The Rise of Collaborative Robots in Manufacturing

In recent years, collaborative robots have gained significant traction in the manufacturing sector, revolutionising how companies approach automation. Unlike traditional industrial robots, which often operate in isolation, collaborative robots (or cobots) are designed to work alongside human workers safely and efficiently. This innovative approach enables manufacturers to streamline processes, enhance productivity, and improve overall operational flexibility.

Enhancing Efficiency and Safety

One of the primary advantages of collaborative robots in manufacturing is their ability to enhance efficiency while prioritising safety. Additionally, advanced sensors and intelligent algorithms equip cobots to detect human presence and adjust their movements accordingly. This means they can work alongside operators without the need for safety fencing. Thus significantly reducing the physical footprint of manufacturing systems. As a result, businesses can optimise their workspace and improve workflow efficiency.

Versatility in Robotic Applications

Furthermore, collaborative robots in manufacturing settings are incredibly versatile, making them suitable for a wide range of manufacturing applications. From assembly and packaging to material handling and quality control, cobots can adapt to various tasks with ease. This flexibility is particularly beneficial for manufacturers dealing with small-batch production or customisation, where traditional automation systems might struggle. Manufacturers can quickly reprogram or redeploy cobots to accommodate changing production needs, thereby supporting agile manufacturing processes.

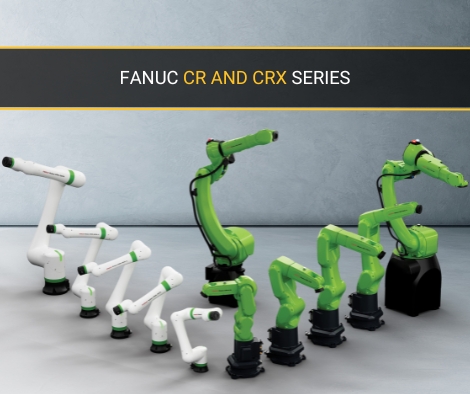

FANUC Collaborative Robots: The Leading Choice

When it comes to collaborative robots for manufacturing, FANUC stands out as a leader in the industry. Known for their reliability and innovation, FANUC’s collaborative robots offer a broad range of payloads and reach options. Therefore making them ideal for diverse manufacturing environments. Engineers design FANUC cobots to handle tasks ranging from simple pick-and-place operations to complex assembly processes, ensuring they deliver consistent performance and precision.

Automated Solutions Australia: Your Ideal Integration Partner

At Automated Solutions Australia (ASA), we integrate FANUC collaborative robots into manufacturing operations. With over 20 years of experience, our team of experts works closely with clients to understand their unique requirements and develop tailored bespoke solutions. We ensure that the integration process is seamless, from initial concept design to installation and ongoing support.

The Future of Manufacturing with Collaborative Robots

As the manufacturing landscape continues to evolve, the adoption of collaborative robots will undoubtedly play a pivotal role in shaping its future. By incorporating FANUC cobots into their operations, manufacturers can not only boost productivity but also enhance workplace safety and operational flexibility.At ASA, we actively help businesses leverage the power of automation to stay competitive in today’s dynamic market.

Let’s Get Started

If you’re interested in exploring how collaborative robots in manufacturing can benefit your business, look no further than Automated Solutions Australia. Our team is ready to guide you through the integration of FANUC collaborative robots, ensuring you unlock the full potential of automation. Contact us today to learn more about our solutions and how we can help you enhance your manufacturing processes.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Materials Handling Robots |

More (Recent) News Stories from Automation Solutions Australia:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers | Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry | Automatic Systems | Automated Manufacturing System | Auto Robots | Automatic Material Handling | Picking Robots | CNC Machinery Solutions | Australia Wide Automation | Automatic Coating |