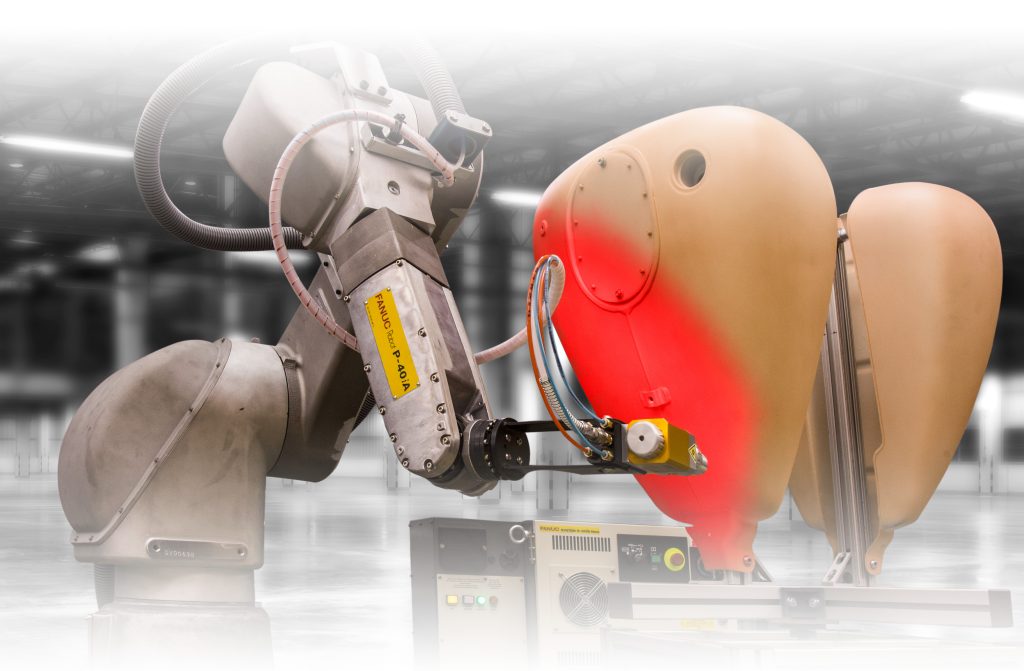

Paint booth robots, particularly FANUC robots, are revolutionising manufacturing automation worldwide. Global sales have continued to surge at an impressive year-over-year average growth rate of 15 percent.

The future of manufacturing undeniably belongs to automation, and it has never been more accessible or cost-effective. As technology advances, the advantages of integrating paint booth robots into your production processes become increasingly apparent.

Advantages of Painting Automation with FANUC Robots

Cost Efficiency: While the initial investment in automation and paint booth robots may appear substantial, the long-term benefits are undeniable. Automating the finishing process increases output, reduces costs, and ensures significant bottom-line savings over time.

Quality Assurance: Maintaining consistent product quality is paramount, especially in the context of painting. FANUC robots guarantee uniform spray gun parameters and motion. Enhanced consistency results in reduced material wastage and improved throughput.

Technological Precision: Precision engineering of equipment for mixing and spraying improves quality, reduces waste, minimises VOC emissions, and boosts overall productivity. Accurate mixing and ratio assurance for two-component materials optimise material performance.

Waste Reduction: Implementing paint automation can reduce material consumption by up to 30 percent, thanks to the precision and accuracy of robots. Additionally, incorporating plural component proportioners and electrostatic spray applicators further reduces waste.

Flexibility: FANUC robots are easily reprogrammable to adapt to new tasks, eliminating the need for creating new fixtures. This flexibility not only saves time during changeovers but also cuts costs. Automation facilitates more frequent material and colour changes, simplifying production planning.

Workforce Benefits: Robots operate tirelessly, 24/7, reducing labor and overhead costs. They excel at repetitive tasks, reducing on-the-job injuries and job dissatisfaction. Moreover, robots can handle hazardous jobs, allowing human workers to focus on tasks requiring decision-making and judgment.

Automated Paint Booth Considerations

Before investing in automation, consider factors such as production scale, labor intensity, and initial investment. High-volume parts and labor-intensive operations are ideal candidates for paint automation, as they reduce fixture and programming costs.

Keys to Successful Implementation

Successful implementation of an automation system requires thorough groundwork. This involves a needs analysis, accurately mapping the process, and making cost comparisons to current production. Benefits and risks should be carefully assessed, and the right solution selected.

Automation should be viewed as a long-term strategic decision, providing opportunities to redesign processes and enhance overall value streams.

Why Automated Solutions Australia (ASA)?

When it comes to servicing your FANUC paint finishing robot, ASA is a wealth of knowledge. Therefore, we provide servicing and support as part of our process.

For medium and larger customers, we offer a specialised service known as Automated Facilities Support (AFS), where our team focuses on supporting your facility to ensure optimal running, process engineering, and continuous monitoring of your Paint Booth robots and equipment. This comprehensive approach represents our gold standard of customer support, providing you with peace of mind that you will always have dedicated support in the future. We seamlessly integrate ourselves into your customer solution, assigning dedicated experts for paint finishing advice and production support, exclusively for your Paint Booth robots. Clients who utilise our AFS often experience industry-leading mean time to repair (MTTR) and mean time between failures (MTBF), ultimately optimizing their manufacturing processes.

Contact us today for all your paint finishing needs, including breakdown support, servicing, repair, and maintenance, specifically tailored to your Paint Booth robots.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |