What is Spot Welding?

Spot welding is a welding technique that joins two or more metal sheets together. Pressure and heat are applied to specific points. This method works by using an electrical current to create heat between two metal surfaces. Thus melting them enough to fuse together. It’s common in industries such as automotive manufacturing, where speed, strength, and efficiency are key.

In spot welding, two electrodes clamp the metal sheets and apply pressure. All while a strong electrical current passes through the electrodes to heat the area between them. As a result, the heat melts the metal, forming a solid weld when cooled. This process is typically for materials like steel and aluminum, offering high durability and strength in the weld joints.

What is Spot Welding? | How Does Spot Welding Work?

Spot welding is efficient and simple. First, you place the metal sheets between the two copper electrodes. When the electrodes apply pressure, they send an electrical current through the metal surfaces. So this causes the heat necessary to melt the material. After the metal cools, the sheets are firmly welded together, forming a strong bond.

This method is fast and allows manufacturers to create consistent, high-quality welds without the need for additional materials, such as welding rods or filler metals. Additionally, spot welding requires minimal prep work, making it an ideal choice for industries that focus on high-volume production.

What is Spot Welding? | Versatility and Efficiency

Spot welding offers several advantages. It is cost-effective and highly efficient, making it ideal for mass production. You will often see it used in the automotive industry, where the technique quickly joins sheet metal parts to create car bodies. This method of welding is also environmentally friendly as it requires minimal material and energy to achieve durable welds.

Additionally, spot welding is versatile. It can be used for different materials, including both thin and thicker metal sheets, and is excellent for producing large volumes of welded parts without compromising on quality.

What is Spot Welding? | Robotic Spot Welding – Taking Precision to the Next Level

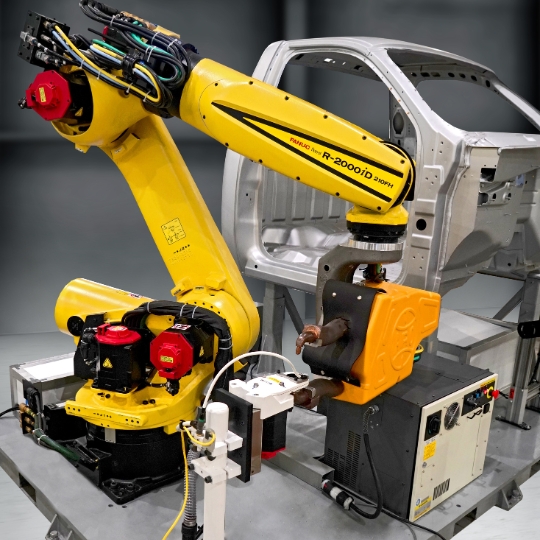

In modern industries, robotic spot welding is becoming increasingly popular. Automation takes the efficiency of spot welding to new heights by improving precision and consistency. By integrating robots into the process, manufacturers can ensure that each weld is uniform, reducing the chance of errors and improving product quality.

Robots are designed to handle repetitive tasks like spot welding with accuracy and speed. Thus allowing businesses to boost productivity while lowering their labor costs. Moreover, robotic spot welding reduces the risk of human error all whilst enhancing workplace safety, especially in environments where high heat and heavy machinery are involved.

What is Spot Welding? | How ASA and FANUC Robots Can Enhance Spot Welding Efficiency

At Automated Solutions Australia (ASA), we integrate FANUC robots for spot welding, which are in our expert opinion, the best in the business! These advanced robots offer unmatched precision and consistency, enabling manufacturers to achieve high-quality results every time. FANUC robots can handle the rigorous demands of spot welding while also ensuring safety and reliability. Whether you’re working in automotive, aerospace, or general manufacturing, our team can create a bespoke solution that meets your specific needs.

With over 20 years of experience, ASA helps businesses streamline their production processes and stay competitive by integrating the latest robotic welding technologies.

Contact ASA today to learn how FANUC robots can transform your operations!

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

| Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Automation and Robotics | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Robotics in Business | Laser Welding | Picking and Packaging | Grit Blasting Explained | Robotic Lathe and Milling | Robotic Integration | Programmable Logic Controllers | Robotic Mig Welding | Robotic Dispensing | Robotics and Automation Engineering | Automation Companies Aus | Robotics Companies | Robotics Industry Aus | Robots and Machines | Industrial Automation Industry | Fibreglass Coating | Automation Robotics |