PLC Industrial Automation: Transforming Efficiency and Precision with Advanced Solutions

In the ever-evolving landscape of industrial automation, PLC industrial automation is a vital force, driving efficiency, reliability, and precision across production lines. Programmable Logic Controllers (PLCs) are at the heart of these advancements, acting as powerful industrial computers that manage and control automated systems seamlessly. At Automated Solutions Australia (ASA), we specialise in delivering world-class PLC automation systems, setting new standards in manufacturing for industries such as automotive, aerospace, medical, and beyond. So with over two decades of expertise, ASA ensures that each PLC industrial automation system is designed to optimise operations, transforming complex workflows into streamlined processes.

What is a PLC and Why is it Essential in Automation?

A Programmable Logic Controller, or PLC, is an industrial-grade computer that manages, monitors, and controls automated processes. PLC industrial automation creates real-time operations, executing commands in milliseconds, which is essential for maintaining continuous production flow. Therefore, these controllers are critical for ensuring that complex machinery and robotic devices function harmoniously on production lines. So by automating repetitive tasks and enabling precise control, PLCs allow industries to operate at unprecedented levels of productivity and consistency.

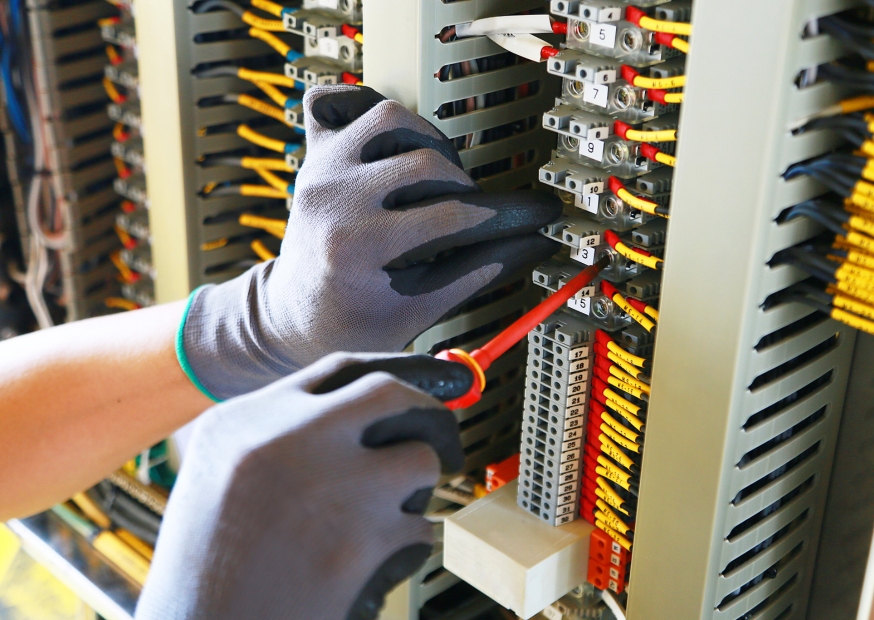

Key Components of PLC Industrial Automation

In any PLC industrial automation setup, several components work together to ensure smooth and efficient operation:

- Central Processing Unit (CPU): As the brain of the PLC system, the CPU executes commands, processes data, and stores essential information to keep operations running smoothly.

- Input/Output Modules: These modules serve as a bridge between the CPU and the machinery, allowing data and commands to flow seamlessly, ensuring the entire system responds accurately to real-time conditions.

- Human-Machine Interface (HMI): The HMI is a user-friendly interface where operators can monitor and adjust automation processes, offering full control and oversight of the automated system.

Each of these elements contributes to the robustness of PLC systems. Thus allowing for flexibility and adaptability across various industrial applications.

The ASA Advantage in PLC Industrial Automation

At Automated Solutions Australia, our engineering team is adept at designing and implementing PLC industrial automation solutions that are not only reliable but also customised to meet each client’s specific needs. We understand that no two industries are alike. Therefore we take pride in offering bespoke systems that integrate seamlessly with your existing setup. Our expertise with PLC automation solutions, enables unparalleled precision and efficiency. So from installation to ongoing support and training, ASA is dedicated to building lasting partnerships and ensuring our clients achieve optimal performance from their systems.

The ASA Difference

With PLC automation, Automated Solutions Australia doesn’t just install systems; we integrate solutions that transform your operational capabilities. Whether your industry is automotive, aerospace, medical, or any other, ASA’s PLC programming expertise coupled with the FANUC robots we integrate, is your gateway to optimised manufacturing and logistics performance.

Unmatched Support and Training with ASA

ASA’s commitment to our clients goes beyond installation. We provide comprehensive support and training to ensure your team is well-equipped to manage and maintain the PLC systems. Our goal is to foster confidence in every aspect of your automation solution, from the initial setup to daily operations. So with our ongoing support, your team can adapt to evolving production demands, ensuring that your automation system remains efficient and effective.

For businesses ready to elevate their productivity, ASA’s PLC industrial automation solutions offer a pathway to advanced, reliable automation. ASA is the ideal partner to transform your operational capabilities. Reach out to Automated Solutions Australia today, and let’s discuss how PLC industrial automation can drive innovation and efficiency within your operations.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Materials Handling Robots |

More (Recent) News Stories from Automation Solutions Australia:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia |Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Types of Welding Robots | Paint Mate | Australian Robotics | SCARA Robots | Robot Suppliers |Automation Robotics | Fibreglass Coating | Industrial Automation Industry | Manufacturing Automation | Welding Robot | Industrial Robotics Industry | Automatic Systems | Automated Manufacturing System | Auto Robots | Automatic Material Handling | Picking Robots | CNC Machinery Solutions | Australia Wide Automation | Automatic Coating | Collaborative Robots in Manufacturing | Automatic Solutions | Automated Robot | Robotics Integrators | Robotic Solutions |