In today’s competitive manufacturing landscape, integrating advanced technologies such as robotic lathe and robotic milling systems to keep your lathe and milling CNC machines running around the clock, can significantly enhance productivity, precision, and efficiency. Understanding the capabilities and applications of these robotic solutions can help businesses streamline operations and achieve superior results.

Robotic Lathe System in Machining Processes

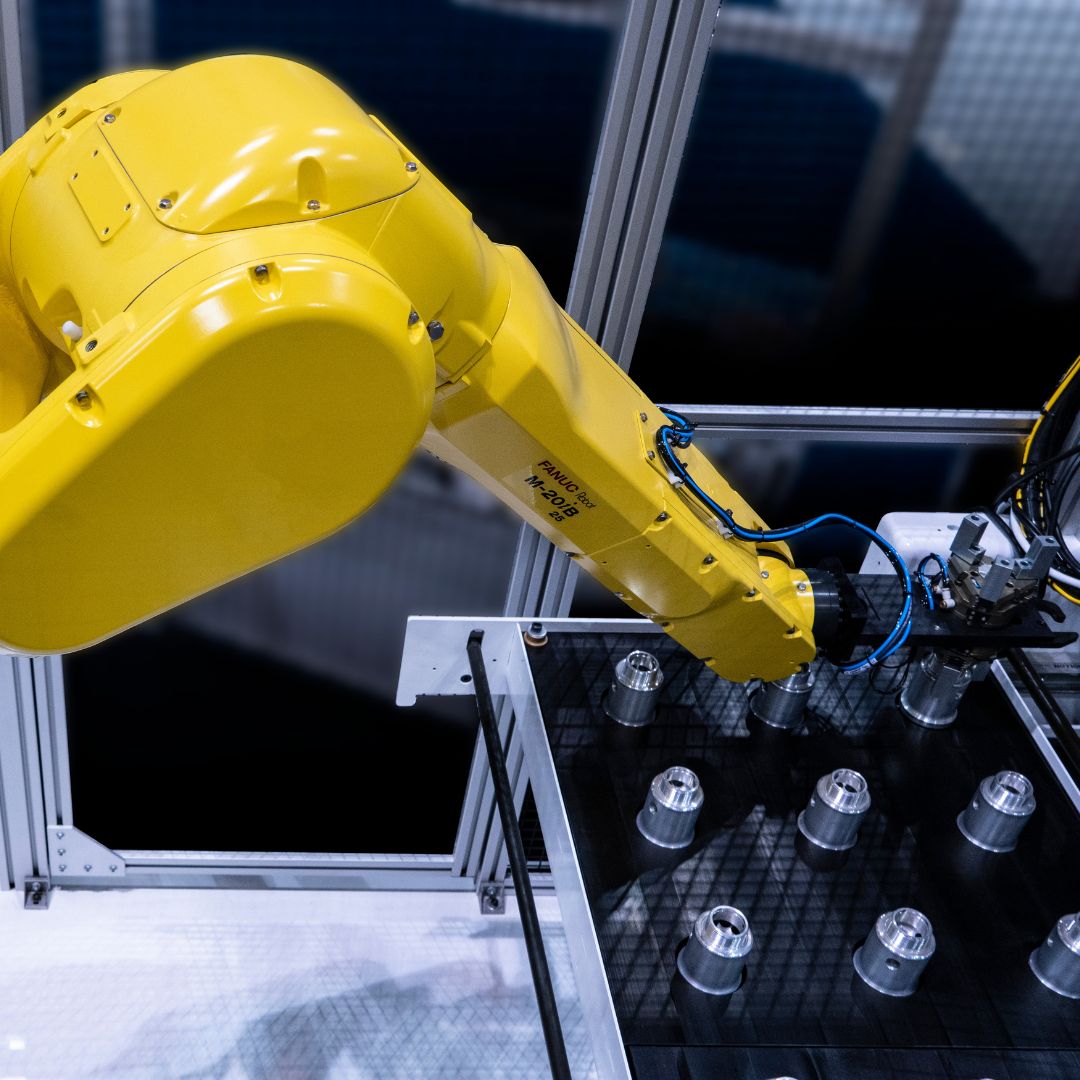

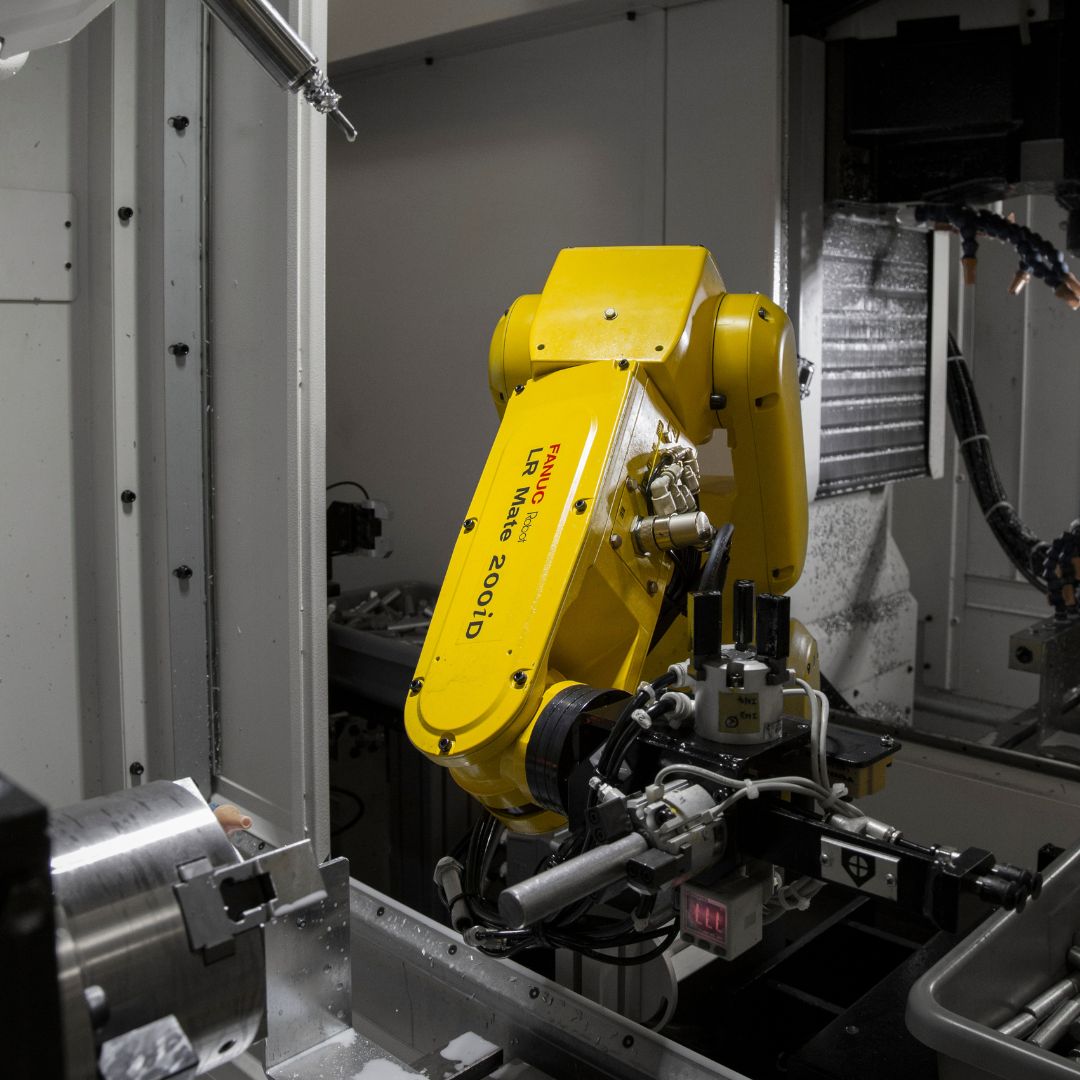

The use of a robotic lathe system in machining involves the use of automated robotic systems to manage the loading and unloading of workpieces into lathe machines. In addition, this process includes transferring machining pallets or directly manipulating the workpieces. Also, robotic lathe systems can handle the physical movement of cutting tools and integrate supportive processes such as deburring, washing, measuring, and marking. The automation provided by robotic lathe systems reduces human error. Thus it increases production speed, and ensures uniformity across large batches of parts. This makes the concept of a robotic lathe system indispensable in industries such as automotive, aerospace, metalworking and more.

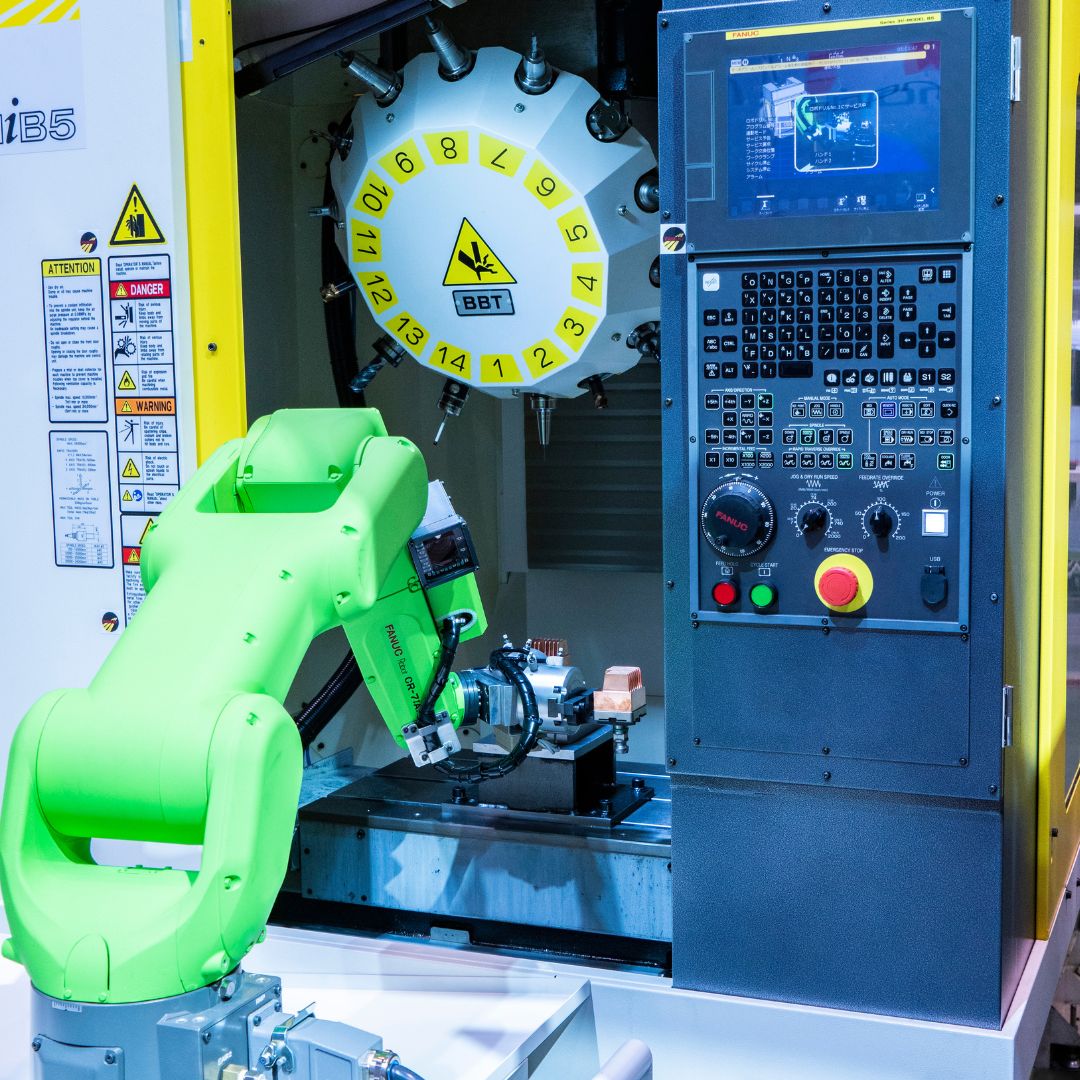

What is Robotic Milling?

Robotic milling utilises robots to manage the loading and unloading of materials into milling machines. Therefore a robotic milling system supplies raw material to the CNC machine, ensuring a continuous production flow. Whether it’s metal bars, plastic sheets, or wood panels, robotic milling keeps your CNC machine fed without pause. Therefore significantly enhancing throughput. The use of robotic milling allows for seamless integration of processes. These include cutting, shaping, and finishing, providing high precision and efficiency. So this makes robotic milling an essential component in modern manufacturing setups.

Automated Solutions Australia (ASA) | Experts in Robotic Milling and Robotic Lathe Tending

At Automated Solutions Australia (ASA), we integrate advanced robotic systems utilising FANUC robots, for both robotic milling and robotic lathe machining. Our expertise ensures that your production processes are optimised for maximum efficiency and precision. With our solutions, you can expect increased productivity, improved quality, and enhanced safety in your manufacturing operations. Contact us today to learn more about how our robotic milling and robotic lathe systems can transform your business.

Benefits of Robotic Lathe Systems and Robotic Milling Machine Tending

Increased Precision and Accuracy: Robots can perform tasks with a high level of precision, ensuring consistent quality in every part produced.

Enhanced Efficiency: Automation reduces the time required for setup and changeovers, leading to faster production cycles and increased throughput.

Cost Savings: By minimising human error and reducing labor costs, robotic systems can significantly lower production expenses.

Improved Safety: Robots can handle hazardous tasks, reducing the risk of injury to human workers and creating a safer work environment.

Flexibility: Robotic systems can be easily reprogrammed to handle different tasks, providing manufacturers with the ability to quickly adapt to changing market demands.

Automated Solutions Australia (ASA): Your Partner in Robotic Lathe and Robotic Milling Integration

At Automated Solutions Australia (ASA), we have over 20+ years of experience in robotic lathe systems an robotic milling machine tending, utilising the FANUC range for both robotic lathe systems and robotic milling tending processes. We have worked on a number of projects, with outstanding customer satisfication. Our team of experts works closely with clients. So as to design and implement customised automation solutions that meet their specific production requirements.

ASA is committed to helping Australian businesses enhance their manufacturing capabilities through the use of cutting-edge robotic technologies. By partnering with ASA, you can expect tailored solutions that boost productivity, improve product quality, and drive overall operational efficiency.

Ready to revolutionise your manufacturing process with automated robotic lathe systems and robotic milling solutions? Contact Automated Solutions Australia today to learn more about our FANUC robotic integration services and discover how we can help you achieve your automation goals. Visit our website or call us at 1800-ROBOTS (1800-762-687) to get started.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging Robots| Material Removal Robots | Shot Blasting and Peening |

More Recent News Stories from ASA:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Automation and Robotics | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Robotics in Business | Laser Welding | Picking and Packaging | Grit Blasting Explained |