The Cobot | Transforming the Future of Collaborative Robotics in Industry

The term cobot, or collaborative robot, refers to robots specifically designed to work safely alongside humans in various industries. The concept of cobots first emerged in the 1990s. It was born out of a need for robots that could perform repetitive or complex tasks while maintaining human interaction. Unlike traditional industrial robots that require fenes or barriers for safety, cobots integrate seamlessly with human workflows. Over the years, advancements in sensors, control systems, and AI have made the cobot more flexible. In addition has become more intuitive, and safe, opening up a new era of collaboration between people and machines.

Applications of the Cobot Across Industries

Today, the cobot is used in an impressive range of applications across industries. Cobots excel in tasks that demand precision, consistency, and flexibility, such as assembly, packaging, quality inspection, and material handling. In manufacturing, it can handle repetitive tasks with ease, allowing human workers to focus on creative and strategic work. With capabilities that can be programmed and adjusted on demand, the cobot adapts quickly to changing tasks, making it ideal for industries with diverse production needs.

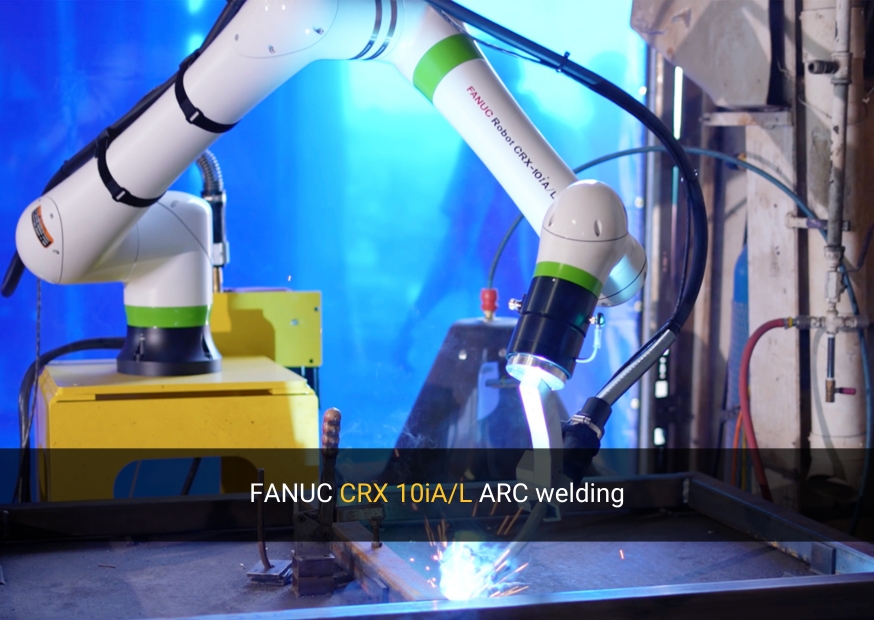

The FANUC Cobot Range: Versatility and Reliability

FANUC, a leader in automation technology, offers an advanced range of cobots designed to handle a variety of industrial applications. FANUC’s cobot lineup combines the company’s expertise in robotics with cutting-edge collaborative safety features, allowing the cobot to work closely with humans without sacrificing productivity. With models that range in payload and reach, FANUC cobots are versatile enough to handle intricate tasks like precision assembly while strong enough to lift and move heavy materials. Equipped with intuitive control systems, they are easy to program, making them a top choice for businesses looking to optimise production efficiency.

ASA’s 20+ Years of Experience with FANUC

At Automated Solutions Australia (ASA), we’re proud to bring the power of FANUC cobots to our clients. With over 20 years of experience in integrating FANUC robots, ASA has the expertise to tailor cobot solutions to meet each client’s unique needs. From initial design and programming to installation and ongoing support, ASA provides a full-service approach to cobot integration. Our team’s extensive knowledge of FANUC’s technology ensures they operate seamlessly within its production environment, delivering maximum productivity and flexibility.

Customised Cobot Solutions for Every Industry

Moreover, at ASA, we understand that each industry has specific requirements when it comes to cobot applications. Our team works closely with clients to design FANUC cobot systems. These align perfectly with their operational goals, whether it’s in automotive, aerospace, healthcare, or manufacturing. By choosing ASA for your cobot integration, you’re partnering with an experienced team that’s committed to delivering reliable and effective automation solutions.

Unlock the Benefits of Robotic Integration with ASA

If your business is ready to embrace the benefits of cobots, reach out to ASA. With our proven expertise and FANUC’s industry-leading cobots, we can help you achieve new levels of efficiency, safety, and productivity. Let’s bring the power of collaborative robotics to your operations today.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Materials Handling Robots |

More (Recent) News Stories from Automation Solutions Australia:

Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia |Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers |Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry | Automatic Systems | Automated Manufacturing System | Auto Robots | Automatic Material Handling | Picking Robots | CNC Machinery Solutions | Australia Wide Automation | Automatic Coating | Collaborative Robots in Manufacturing | Automatic Solutions | Automated Robot | Robotics Integrators | Robotic Solutions | PLC Industrial Automation | Automated Materials Handling | Robots Used in Industry |