In recent decades, CNC machining has helped to revolutionise the field of engineering, emerging as a dominant method of manufacturing. Within this article, we explore CNC machining, and discover the diverse range of services available.

The Evolution of the CNC Machine

The evolution of the CNC Machine is often attributed to John Parsons. An esteemed computer pioneer, Parsons contributed his expertise to an Air Force Research Project focusing on the improvement of helicopter blades and aircraft skin.

Parsons harnessed the computational power of an IBM 602A multiplier to precisely calculate the coordinates of helicopter airfoils. These calculations were then meticulously recorded onto punched cards, which he subsequently employed with a Swiss jig borer. This groundbreaking approach ultimately facilitated the production of numerous helicopter blades and aircraft skins. Within the history of CNC machining, this pioneering effort is recognised as the birth of the very first CNC machine.

Understanding the CNC Machine

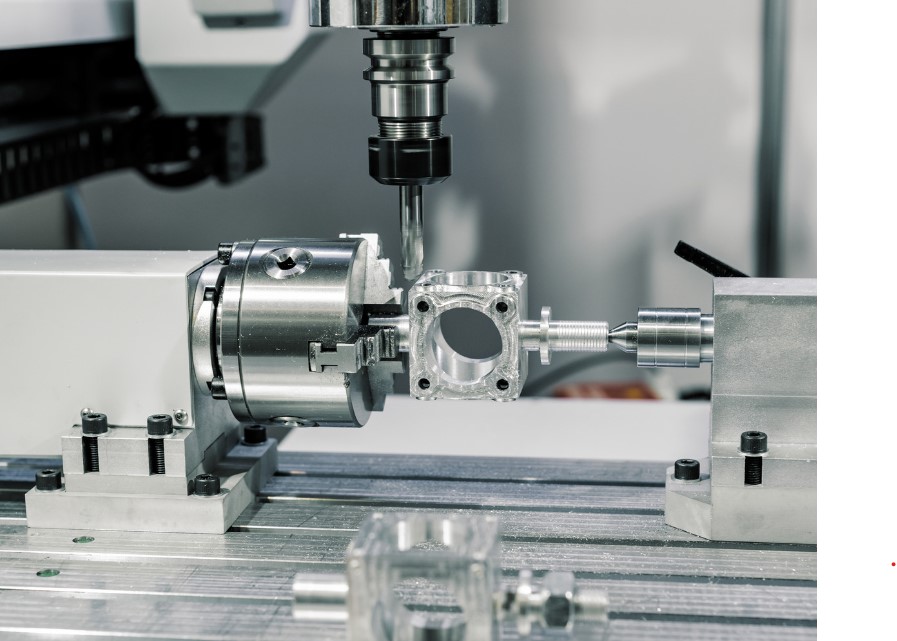

Delving deeper we shed light on the mechanics, advantages, and industries in which it shines.CNC machining removes material (rather than adding it) to create a finished part. Starting with a material block, they employ high-speed cutters to carve the material into the desired shape meticulously.

Operations of a CNC Machine | Applications of CNC Machining

CNC machines are directed by digitalised computers that automate, oversee, and control industrial machinery movements. Larger-scale industrial facilities typically integrate computers within the machines.The precise actions guided by this code vary depending on the type used.

Industries That are Utilising CNC Machines in Australia

CNC machining finds applications across numerous industries, such as aerospace, energy, electronics, automotive, manufacturing, and many more. It is particularly valuable in sectors where precision is paramount.CNC machining caters to a wide array of industries, offering versatility in creating accurate parts.

Types of CNC Machines Available Within Australia

Milling: Renowned for precision, CNC milling employs built-in tools for drilling and cutting. These machines use computer-guided drilling and cutting tools to shape materials.

Lathe: CNC turning involves rotating the material while cutting it, as opposed to moving cutting tools. CNC lathe machines manipulate and position materials as per computer instructions.

Plasma-cutting: Similar to milling machines, plasma-cutting CNC machines are used for cutting materials. They use a high-powered plasma torch capable of cutting through tough materials like metal.

Laser-cutting: In contrast to plasma cutting, laser-cutting CNC machines use lasers for precision cutting.

Benefits of Utilising CNC Machining | CNC Machines in Australia

Ideal for Large Quantities:It is cost-effective for producing moderate to large quantities of parts.

Compatibility with Various Materials: They can work with a wide range of materials, including metals like aluminum, stainless steel, magnesium alloy, and more.

Rapid Production: They are known for its quick turnaround times.

Exceptional Accuracy: They deliver precise results, with tolerances as tight as +/- 0.005mm achievable.

Versatile Finishing Options: They allows for a variety of post-processing and finishing options, including anodizing, polishing, plating, and heat treatment.

Ultimately it is reliable, precise, and diverse in terms of its applicability. Simply select the right supplier and digital manufacturing platform when ordering your parts, and success is within reach.

Automate Your CNC Machine with ASA’s Industrial Automation | Lights out 24/7 Production

At ASA we take automation to a whole other level by automating your CNC machine robotically utilsing Machine Tending Robots by FANUC. At ASA we work with all brands of machine tools, including Okuma, DMG Mori, Mazak, Doosan, Haas and many more. We have helped to automate a wide array of CNC machines across Australia and New Zealand. To read up on robotic automation and all it entails, click here.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

| Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |