MIG Robot Welding | Robotic MIG Welding | MIG Robotic Welding

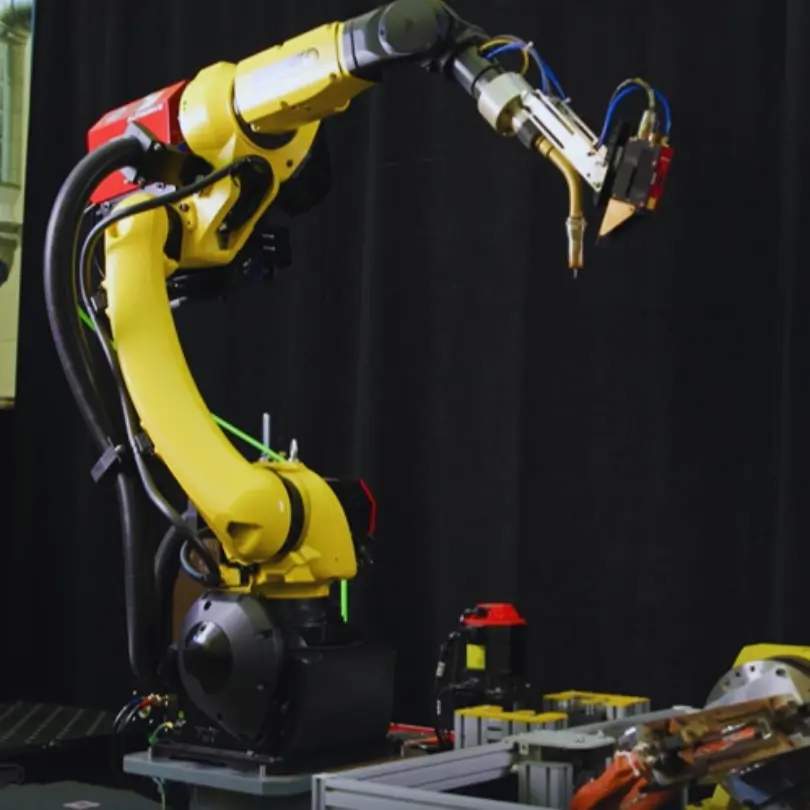

In today’s rapidly advancing industrial landscape, robotic systems integration has transformed traditional manufacturing processes. At Automated Solutions Australia, we offer the full range of FANUC welding robots. Specifically, in this article, we will focus on MIG robot welding, which offers unparalleled precision and efficiency. When it comes to robotic MIG welding or MIG robotic welding, the benefits are undeniable.

MIG Robotic Welding

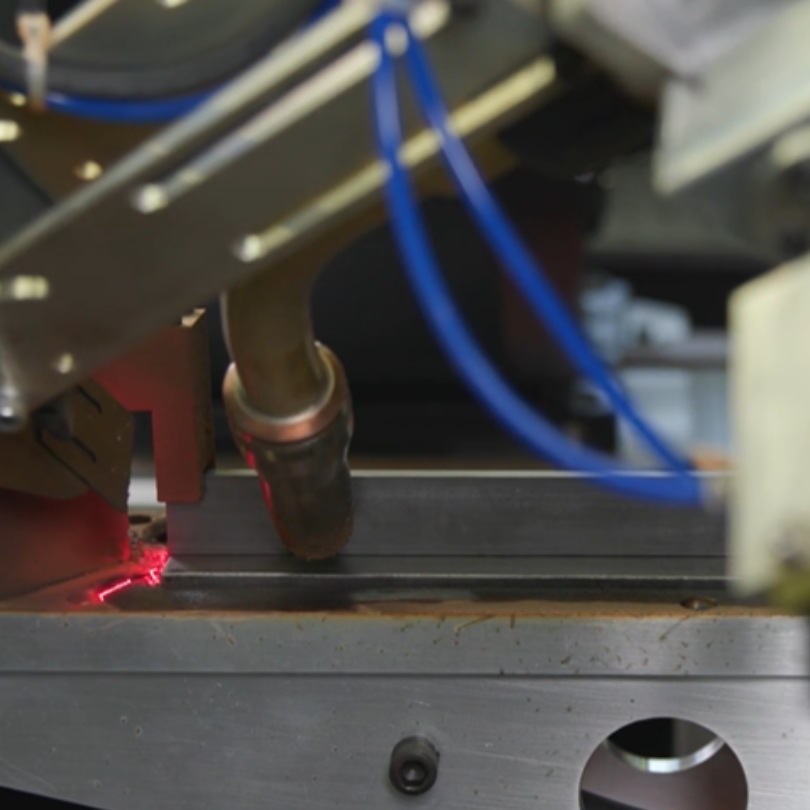

MIG robot welding involves using robotic arms equipped with MIG (Metal Inert Gas) welding tools to perform welding tasks. This process is highly efficient, providing consistent weld quality and reducing the potential for human error. So by automating the welding process, industries can achieve higher productivity levels and maintain superior quality standards.

The Many Advantages of Robotic MIG Welding

Increased Precision and Consistency: Robotic MIG welding ensures uniform welds every time, eliminating variations caused by manual welding.

Enhanced Productivity: Robots can work continuously without breaks, significantly boosting production rates.

Improved Safety: Handling hazardous tasks reduces the risk of injuries to human workers.

Cost-Effective: Over time, the efficiency and reduced error rates lead to substantial cost savings.

Applications of MIG Robotic Welding

MIG robotic welding is versatile and widely used across various industries, including automotive, aerospace, and heavy machinery. It is particularly beneficial in applications requiring high precision and repeatability, such as the assembly of vehicle bodies, construction of aircraft components, and fabrication of large structural elements.

Automated Solutions Australia | Your Partner in MIG Robot Welding

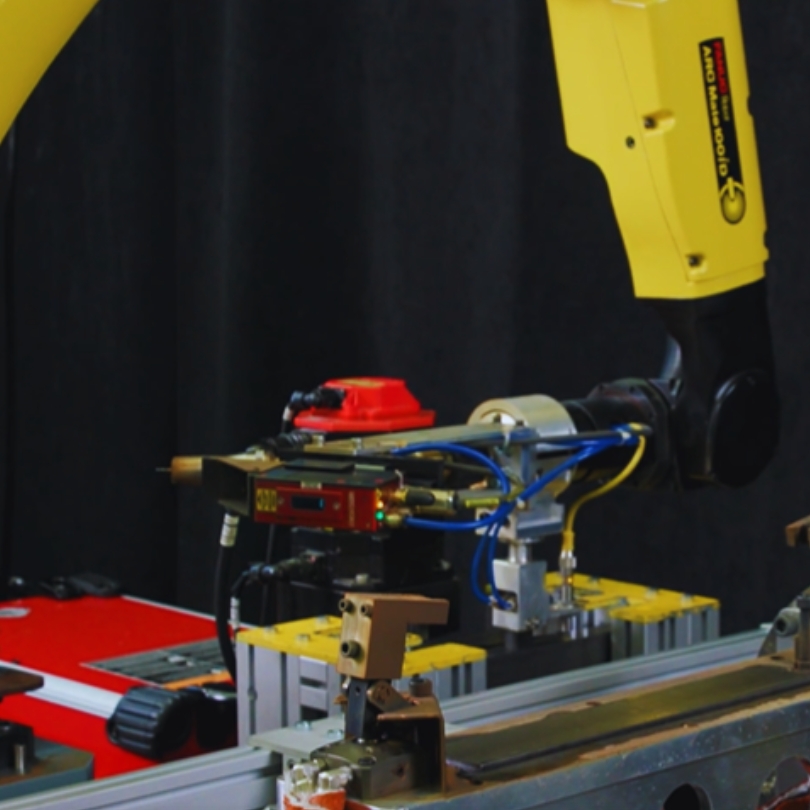

At Automated Solutions Australia (ASA), we specialise in integrating FANUC robots for our customers, Australia wide. When it comes to mig robot welding, we integrate the ARC series range for MIG welding applications. In addition, our expertise ensures that your manufacturing processes are optimised for maximum efficiency and quality. By leveraging advanced robotic MIG welding technologies, we help businesses achieve their automation goals and stay competitive in a global market.

Why Choose ASA for Your MIG Robotic Welding Needs?

Expertise: With years of experience, our team is proficient in designing and implementing customised MIG welding solutions.

Advanced Technology: We utilise the latest FANUC robots, known as the gold standard, for their reliability and performance in industrial applications.

Comprehensive Support: From initial consultation to installation and ongoing maintenance, ASA provides end-to-end support for all your robotic welding needs.

Transform your welding processes with the precision and efficiency of MIG robot welding. Contact Automated Solutions Australia today to learn more about our robotic MIG welding solutions and how we can help you integrate FANUC robots into your manufacturing operations.

Unlock the future of welding with ASA and FANUC robots.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging Robots| Material Removal Robots | Shot Blasting and Peening |

More Recent News Stories from ASA:

| Robot Welding Cell | Automated Picking Robots | Advantages of Robotic Welding | 6 Axis Welding Robots | FANUC Robot Programming | Paint Finishing in Australia | Industrial Manufacturing | Robot Integrator in Australia | Automation and Robotics | Industrial Applications of Robots | Robot Welding | Automation Engineering | Benefits of Robots | Materials Handling in Australia | Robotic Assembly Guide | A Guide to the History of Robots | Robotic Laser Welding | Robotics in Business | Laser Welding | Picking and Packaging | Grit Blasting Explained | Robotic Lathe and Milling | Robotic Integration | Programmable Logic Controllers |