Automated Solutions Australia (ASA) Choose FANUC for our Robotic Vision Inspection System

Robotic Vision Inspection System Overview

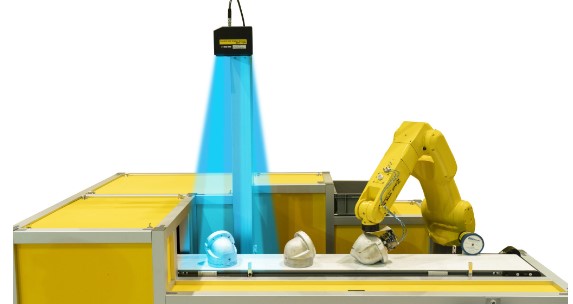

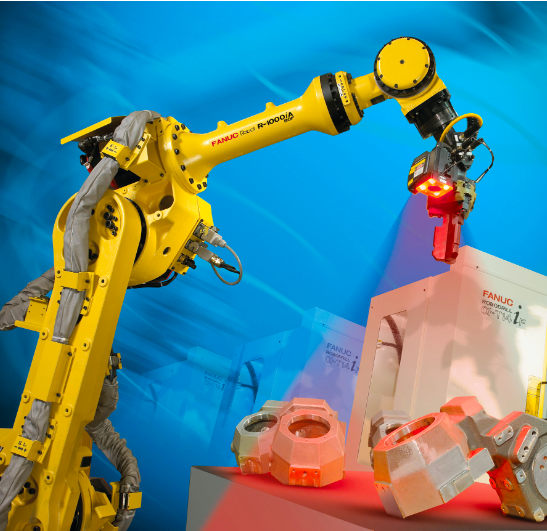

Automated Solutions Australia (ASA) utilises FANUC robots for robotic vision inspection systems. FANUC is the only creator of industrial robots and cobots that combine vision technology with its inspection robots. In fact, every new FANUC robot is “iRVision Ready.” iRVision is a unique, integrated visual detection technology. It allows FANUC robots to see, hence making quality inspection quicker and more intelligent.

ASA’s experts are committed to supplying integrated robotic vision inspection systems for companies who want to conduct product quality inspections. These solutions are easy to use. Moreover, they may be applied without the need for complex programming or skills.

Robotic Vision Inspection System – iRVision

As new sectors develop and companies modify their procedures to remain up to date with the most recent market trends, chances to boost output and overall profit arise. These systems may enhance production in areas such as e-commerce and pharmaceutical manufacturing. They are also widely used in robotic sorting of recycling.

Setting up iRVision for a visual exam is simple since the software leads you through each step. The basic iRVision package includes a robust vision toolkit to enable any bespoke vision system, making robotic vision inspection systems very user friendly.

Moreover, iRVision does not need an interface to external devices or extra gear (such as PCs, monitors, or side cabinets) for installing or operation. The setting of the robotic visual inspection process may be directly on the robot controller, on the Teach Pendant, or on any IE-capable device. All FANUC inspection robots and controllers are used with the iRVision solution due to the fact that the controller hardware is prepared for vision.

Robotic Vision Inspection System Applications

Presence/Absence detection

Part authentication

Detection of defects

Automatic eyesight evaluation

OCR/OCV refers to optical character recognition.

Similarity matching

Colour verifying

Robot led by vision Sorting

Barcode scan and tracking

And more…

Whether you are a large or small business if you looking at robotic vision inspection systems for your manufacturing process, we invite you to contact Automated Solutions Australia to explore the FANUC range today on 1800 ROBOTS. Our team at ASA are FANUC robot experts. From concept to system designs, installations, programming and support. At Automated Solutions Australia (ASA) we thrive on helping Australian business of all sizes achieve their goals, allowing you to compete on the world stage. Automated Solutions Australia are your industry leading experts.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation | Robotic Assembly | Materials Handling | Robotic Welding | History of Robots |