What is a Pick and Place Robot?

A Pick and Place Robot is nothing short of a marvel in automation. Such robots have helped to revolutionise the manufacturing process by swiftly and efficiently picking up components or objects and precisely positioning them in designated locations. The introduction of Pick and Place Robots not only accelerates production rates but also liberates human workers, allowing them to channel their expertise towards more intricate tasks. Thus leaving the repetitive chores to the capable hands of these robotic assistants.

How Pick and Place Robots Work

A typical Pick and Place Robot, securely mounted on a stable platform, boasts the versatility to access various areas, making it an ideal choice for diverse applications. These robots rely on cutting-edge vision systems to identify, grasp, and transport objects from one point to another with absolute precision. They can be tailored to specific requirements, with a wide range of end-of-arm tooling options available for various tasks. Such tasks include; assembly, packaging, and bin picking. For example, a Pick and Place robot system may be tasked with swiftly gathering items for an order and depositing them into a packaging box or moving essential components to the next assembly station.

Applications of Industrial Pick and Place Robots

Pick and Place Robots extend their prowess to many applications beyond just the factory floor. These versatile robotic marvels find their roles in packaging, bin picking, and inspection, ensuring efficiency across the board. Here’s a glimpse of some of the most prevalent applications for Pick and Place Robots:

Assembly – In assembly scenarios, Pick and Place Robots gracefully handle incoming components from conveyors or designated sources, seamlessly integrating them into the product. The harmonious union of these components then proceeds to the next assembly phase, ensuring a streamlined workflow.

Packaging – Pick and Place Robots excel in packaging tasks, swiftly collecting items from designated areas, and orchestrating their meticulous placement within packaging containers.

Bin Picking – Pick and Place Robots handling bin picking are equipped with advanced vision systems that can discern colours, shapes, and sizes, even in bins containing a chaotic mix of items. They deftly select the right components, transferring them to their destined location for assembly or packaging.

Inspection – In inspection applications, Pick and Place Robots, equipped with advanced vision capabilities, expertly pick up objects, identify anomalies, and promptly remove defective parts or items, placing them in designated areas for further scrutiny.

Benefits of Pick and Place Robots

The benefits of a pick and place robot lies in its inherent swiftness and unwavering consistency. These adaptable robots can be customised to meet precise production requirements and are easily programmable for a multitude of applications. With compact designs and lightweight builds, Pick and Place Robots can thrive in space-constrained settings. In warehousing environments, they bolster output, especially in order picking and packaging operations, while offering an impressive return on investment for manufacturers. By taking on monotonous and repetitive tasks, these robots enhance productivity while alleviating the physical strain on human workers, ensuring a harmonious blend of efficiency and ergonomics.

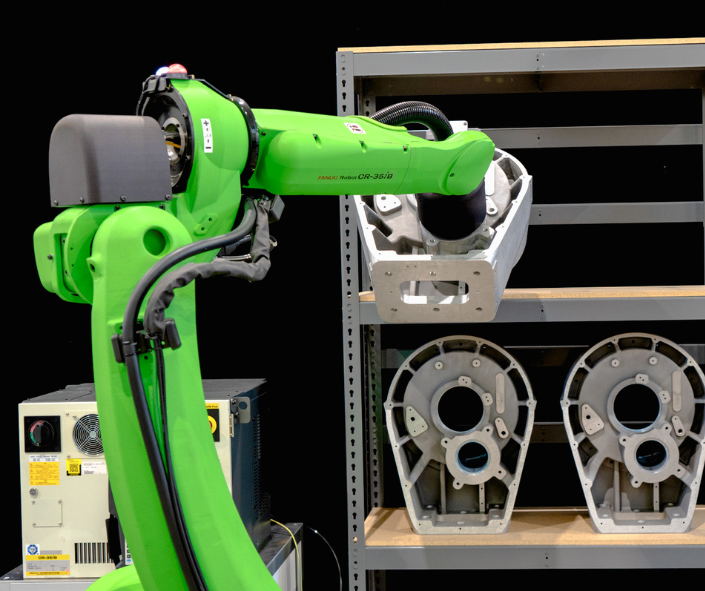

Why FANUC Pick and Place Robots Stand Out Above the Rest | FANUC – Gold Standard in Automation Worldwide

When it comes to industrial robots, FANUC stands as the undeniable champion in the field. Renowned for their unparalleled precision, reliability, and speed, FANUC Pick and Place Robots are the gold standard in the robotics industry. These robots seamlessly integrate into manufacturing environments, significantly enhancing production capabilities. With an array of models and configurations to choose from, FANUC offers tailored solutions that cater to a wide range of applications. When you choose FANUC Pick and Place Robots, you’re not just investing in automation; you’re investing in excellence.

Contact ASA, Today!

With over two decades of expertise in integrating FANUC robots, when you consider ASA you can expect excellence and reliability. Our long-standing experience not only showcases our proficiency but also reflects our deep understanding of robotic technology. As your ideal choice for a robotic integrator in Australia, we are dedicated to tailoring solutions that align perfectly with your operational needs. We invite you to reach out to us to discover how our expertise can drive efficiency, precision, and innovation in your processes. Partner with ASA, where our experience is your asset in navigating the dynamic landscape of automation.

Send Enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

| Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |