At just 22 years old, Alex Jackson is already making significant strides in the world of robotic automation. As a Mechatronics graduate working full time at Automated Solutions Australia (ASA) in Melbourne, Alex is part of a team that designs, assembles, installs, and commissions robotic solutions across Australia and New Zealand. His journey is one of passion, determination, and an unwavering commitment to quality.

When asked about his role at ASA, Alex describes it as incredibly fulfilling. “The process of translating designs that I made into reality, into a customer’s site where everything works smoothly, is something that is never going to get old for me,” he shares. This satisfaction drives Alex to overcome challenges, no matter how daunting they may seem.

A typical day for Alex is a balance of hands on work in the workshop and design tasks. He’s responsible for everything from wiring connectors and assembling grippers to creating electrical drawings and programming HMI systems. His work is varied, and each project brings its own set of challenges and rewards.

One of the most exciting projects Alex has been involved in, was a recent automated welding cell. The project features a seven meter long, three-axis positioner for parts to be welded by FANUC’s ARC Mate 120iD. The sheer scale and complexity of this project are what make it particularly thrilling for Alex.

Throughout his time at ASA, Alex has encountered many unique challenges, including a control system overhaul for Australian Wool. This project required tearing out and reinstalling an entirely new system into an old automatic wool cut and grab machine. “The combined many years of experience of my mentors were crucial in overcoming this challenge,” Alex notes.

The impact of ASA’s work on clients is profound. Alex has witnessed firsthand the difference that automated machine tending cells can make in productivity. He recalls visiting multiple customer sites and seeing the satisfaction of operators who can now let the robots handle the heavy lifting, allowing them to focus on other tasks.

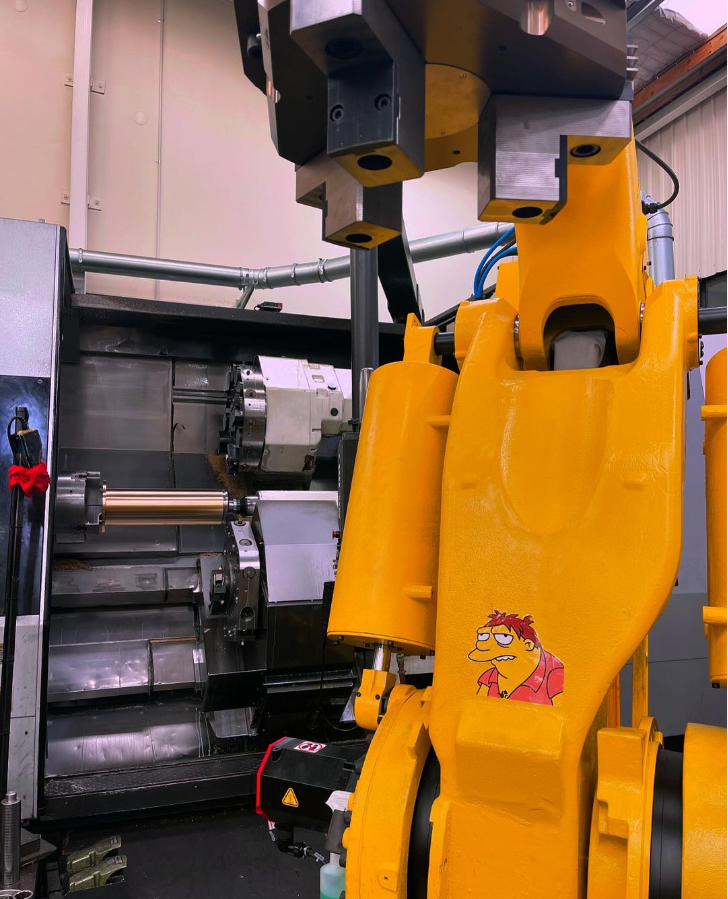

One of Alex’s proudest moments was the successful installation and commissioning of a second machine tending cell for Inflatable Packers International. Despite initial challenges, the cell has been operational for months with minimal issues, leading to increased production and a very satisfied client.

Looking ahead, Alex is excited about the future of robotic automation, particularly the advancements in Artificial Intelligence. He believes ASA will continue to lead the way, leveraging over 20 years of experience to integrate new technologies into their solutions.

The culture at ASA Melbourne is another aspect that Alex deeply appreciates. “The company culture at ASA Melbourne is very friendly and teamwork oriented,” he says. The collaborative environment makes him feel valued and part of a team working together towards common goals.

When asked about his favourite robot model, Alex mentions the M900iB/700 installed at AW Fraser in New Zealand. The sheer size and power of the robot, nicknamed ‘Barney,’ left him in awe. “Being able to throw around 500 kilograms of bronze like it’s nothing is very appealing to me,” he says with a smile.

Outside of work, Alex’s love for computers continues to influence his career. Having built PCs since he was a teenager, he sees his work in designing and building system control cabinets as an evolution of that passion.

For those interested in pursuing a career in robotic automation, Alex offers this advice: “Get involved at any level, whether that be through robotic clubs at school, internships and mentoring with automation companies, or your own side projects. A baseline of experience in the field makes you a much more attractive candidate to businesses and will propel you into your chosen career.”

Alex Jackson’s story is a testament to the power of passion, persistence, and teamwork. As he continues to innovate and grow at ASA, there’s no doubt that the future of robotic automation is in capable hands.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Hnadling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers |