In the rapidly advancing world of manufacturing, various types of welding robots are becoming indispensable tools for companies. Thus aiming to enhance efficiency, precision, and productivity. These types of welding robots are specifically designed to meet diverse welding needs across industries. Including automotive, aerospace, electronics, and more. As we explore the different types of welding robots, it’s clear that each offers unique advantages tailored to specific applications.

The Critical Role of Seam Tracking Welding in Robotic Welding

One of the advancements in welding automation is seam tracking welding. This innovative technology allows welding robots to precisely follow the weld seam, ensuring consistent and high-quality welds every time. With seam tracking welding, robots can adjust in real-time to variations in the workpiece. Therefore making it particularly valuable in complex welding tasks. As manufacturers continue to adopt various types of welding robots, the inclusion of seam tracking welding is proving to be a game-changer in achieving superior weld quality.

Key Advantages of Robotic Welding

When considering the integration of robotic systems, it’s essential to understand the numerous advantages of robotic welding. These advantages include:

Consistent Weld Quality: Across all types of welding robots, consistency is a major benefit. Robotic welding ensures uniform welds, which greatly reduces the likelihood of defects and improves overall product quality.

Increased Production Speed: Another one of the key advantages of robotic welding is the significant boost in productivity. Welding robots can work continuously and at higher speeds than human welders, making them crucial in high-demand production environments.

Cost Efficiency: A key advantage across all types of welding robots is the reduction in manual labor costs and waste. By automating the welding process, companies can lower overall production costs while maintaining high quality.

Enhanced Accuracy with Seam Tracking Welding: With seam tracking welding, robotic systems achieve unparalleled precision. This accuracy is one of the standout advantages of robotic welding, especially when working with delicate or complex components.

Exploring the Different Types/Applications of Welding Robots

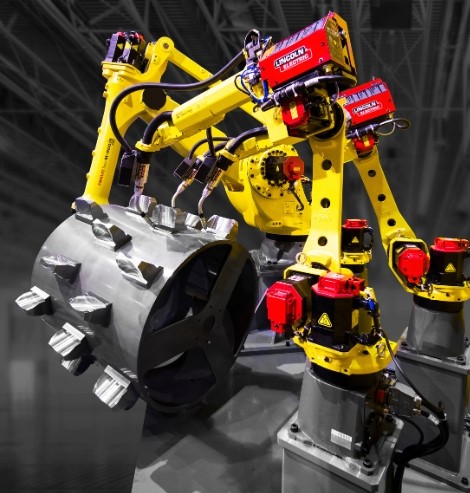

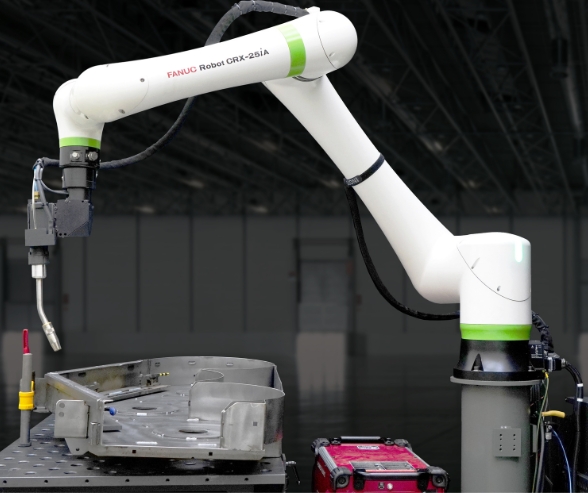

Arc Welding Robots: These types of welding robots are ideal for tasks requiring high precision, such as joining metals in intricate shapes. The precision and control offered by arc welding robots are enhanced when combined with seam tracking welding technology.

Spot Welding Robots: Spot welding robots are known for their speed and efficiency. This makes them perfect for high-volume production environments, such as automotive manufacturing. Among the different types of welding robots, spot welding robots stand out for their ability to perform rapid welds while maintaining quality.

Laser Welding Robots: When precision is paramount, especially in industries like electronics and medical device manufacturing, laser welding robots come into play. These types of welding robots are particularly effective in applications requiring minimal heat distortion.

Why Choose Automated Solutions Australia (ASA) for Your Welding Automation Needs?

As you consider integrating various types of welding robots into your production line, it’s crucial to work with experts who understand the complexities of these technologies. At Automated Solutions Australia (ASA), we specialise in integrating welding robots from FANUC, a global leader in robotic automation. With our deep expertise and FANUC’s cutting-edge technology, we can help you choose the right types of welding robots for your specific needs.

Whether you’re looking to implement seam tracking welding or want to explore the full range of advantages of robotic welding, ASA is your go-to partner. We’re here to support you from concept to implementation, ensuring that your manufacturing process is optimised for success.

Contact us today to learn more about how the different types of welding robots and seam tracking welding can transform your production line with the many advantages of robotic welding.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

| Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Automation and Robotics | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Robotics in Business | Laser Welding | Picking and Packaging | Grit Blasting Explained | Robotic Lathe and Milling | Robotic Integration | Programmable Logic Controllers | Robotic Mig Welding | Robotic Dispensing | Robotics and Automation Engineering | Automation Companies Aus | Robotics Companies | Robotics Industry Aus | Robots and Machines | CNC Machine Adelaide | Automotive Robots |