Highly efficient and precise machines have revolutionised automotive manufacturing processes, providing companies like ASA with a competitive edge. In this article, we will delve into the world of welding robots in the automotive industry, focusing on ASA’s expertise and our use of robots to perform various applications.

The Rise of Automotive Welding

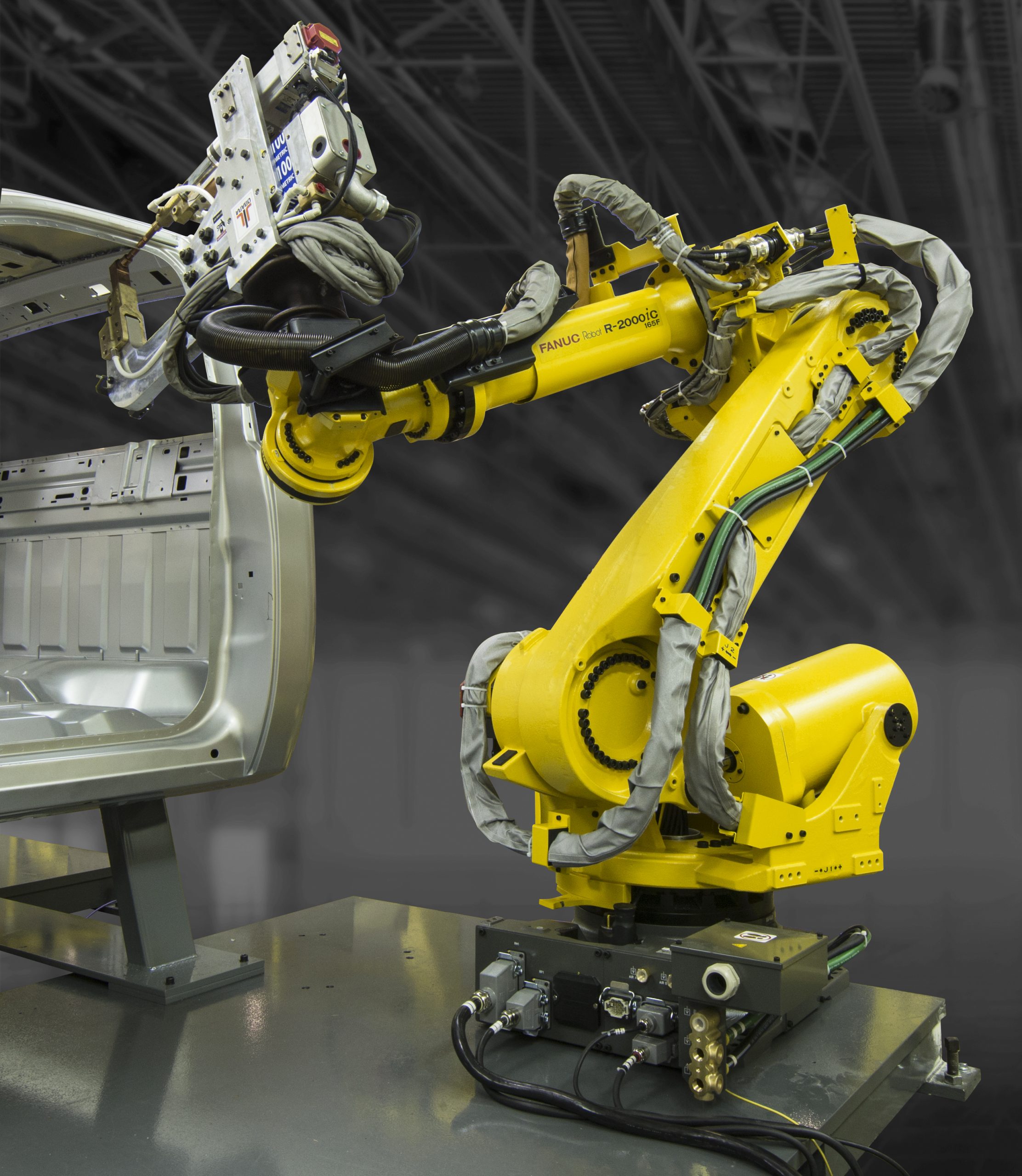

Welding robots have emerged as game-changers in the automotive manufacturing landscape. Traditional methods were labor-intensive and time-consuming. However, with ASA’s cutting-edge FANUC robots, the automotive industry can experience a significant shift towards automated and streamlined processes.

ASA | Your Trusted Partner in Automotive Welding Automation

We take pride in being a reliable partner for businesses seeking innovative automation solutions. With 20+ years of experience and a team of skilled engineers, ASA can deliver automation that elevates automotive manufacturing to new heights.

Unleashing the Power of FANUC Robots for Automotive Welding

At Automated Solutions, we choose FANUC robots for automotive welding due to their commitment to excellence. They are renowned robotics manufacturer, is known for its state-of-the-art technology, precision, and reliability. By harnessing the power of theserobots, we ensure that processes are executed flawlessly, adhering to the strictest quality standards.

Automotive Welding | Applications

Welding robots offer unparalleled versatility and flexibility, making them invaluable assets in various automotive applications such as:

Body-in-White (BIW) Welding: Effortlessly handle BIW welding tasks, joining various components of the vehicle body with utmost precision. This results in improved structural integrity and overall safety of the vehicle.

Chassis Welding: Robots are capable of welding chassis components, such as frames and subframes, ensuring optimal strength and durability, crucial for vehicle stability and performance.

Exhaust System Welding: Automation plays a vital role in assembling exhaust systems, maintaining tight tolerances for leak-free and efficient exhaust performance.

Spot Welding: Excel in spot welding applications, providing consistent and reliable welds on intricate automotive parts, increasing production efficiency.

Seam Sealing: Precise application of seam sealer is essential to protect vehicles from external elements.We ensure uniform and controlled sealing for optimal vehicle longevity.

Advantages of Automotive Welding

Enhanced Efficiency: Reduce cycle times, increase productivity, and minimise downtime, leading to a streamlined manufacturing process.

Improved Quality: The precision and repeatability guarantees consistent, high-quality welds, resulting in superior automotive products.

Safety and Ergonomics: By automating tasks, robots reduce the risk of workplace injuries and improve the overall ergonomic conditions for workers.

As the automotive sector continues to evolve, embracing the capabilities of automation becomes imperative for companies looking to stay ahead in the highly competitive market. With ASA’s innovative solutions, the future of automotive is brighter than ever before.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |