In the ever-evolving landscape of the automotive industry, technological advancements have consistently pushed the boundaries of what’s possible. Among these advancements, automotive robots have emerged as a critical component, transforming the way vehicles are manufactured. These sophisticated machines, also known as automotive industry robots, are pivotal in enhancing efficiency. Additionally, they enhance precision and overall productivity in automotive manufacturing processes.

The Rise of Automotive Robots

As we delve deeper into the heart of automotive production, it becomes evident that automotive automation is indispensable. By automating repetitive and labor-intensive tasks, manufacturers can achieve higher levels of consistency and quality in their products. Not only does this automation replace human labor, but it also augments it to perform tasks that require precision and endurance beyond human capabilities. Consequently, the entire production process becomes more streamlined and efficient.

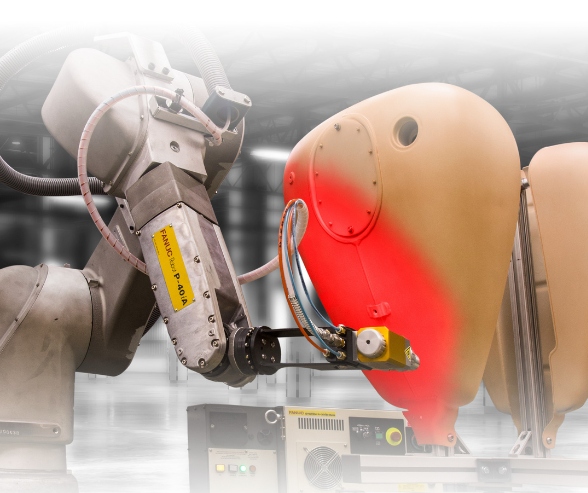

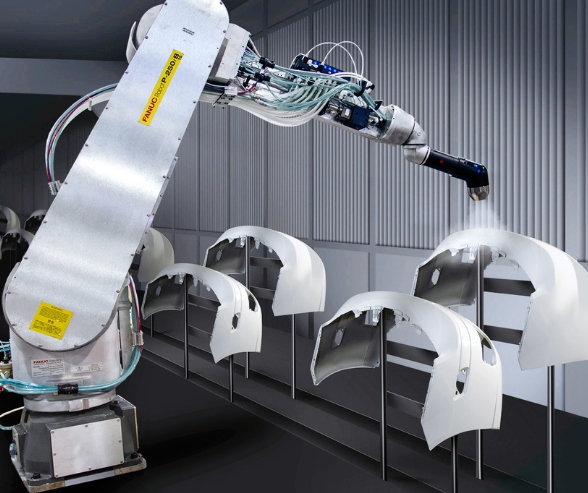

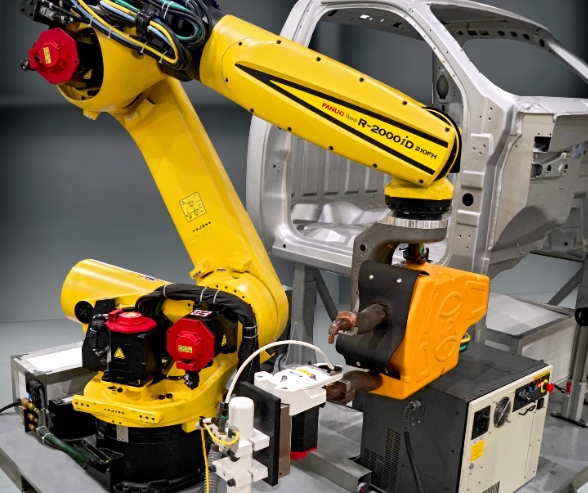

FANUC | The Gold Standard in Automotive Robots

When discussing automotive robots, for us, one name stands out as the gold standard: FANUC. Renowned for their reliability, precision, and innovation, FANUC robots have set the benchmark in the industry. These robots are designed to handle a wide array of tasks, from assembly and welding to painting and inspection. FANUC’s commitment to excellence has made them a preferred choice for automotive manufacturers worldwide.

Automotive Robots | Robotic Integration with Automated Solutions (ASA)

At ASA, we take immense pride in our long-standing partnership with FANUC. For over 20 years, we have been integrating FANUC robots into the automotive industry. Thus helping our clients achieve unprecedented levels of automation and efficiency. Our expertise in implementing these advanced robotic solutions has enabled us to stay at the forefront of automotive automation, delivering results that consistently exceed expectations.

Automotive Robots for the Aftermarket Automotive Industry

Transitioning from traditional manufacturing, it’s important to highlight the impact of automotive robots on the aftermarket automotive industry as well. This sector, which focuses on the production, distribution, and installation of vehicle parts, has greatly benefited from robotic automation. The precision and efficiency of automotive industry robots ensure that aftermarket parts meet the high standards required for performance and safety.

Benefits of Automotive Industry Robots

Increased Productivity: Automotive robots work non stop, around the clock, significantly boosting production rates and reducing downtime.

Enhanced Quality: With precise control over manufacturing processes, these robots ensure that each component is produced to exact specifications, resulting in higher quality end products.

Cost Efficiency: By streamlining operations and reducing the need for manual labor, automotive robots help manufacturers save on operational costs while maintaining high standards of production.

Safety: Robots can perform hazardous tasks, reducing the risk of injury to human workers and creating a safer work environment.

In conclusion, the integration of automotive robots into the manufacturing process is no longer a futuristic concept but a present-day reality that continues to evolve. As the automotive industry advances, so too will the role of automation and robotics. FANUC robots are at the forefront of this evolution, setting the standard for what automotive robots can achieve. At ASA, our commitment to integrating FANUC robots into automotive manufacturing processes ensures that we remain leaders in automotive automation, driving the industry towards a more efficient and innovative future.

For more information on how ASA can help you leverage the power of FANUC automotive robots, contact us today. Let’s drive the future of automotive manufacturing together.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

| Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Automation and Robotics | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Robotics in Business | Laser Welding | Picking and Packaging | Grit Blasting Explained | Robotic Lathe and Milling | Robotic Integration | Programmable Logic Controllers | Robotic Mig Welding | Robotic Dispensing | Robotics and Automation Engineering | Automation Companies Aus | Robotics Companies | Robotics Industry Aus | Robots and Machines | CNC Machine Adelaide |