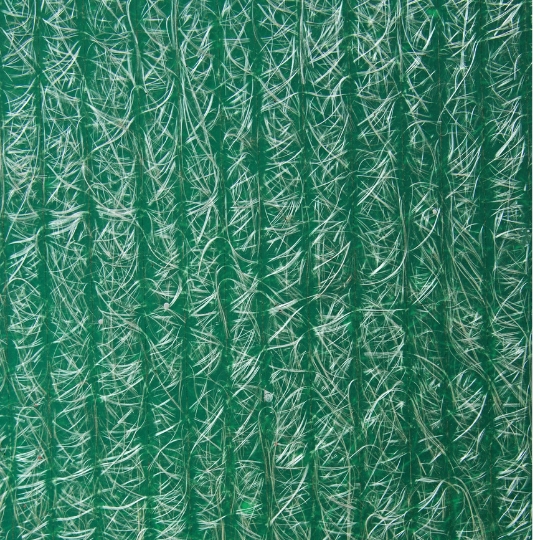

Fibreglass coating involves applying a protective layer to fibreglass surfaces. This shields from environmental damage, such as UV rays, moisture, and chemicals. This not only preserves the integrity of the fibreglass but also adds a smooth, glossy finish. It is therefore both aesthetically pleasing and functional. If you work in industries where durability and appearance are key, understanding the importance of fibreglass coating is essential.

What is Fibreglass Gel Coat?

On the other hand, fibreglass gel coat is a specialised form of coating applied directly to the mould surface before the fibreglass itself is laid. This creates a high-quality, protective outer layer that forms the visible surface of the product. Additionally, it is known for its exceptional resistance to water, chemicals, and impact. Therefore making it a popular choice for applications such as boat hulls, water tanks, and automotive panels.

The Importance of Accurate Application

Both fibreglass coating and fibreglass gel coat require precise application to ensure optimal performance. Improper application can lead to defects, such as blistering, cracking, or a weak bond between the coating and the fibreglass substrate. Therefore, using the right techniques and tools is crucial to achieving a flawless finish that will stand the test of time.

Robotic Application of Fibreglass Coating and Gel Coat with FANUC Robots

In today’s fast-paced industrial environment, automation is key to maintaining consistency and efficiency. This is where FANUC robots come into play. For those involved in applying fibreglass coating and fibreglass gel coat, integrating FANUC robots into your process can revolutionise your operations.

FANUC robots are designed for precision and consistency, ensuring that each application is flawless. Whether you’re coating large surfaces or intricate parts, these robots can handle the task with ease, reducing waste and improving productivity. By automating the application process, you can achieve a higher level of quality control while also reducing the risk of human error.

At Automated Solutions Australia (ASA), we specialise in integrating FANUC robots into various industrial processes, including the application of fibreglass coating and fibreglass gel coat. With over 20 years of experience, we help businesses like yours harness the power of automation to achieve superior results.

Ready to Elevate Your Coating Process with ASA?

If you’re looking to enhance your applications, consider the benefits of automation. Contact ASA today to learn more about how FANUC robots can take your production to the next level.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Hnadling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers | Automation Robotics |