Robotic Arm | The Benefits of Robotic Arms

The primary reason driving the global robotics market is the growing need to lower operating costs in manufacturing facilities. To lower costs, you must lower production-process errors, wastage of raw materials, and accident rates in the workplace. Therefore the addition of robotic arms increases technological flexibility and productivity. Removing operators from potentially hazardous tasks by integrating a robot arm also increases the standard of safety in the workplace.

A robotic arm is usable in many industries, because it can carry out intricate, repetitive tasks with high accuracy even in dangerous situations.

What is a ‘Robotic Arm?’ | Robotic Arm Definition

A programmable robotic arm is essentially a kinematic chain of movable joints that rotate and/or have a linear displacement. Moreover, they function in a similar way to a human arm, without the same danger of harm. In addition, a robotic arm has an end effector, which is essentially to replace the human hand. Therefore connected components coupled with the programming determine what the end effector does. Robotic arms are flexible and useful in a variety of working settings. As a result, they are fast, reliable, and accurate and can be programmed to do a large number of tasks in a variety of environments. Robotic arms are truly revolutionsing a vast array of industries.

Industries Benefiting from Robotic Arms | Applications of a Robotic Arm

Today, every scale of manufacturing, including high-volume, heavy industries like the automotive production lines and a wide variety of pick and place applications, use robotic arms of various types. Thus automation of the process of loading items or products onto pallets, is possible with a robotic arm. Additionally, palletising becomes more precise, cost effective, and reliable when it is automated with robotic integration. Additional applications benefiting from a robotic arm include; machine tool tending, welding, paint, assembly, fibreglass and gelcoat, materials handling, and more.

Depending on the application, the end effector, or robotic hand, can be built to carry out any desired task, including welding, grasping, spinning, etc. For instance, in automotive assembly lines, a robotic arm can carry out a range of operations like welding and the rotation and placement of parts during assembly.

A robotic arm allows for the freedom of human workers from dangerous jobs that could result in physical harm. Additionally, when it comes to cobots, humans can also work safely alongside robotic arms, or in the case of cobots, can work in total collaboration with them.

Precision and Versatility

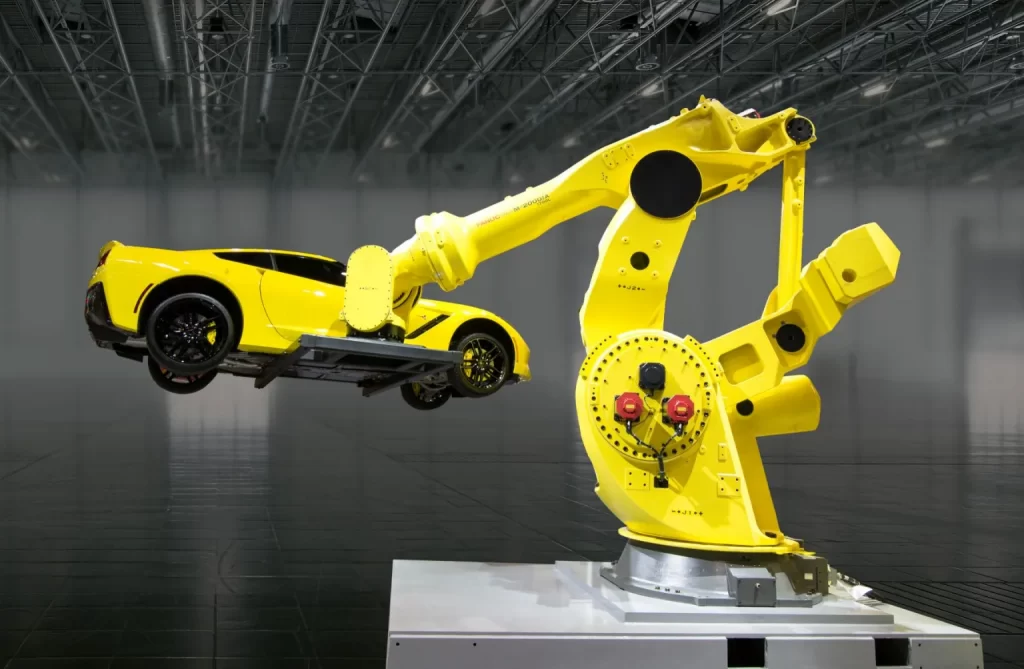

FANUC’s industrial robotic arms are renowned for their precision and versatility in automation. These articulated robots excel in various industries, equipped with advanced end effectors like grippers that enhance their functionality. These robotic arms play a pivotal role in manufacturing processes, handling tasks from assembly to welding with unparalleled efficiency. FANUC’s range of robotics products includes articulated robot types designed to integrate seamlessly into production lines, offering robust solutions for automation challenges. Whether gripping delicate components or performing heavy-duty tasks, FANUC robots exemplify innovation in industrial automation, driving productivity and quality across diverse sectors.

Automated Solutions Australia | Robotic Arm Integration in Australia

ASA is your go-to for FANUC industrial and collaborative robots. Indeed our team are experts in FANUC robots, and robot ar,ms, managing everything from ideas to designs, setup, and aftercare. Furthermore, we at Automated Solutions Australia love aiding Australian businesses in their automation journeys, thereby making our manufacturers globally competitive.

ASA is your go-to provider for FANUC industrial robots. Our expert team specialises in robotic arms, industrial robotic arms, and general robotic integration, managing everything from initial concepts and custom designs to system setup, programming, and ongoing aftercare. Whether you need robotic arms grippers, end effectors, or advanced manipulators, we deliver tailored solutions using cutting-edge robotic mechanisms and mechanical arms. We offer a wide range of industrial robots for sale across Australia. Furthermore, we at Automated Solutions Australia are passionate about helping Australian manufacturers embrace industrial automation, thereby making their businesses more efficient, productive, and globally competitive. With over 20 years of experience in robotic arm installation and automation technology, our top priority remains delivering outstanding customer success. So, for any FANUC robot, industrial robot, or robotic automation project, think of us as your trusted local experts.

Given our 20-year history, our top priority remains our customers’ success. So, for any FANUC robot needs, think of us as your Australian experts. Don’t delay! Call us today at 1800 ROBOTS.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot |