Picking and Packaging for Maximum Efficiency in Warehouses

Warehouse picking and packaging are crucial processes in fulfilling customer orders. Therefore this process significantly affects the time an order spends in a warehouse. With a large volume of warehouse operating costs attributed to order picking, improving these processes is vital for boosting productivity and overall customer satisfaction.

The Importance of Picking and Packaging | Lowering Costs and Improving Accuracy

Picking involves selecting products from inventory while packing prepares these items for shipment. Efficient picking and packing processes lower costs, improve accuracy, and accelerate order fulfillment. Therefore it is crucial for exceeding customer expectations and ensuring a seamless experience. So this not only enhances your business’s efficiency but also boosts customer satisfaction and loyalty, driving growth and success.

Picking and Packaging Process

Order Receiving: The system generates a packing slip when an order comes through.

Order Picking: Warehouse order picking may involves retrieving items from your inventory to fulfill customer orders, essentially selecting the products that need to be shipped. Therefore this process can be performed manually, with workers navigating the shelves to pick items, or with the assistance of automated systems like conveyor belts or robots. Thus manual picking is often the most time-consuming and labor-intensive aspect of warehouse operations.

Order Packing: Items are packed, labelled, and prepared for shipping, ensuring they are protected and correctly labeled.

Order Shipping: Packages are consolidated and shipped to customers,

Picking and Packaging | Enhancing Efficiency with Automation

Have you considered drastically improving and streamlining your picking and packaging process with automation and advanced technologies? Automated picking systems, such as robots and conveyor belts, minimise human error and increase speed. Additionally, these systems are crucial in meeting the growing demand for rapid online shopping, including same-day delivery.

Automated Picking and Packaging

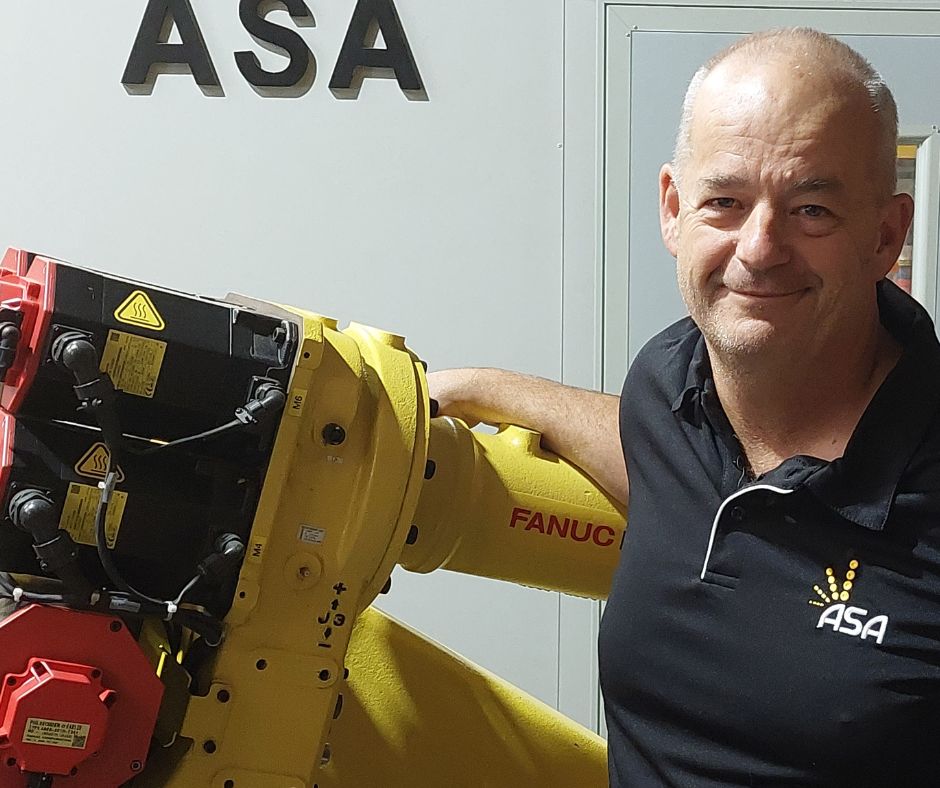

Automated Solutions Australia (ASA) specialise in integrating FANUC robots for various applications including automated picking and packinging. These robots offer numerous benefits:

Increased Productivity: Robots perform tasks faster and more accurately than humans.

Improved Quality: High precision and consistency reduce defects and enhance customer satisfaction.

Enhanced Safety: Robots handle dangerous tasks, reducing the risk of injury to human workers.

Cost Savings: Automation reduces labor costs and minimises errors.

Increased Flexibility: You can reprogram FANUC robots for different tasks, allowing them to adapt quickly to market demands.

Picking and Packaging Software

FANUC has developed specialised software for managing multiple robots, specifically designed for picking and packaging operations. This innovation enhances productivity and simplifies the adoption process, offering significant cost savings compared to manual labor and accelerating production times.

FANUC’s fully customisable iRPickTool software allows for easy adjustment of your robots to fit any unique pick and pack production scenario. Whether you have varying numbers of conveyors, cells, goods, package designs, or line setups, this software ensures seamless integration and optimal performance.

Why Choose ASA for Your Automation Needs?

With over 20 years of experience, ASA is a leader in integrating FANUC robots for a variety of applications across a variety of industries. Our expertise ensures that businesses achieve their automation goals, improving efficiency and competitiveness. Ready to transform your warehouse operations? Contact ASA today at 1800-ROBOTS or email us at sales@automatedsolutions.com.au to learn more about our advanced solutions.

Embrace the future of business and stay ahead in a rapidly changing market.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging Robots| Material Removal Robots | Shot Blasting and Peening |

More Recent News Stories from ASA:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Automation and Robotics | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Hnadling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Robotics in Business | Laser Welding- What is it? |