Laser welding is a precise process of fusing metal parts using a beam of laser light. This advanced technique has found numerous applications across various industries, particularly in the automation of small-component welding. It is most useful in the automotive, aerospace, and electronics sectors, where precision and efficiency are critical. This article will further discuss how it works, the process, types, and advantages.

What is Laser Welding?

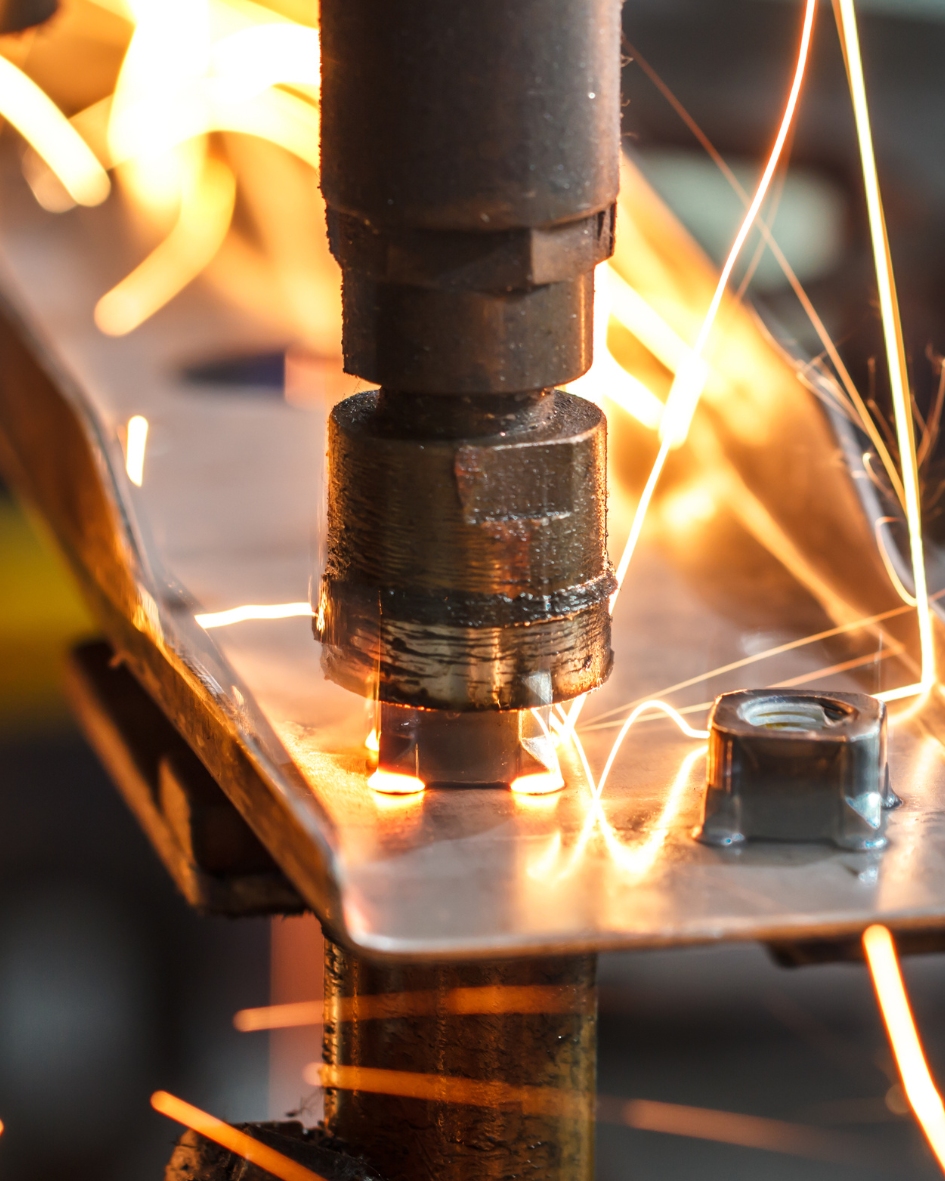

Laser welding is a highly accurate and delicate welding process that uses a focused laser beam to join metal parts. A freestanding laser source generates the laser beam. It’s then directed to a machine-mounted or handheld collimator ‘torch’ and onto the workpiece. So next, the directed energy beam heats and melts the workpieces and the resulting melt pool fuses the targets together, forming a well-integrated weld.

How Does Laser Welding Work?

Laser welding, uses a concentrated heat source in the form of a laser to melt materials, which then fuse as they cool. This versatile process can weld thin materials at rapid speeds and create narrow, deep welds for thicker materials.

Key Advantages of Laser Welding

A key advantage of laser welding is the high precision and close control of applied energy. The energy can be precisely directed to the exact location where the weld is needed with virtually no over-application or spread. Therefore allowing for extremely precise liquefaction with a much smaller heat-affected zone than any other welding method. Thus causing less damage to surrounding areas and reducing bulk heating and associated deformation.

Industries That Utilise Laser Welding

Laser welding is commonly used in several industries:

Automotive: Laser welders can join or construct body panels, engine components, suspension parts, fuel injectors, and sensors.

Aerospace: Laser precision is essential for aircraft engines, landing gear, and other components. As well as in the manufacture of rockets and spacecraft.

Medical: Medical devices such as pacemakers, dental implants, surgical instruments, surgical implants, and prosthetics require detailed welds that laser welding can provide.

Electronics: Small, precise welds are crucial for the manufacture of circuit boards, complex component packages, sensors, smartphones, laptops, and more.

The beam can be generated by solid-state, fiber, or CO2 lasers, each offering specific advantages. At the beam’s focus point, the metal reaches its melting point, forming a localised pool. The laser beam is then moved along the surface of the joint, melting a leading edge and leaving the molten, fused trailing edge to cool and solidify.

Types of Laser Welding

Conduction Welding: Uses lower power density, merging the melted edges by capillary action alone, suitable for thin materials with precisely fitted edges.

Deep Penetration Welding: Suitable for thicker materials, it uses high laser power to heat deep and wide portions of the material, often with a filler rod.

Laser Spot Welding: Best for small, complex parts, creating small, localised welds.

Laser Seam Welding: Creates long, continuous seams, often with a filler rod.

Hybrid: Combines laser welding with other processes like MIG and TIG, offering the advantages of both systems.

Advantages of Laser Welding

Precision: Creates small, intricate welds with high accuracy, minimising the heat-affected zone and reducing distortion and material waste.

Speed: The concentrated energy heats the melt pool quickly. Thus allowing for rapid welding speeds.

Versatility: Can weld a wide range of materials, including metals, plastics, and some ceramics, and join dissimilar materials.

Quality: Results in high-quality welds with consistent mechanical properties and minimal defects.

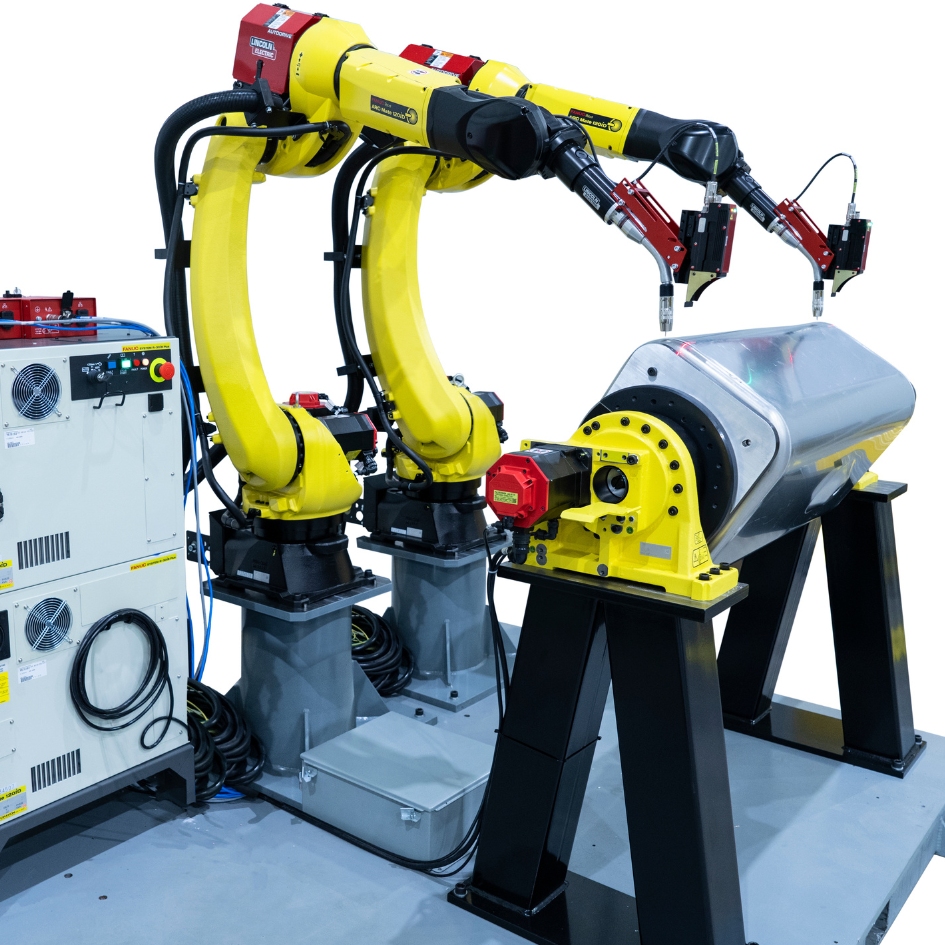

Automation: Easy to automate, delivering high-volume production with consistent quality, essential in industries like automotive, aerospace, and electronics.

Robotic Laser Welding: What Does it Involve?

Robotic laser welding is a high-precision joining process that uses an automated robot with a focused laser beam, making it ideal for many industries. Specifically, at Automated Solutions Australia (ASA), we integrate FANUC robots for laser welding, ensuring you receive the highest quality and efficiency.

Ready to Transform Your Welding Processes?

If you’re looking for an efficient robotic laser welding robot, get in touch with ASA today. Our team of FANUC robot specialists will help you find the perfect robotic laser welding solution for your manufacturing needs. Don’t hesitate to contact us at 1800-ROBOTS or email us at sales@automatedsolutions.com.au.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More Recent News Stories from ASA:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Automation and Robotics | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Hnadling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic LW |