Robotic integration is transforming industries by enhancing efficiency, precision, and productivity. This guide will walk you through the essentials of robotic integration. This includes its benefits, and how it can transform your business operations.

What is Robotic Integration?

Robotic integration involves incorporating robots into existing manufacturing and production systems to automate tasks. This process includes the setup, programming, and optimisation of robotic systems. This is to ensure they work seamlessly with other machinery and software in your production line. The purpose of robotic integration is to streamline operations, reduce human error, and increase overall efficiency.

Key Benefits of Robotic Integration

Increased Productivity: Robotic integration allows for continuous operation without breaks, significantly boosting production rates and throughput.

Enhanced Precision and Consistency: Robots perform repetitive tasks with high precision, ensuring uniformity and significantly reducing the likelihood of errors.

Improved Safety: By automating dangerous or repetitive tasks, robotic integration reduces the risk of workplace injuries and enhances overall safety.

Cost Savings: The initial investment in robotic integration can seem expensive. However, the long-term savings from reduced labour costs, increased productivity, and fewer errors can be significant.

Flexibility and Scalability: Robots can be reprogrammed and adapted to perform various tasks. Thus making them highly flexible and scalable to meet changing production demands.

The Robotic Integration Process

Needs Analysis: The first step in robotic integration is a thorough assessment of your current processes and identification of areas that can benefit from automation. A Needs Analysis identifies bottlenecks. This includes constraints in batch processing, issues with environmental compliance, manufacturing flexibility limitations, and areas where material usage can be optimised, to name a few.

Design, Concepting and Simulation: This determines robot configurations and cycle times before a robot cell is purchased or put into production, providing clients with a clear view of the impact on their manufacturing capabilities. By using tools like ROBCAD and ROBOGUIDE, clients can visualise end results, estimate cycle times, and identify any spatial or mechanical constraints, ensuring seamless integration into their production environment.

Installation and Setup: Robotoic Integrators install, configure, and test the robotic systems to ensure they function correctly and meet the desired performance criteria.

Programming and Optimisation: Robotic Integrators program the robots to perform the required tasks and optimise the system for maximum efficiency and productivity.

Training and Support: Employees are trained to operate and maintain the robotic systems, and ongoing support is provided to ensure the system continues to perform optimally.

Applications of Robotic Integration

Robotic integration is utlisable by various industries, including:

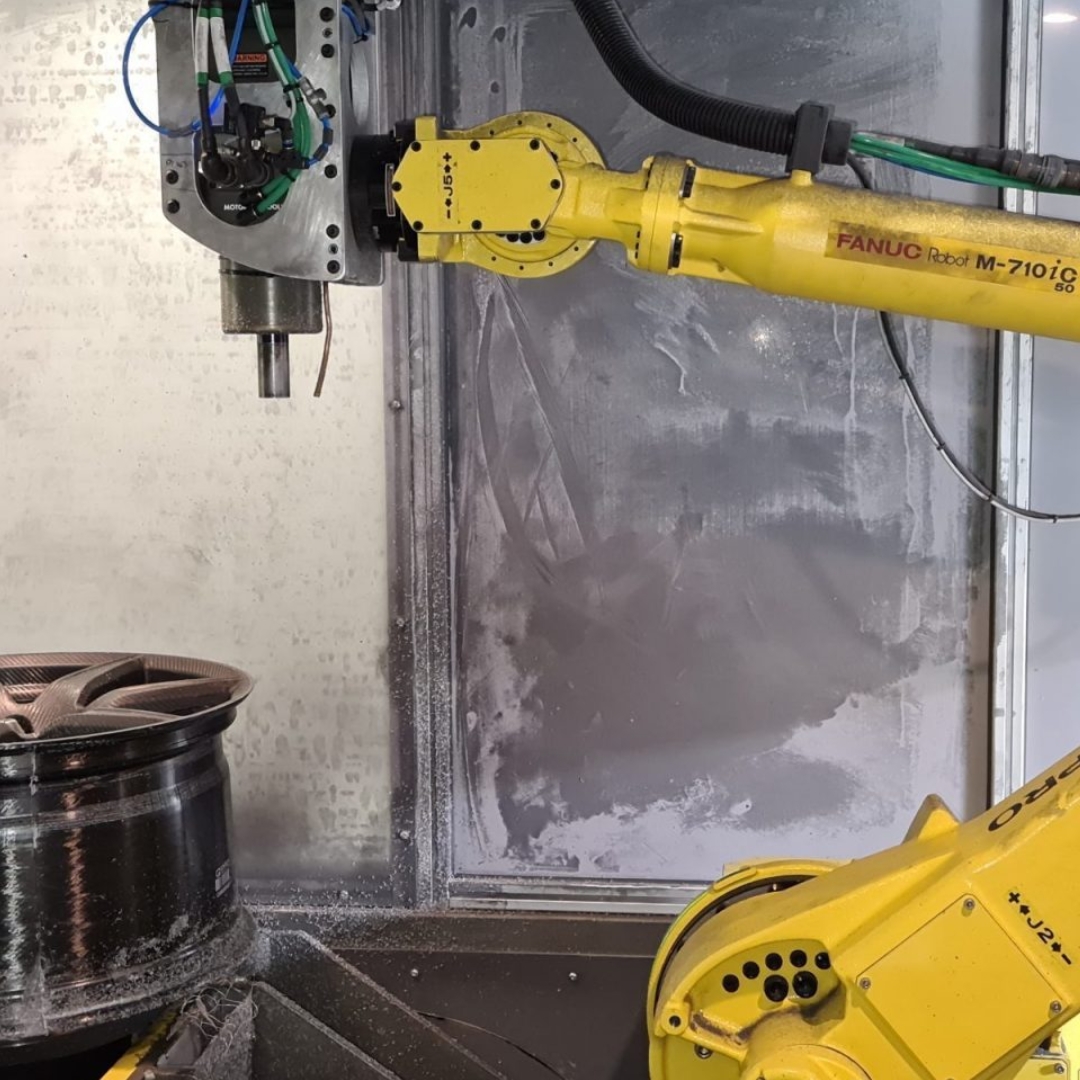

Automotive: Assembly, welding, painting, and inspection.

Electronics: Component assembly, testing, and packaging.

Food and Beverage: Sorting, packaging, and palletizing.

Medical: Dispensing, packaging, and quality control.

Manufacturing: Material handling, machining, machine tool tending, and paint finishing.

Robotic Integration at Automated Solutions Australia (ASA)

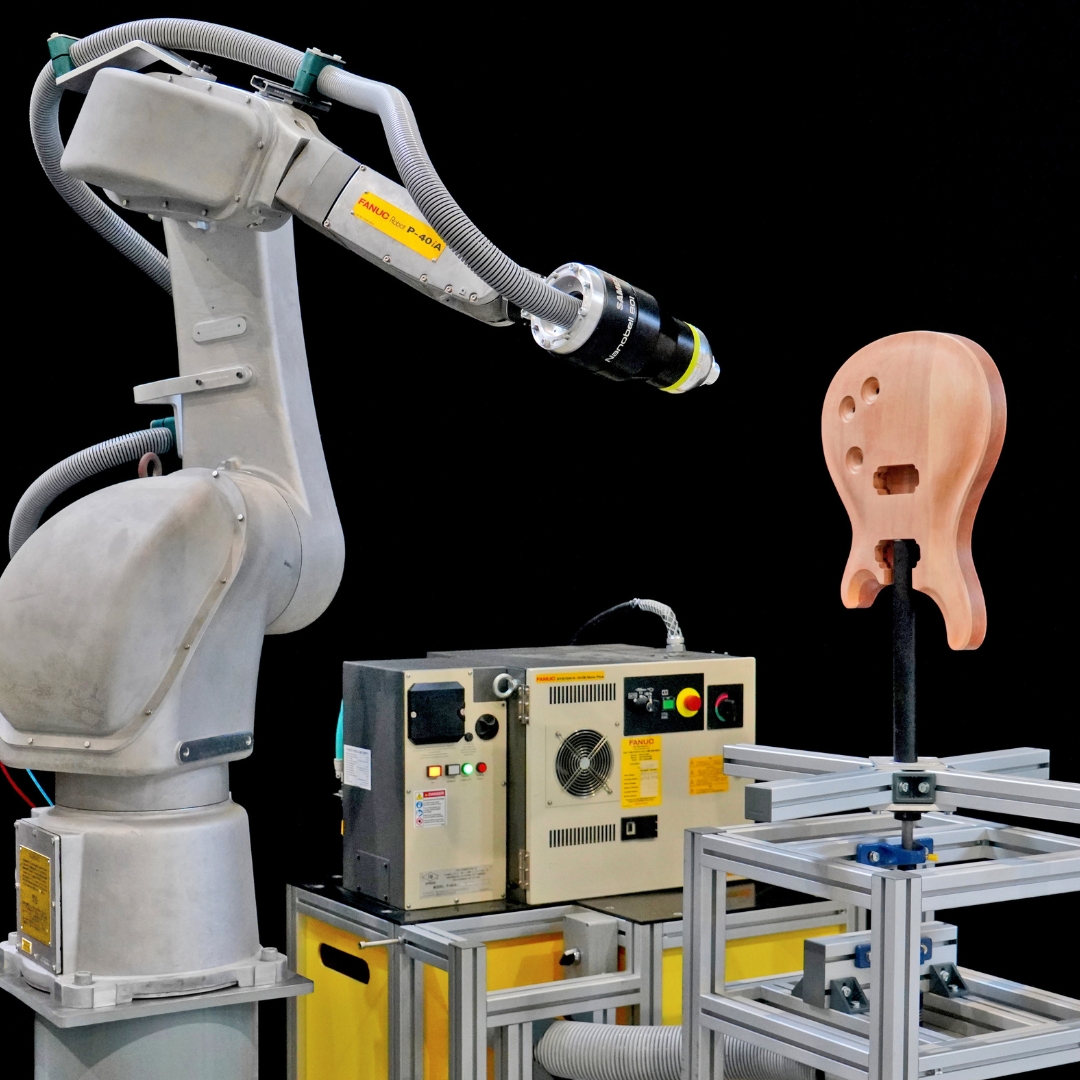

At Automated Solutions Australia (ASA), we specialise in robotic integration, helping businesses achieve their automation goals across the globe. We integrate FANUC robots, renowned for their reliability and performance, into your production processes. Our expertise ensures that your robotic integration is seamless, efficient, and tailored to your specific needs.

Contact ASA today to learn more about how our robotic integration solutions can transform your business and propel you towards a more automated and efficient future. For all robotic system integration enquiries, please email [email protected] or phone us on 1800 ROBOTS

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging Robots| Material Removal Robots | Shot Blasting and Peening |

More Recent News Stories from ASA:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Automation and Robotics | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Robotics in Business | Laser Welding | Picking and Packaging | Grit Blasting Explained | Robotic Lathe and Milling |