The Evolution and Impact of Robot Welding

Robot welding has revolutionised the welding process by automating both the welding action and the handling of parts. This innovation is particularly significant in high-production industries like automotive, where it enhances efficiency and safety. Therefore robot welding, distinct from manual operations, allows for consistent, high-speed welding, reducing errors and increasing productivity.

The Rise of Automated Robot Welding

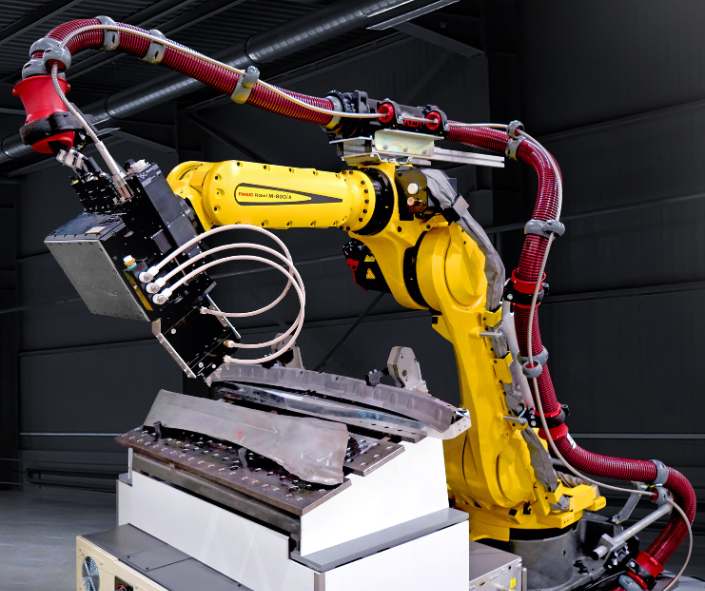

Since its significant uptake in the 1980s, robot welding has seen rapid growth, particularly in arc welding, now commanding a substantial portion of industrial robot applications. Therefore, the integration of robots in welding tasks has been a game-changer. Offering precision, repeatability, and a safer environment for workers. Robots like the FANUC M-710iC/20M, integrated by Automated Solutions Australia (ASA), form part of this evolution, providing adaptable and reliable solutions for various welding needs.

Advantages of Robot Welding

Robot welding offers numerous benefits, including increased productivity, decreased injury risks, and lower production costs. Consequently, such advantages result in a consistent quality of work, reduced labor costs, and minimised waste, making robot welding a valuable asset in modern manufacturing.

Expertise in Robot Welding Integration

At ASA, we specialise in integrating the FANUC range of robots for welding, offering tailored solutions that enhance the metal fabrication industry’s efficiency and safety. Therefore our approach includes detailed needs analysis, process enhancements, and the use of advanced 3D CAD programs for pre-production planning, ensuring optimal performance and cost-effectiveness.

Robotic Arc Welding Systems with FANUC Robots

FANUC’s arc welding robots, known for their extensive range and user-friendly programming, enable businesses to maximise productivity and quality while minimising costs. The FANUC ARC Mate series (click here to learn more), exemplifies how robotic technology can be leveraged to improve welding processes, offering precision, speed, and reliability.

Innovative ARC Welding Cobot Solutions by FANUC

FANUC’s collaborative robots, like the CR-15iA and CR-7iA, embody the fusion of advanced robotics and collaborative operation, enhancing flexibility and efficiency in welding tasks. Additionally, these cobots, equipped with ARC Tool Software, streamline programming and operation, making them ideal for a range of welding applications.

Spot Robot Welding

The Future of Manufacturing with Robot Welding

Robot welding represents a significant technological advancement in the manufacturing industry, offering a host of benefits that drive efficiency, quality, and safety. With ASA’s expertise in automation engineering and the advanced capabilities of FANUC robots, businesses can transform their welding processes to achieve unparalleled results.

To explore how robot welding can revolutionise your manufacturing operations, contact Automated Solutions Australia today and harness the full potential of automation engineering in your production processes.

To read more about our range, click here.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines| Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Unlock the Future with Automation Systems | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting |The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |