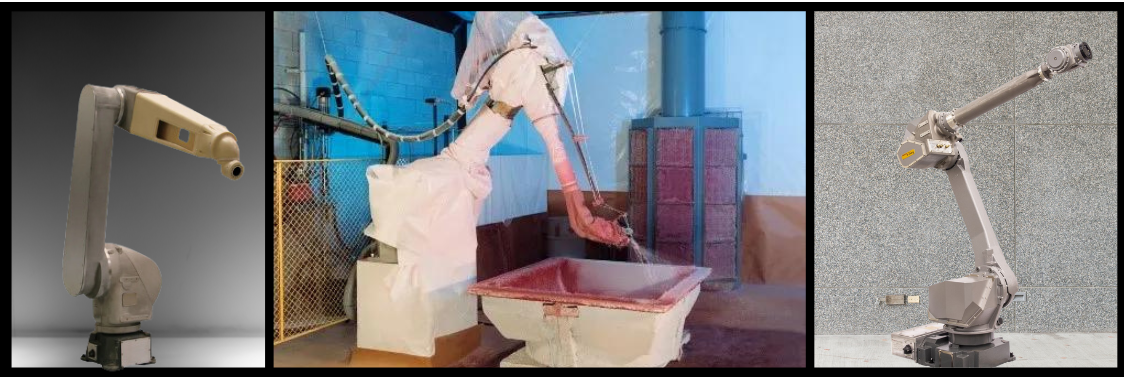

Automated Solutions Australia are able to offer a range of fibreglass and gelcoat robots from the FANUC range

Fibreglass and Gelcoat Robots | Overview

The compounding impact of increasing environmental regulations, rising material costs, and pressure to innovate are driving Boat, Swimming Pool and Caravan manufacturers to turn to robotic solutions for fibreglass and gel coat applications within the composite sector. The gains in product quality and reliability, material savings and wastage, labour savings, improved cycle times, increased employee safety and reduced emissions cannot be ignored. The FANUC range of paint robots are the perfect choice to automate your fibreglass and gelcoat manufacturing facility.

Benefits of Fibreglass Robots and Gelcoat Robots

Product quality and reliability

Gelcoat quality directly influences a product’s final appearance. If the application is applied too thick, the surface becomes susceptible to cracking. THus it becomes too thin and the gelcoat won’t cure correctly. Relying on a proven FANUC paint robot gives you a repeatable outcome that can eliminate these quality concerns.

Overspray wastage

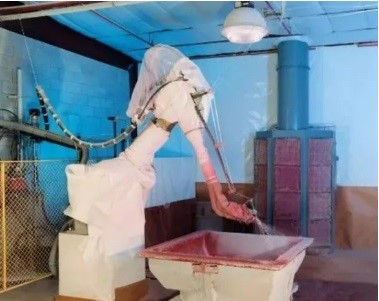

With precise trigger timing and constantly repeatable motion, a robotic application pattern dramatically reduces variance in the amount of resin or fibreglass used, reduces overspray and ensures uniform coating thickness.

Shorter cycle times

A fibreglass or gelcoat robot can repeat difficult ergonomic tasks with speed and accuracy. Fan patterns can be varied on the fly which enables improved coverage and higher deposition rates. With a Fanuc high speed painting robot, you can expect shorter cycle times and high equipment availability on every shift.

Even more reasons to automate with Fibreglass and Gelcoat Robots

Material Savings

Reducing waste at the point of origin is the key to material savings. Fibreglass and gelcoat robots and their dispensing systems are very accurate, with precise trigger timing and constantly repeatable motion dramatically reducing variance in the amount of resin or fibreglass used. Closed loop material delivery systems can be included in a robotic solution to monitor and provide consistent fibre chop application, adjusting the amount of fibre material delivered in line with minor changes in the manufacturing environment.

Increased employee safety and environment

Fibreglass and gelcoat robots are designed to operate in Zone 1 Class 1 environments, meaning potentially hazardous tasks can be completed in a far safer manner, reducing the exposure of employees in a manufacturing facility to potentially hazardous environments. Robots don’t need cumbersome PPE, breaks or suffer from repetitive strain injuries – all very real issues in a fibreglass manufacturing shop.

Automated Solutions Australia (ASA) can assist with identifying gains in product quality and reliability, material savings and wastage, labour savings, improved cycle times, increased employee safety and reduced emissions for your fiberglass and gelcoat processes.

How can Automated Solutions Australia Help?

Whether you are a large or small manufacturer, if you are looking at Fibreglass and gelcoat robots for your manufacturing process, we invite you to contact Automated Solutions Australia to explore the FANUC range today on 1800 ROBOTS. Our industrial engineering team at ASA are FANUC robot specialists, from concept to system designs, installations, programming and support. At Automated Solutions Australia (ASA) we thrive on helping Australian business of all sizes achieve their automation goals, enabling manufacturers to compete on the world stage while building sovereign capability. Call us today!

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation | Robotic Assembly | Materials Handling | Robotic Welding | History of Robots |