Automated Solutions Australia (ASA) is a full-service automation company dedicated to helping out customers achieve their full potential through automation

What is CNC Machine Automation?

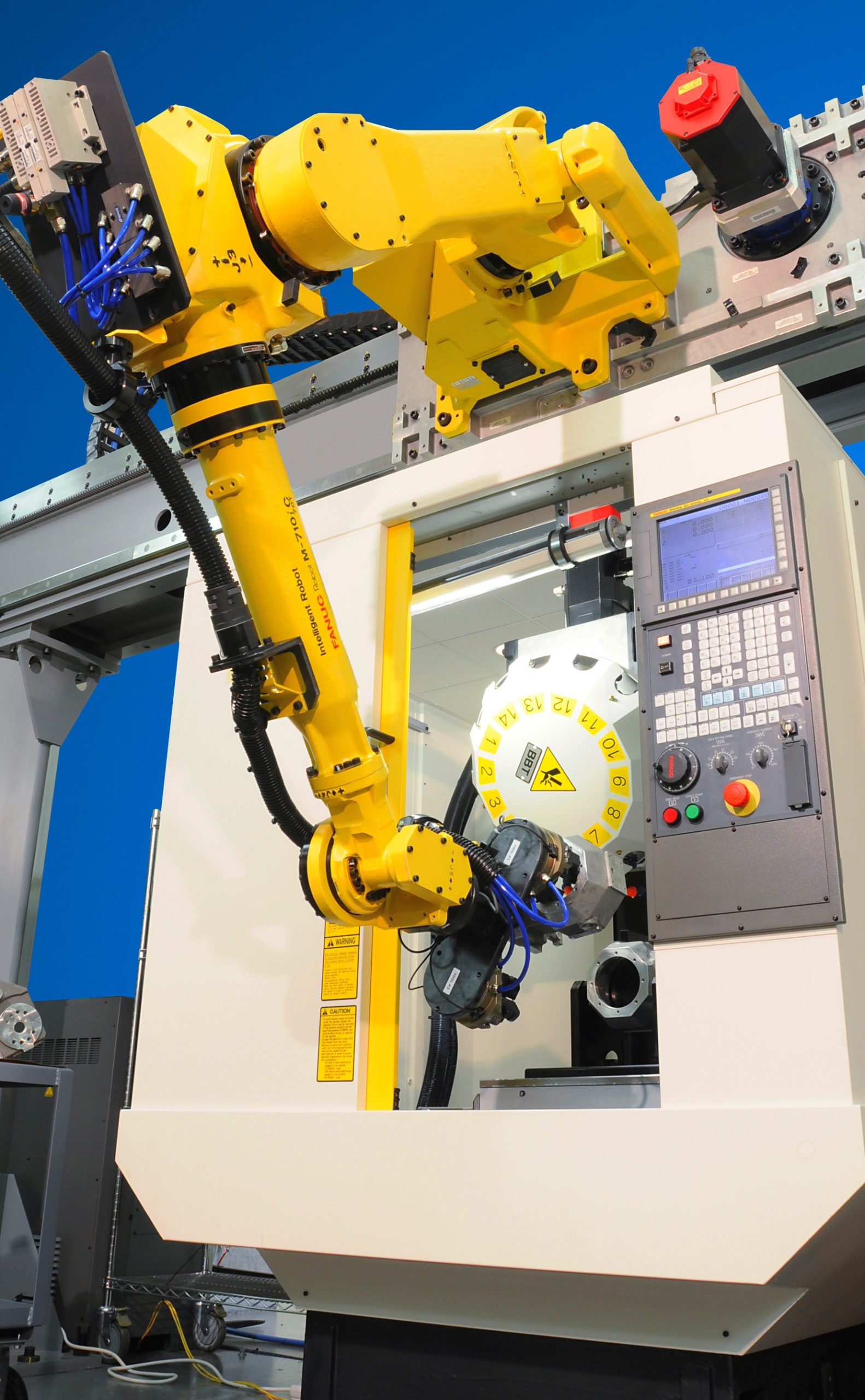

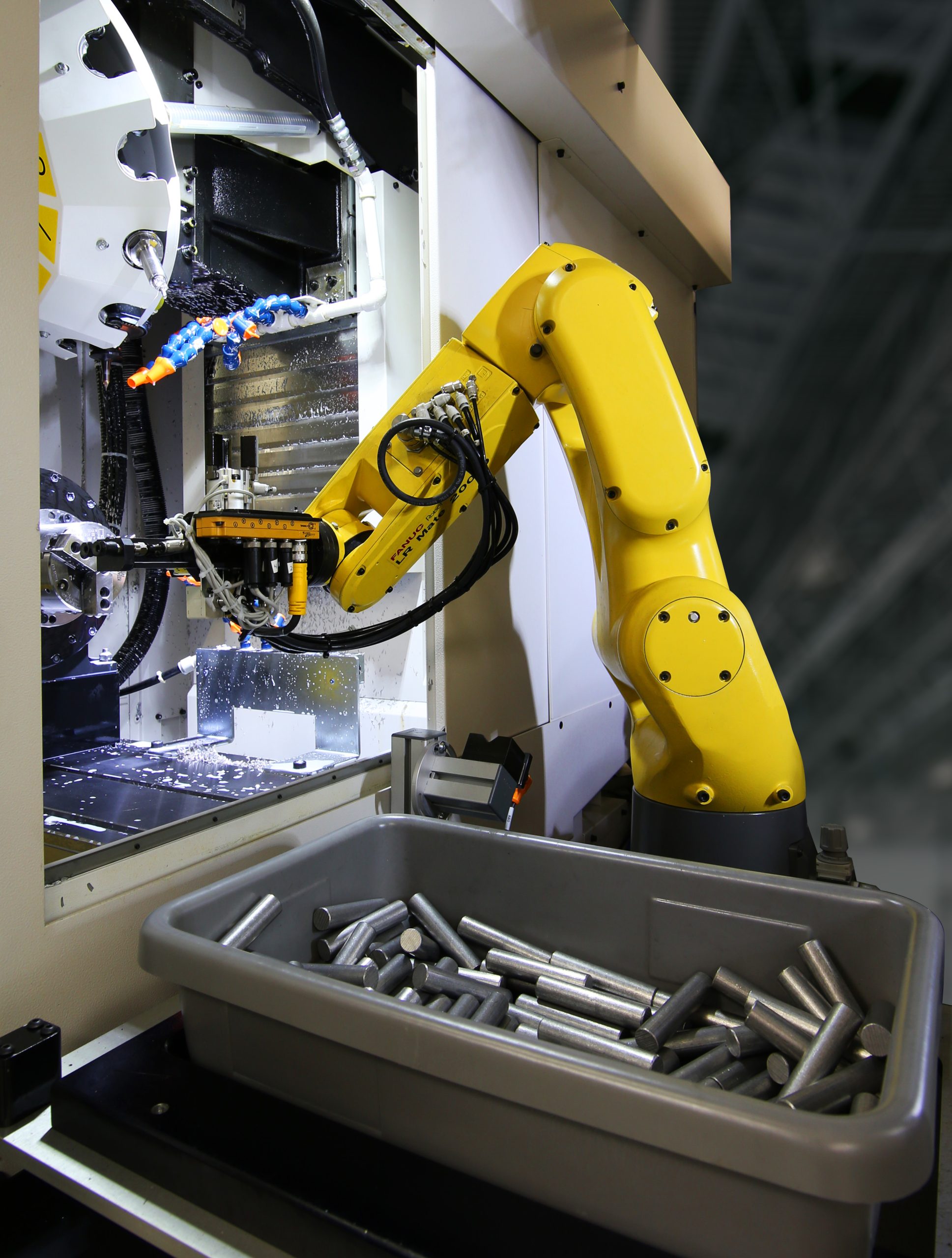

The method of using a robot system to autonomously load and unload a production machine is CNC Machine Automation. Ultimately, the layouts, workflows, workpieces, and needs vary so much from application to application, that at ASA, we offer a broad range of custom and standard robotic automation. Above all, lathe and milling machine load and unload, top loading of moulding machines, and press tending are key examples of common machine tool tending uses. Furthermore, maximizing the uptime of the main machine tool is the design goal in these applications.

Lights Out Production | 24/7 Productivity with CNC Machine Automation

CNC Machine automation allows machines to run continuously. Accordingly, this is without interruption for the length of a shift or overnight for “lights out” production. Additional advantages include an increase in machine utilisation. Ultimately, this frees up the worker to operate multiple machines, program, or carry out downstream processes, leading to higher and more consistent overall output rates. Additionally, robot rails can be added to allow robots to operate numerous machine tools when necessary, this increases their flexibility. Ultimately, the design of the robot’s changeover grippers also enables the robot to handle a variety of parts and/or a substantial switch between pre-machined and machined parts without the assistance of an operator.

Benefits of CNC Machine Automation:

- Greater flexibility as opposed to set automation

- Maximise productivity with faster and more efficient operations

- An increase in system uptime

- Being able to manage multiple machines

- Decreased running costs

- Increased calibre

- Capacity to perform additional procedures

Whether you are a large or small manufacturer, if you looking at CNC Machine Automation for your manufacturing process, we invite you to contact Automated Solutions Australia to explore the FANUC range today on 1800 ROBOTS. Our engineering team at ASA are FANUC robot specialists, from concept to system designs, installations, programming and support. At Automated Solutions Australia (ASA) we thrive on helping Australian business of all sizes achieve their automation goals, enabling Australian manufacturers to compete on the world stage. For all your industrial machine tool tending needs, Automated Solutions Australia are your industry leading experts.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |