The Future of Manufacturing | Embracing Automated Robots with FANUC Robotics

In today’s fast-paced industrial landscape, automated robots are revolutionising how companies approach production, quality control, and efficiency. These robots, designed to perform tasks autonomously, not only streamline manufacturing but also improve precision, consistency, and safety. Therefore, automated robots, like those offered by FANUC, have become critical assets across various industries, helping businesses remain competitive in a rapidly advancing market. With automation transforming nearly every sector, integrating advanced automated robotics technology has become more accessible and impactful than ever before.

Why Choose FANUC for Automated Robot Solutions?

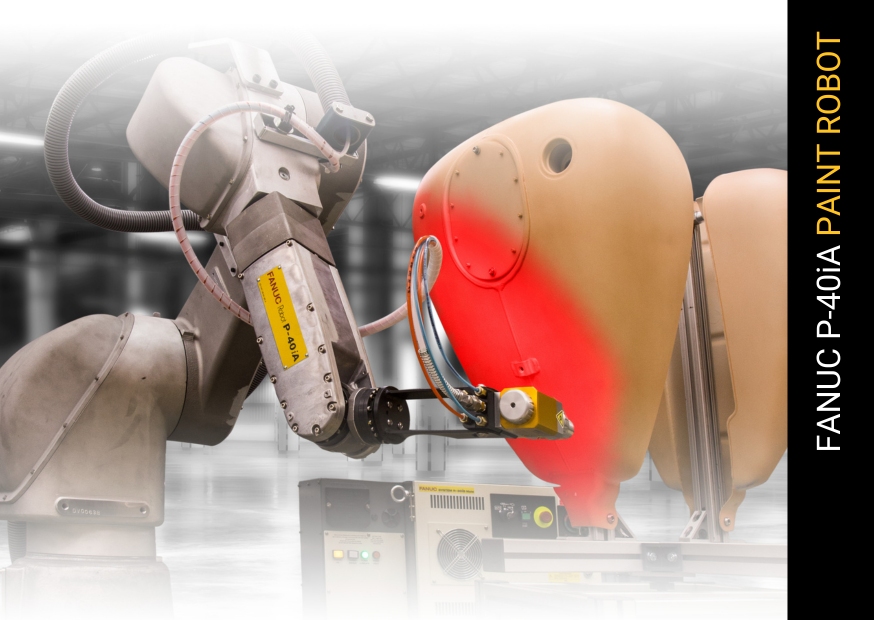

FANUC robots, a trusted name in automation, stand out due to their reliability, versatility, and advanced capabilities. FANUC offers a range of automated robots tailored to perform specific tasks with high efficiency. From simple pick-and-place operations to more complex paint, welding, and machine tending roles, FANUC robots excel in diverse applications. Designed for high performance and durability, these robots operate smoothly even under heavy workloads, making them a preferred choice in the automotive, electronics, manufacturing, and food industries (just to name a few!).

Automated Solutions Australia | 20 Years of FANUC Expertise

At Automated Solutions Australia, we’ve been working with FANUC robots for over over 2 decades, integrating them across a broad range of applications. Our expertise with FANUC spans numerous sectors, enabling us to design and implement robotics solutions that cater to each client’s unique operational needs. Whether it’s material handling, welding, painting, machine tending, packaging, or palletising, we provide solutions that maximise efficiency and precision. Over two decades of experience have taught us that no two automation needs are the same, and our tailored, bespoke solution approach, aims to achieve optimal outcomes for every client.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Materials Handling Robots |

More (Recent) News Stories from Automation Solutions Australia:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia |Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers |Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry | Automatic Systems | Automated Manufacturing System | Auto Robots | Automatic Material Handling | Picking Robots | CNC Machinery Solutions | Australia Wide Automation | Automatic Coating | Collaborative Robots in Manufacturing | Automatic Solutions |