Robotised surface preparation is synonymous with improved productivity and efficiency, but what does that really mean if you are a manufacturer in the Aerospace & Defence sector supply chain?

Surface preparation, specifically shot peening, assists in the correct preparation of a surface to avoid premature fatigue, corrosion, wear, galling and fretting which is vital for Aerospace and Defence suppliers.

It’s not unusual to hear reports of higher levels of output, product quality and flexibility amongst the benefits of automation. This article looks at where those real savings can be achieved, at what cost, and how the benefits can be quantified.

Cost Benefits

The first and most obvious benefit in moving to a robotic surface preparation solution is a reduction in capital and operating costs, the latter being in the form of direct or overhead costs. Compressed air consumption is a case in point. Studies suggest that between 10 to 30% of industrial energy consumption costs go toward compressed air.

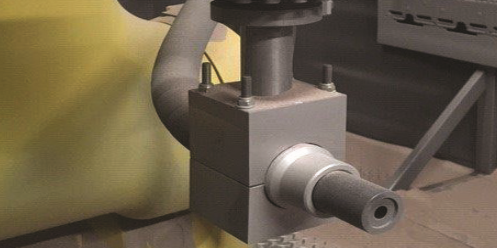

A robot fitted with a single blast nozzle can achieve an equivalent or superior finish for a fraction of the compressed air consumption compared to an automatic machine requiring six to eight nozzles.

Let’s put that into real numbers. At our warehouse in Adelaide, we pay 36.46 cents per KWH for our electricity – some of the most expensive in the world!

For arguments sake, consider an air compressor which uses 7 KWH to generate 1 cubic metre of air per minute, or 0.198 KWH per cubic feet per minute (CFM). If for instance, the complex automatic machine uses 8 x 45 CFM nozzles to prepare the part, or 360 CFM, at the price we currently pay for electricity, this equates to $26.02 per hour of operation. Alternatively, a robot fitted with 1 x 75 CFM nozzle would cost just $5.42 per hour to run.

The electricity costs for this one application in a facility running two, eight-hour shifts, five days per week, for 52 weeks a year, would reduce from $108,232 to $22,548, close to an $86,000 saving per annum.

But, that’s not the only direct cost saving – the media consumption used for the blasting is also dramatically reduced because of there is no cross firing of guns. The media used in shot peening varies from application to application, but is generally cast steel, cut-wire, stainless, glass, ceramic or other materials. For this reason, the cost saving on the usage of the shot is very application specific, but what isn’t is the reduction in waste, which can be as much as 30% based on previous applications.

In addition to compressed air and material savings, the ancillary media reclamation system required for one nozzle versus six or eight is much smaller in scale, which has a flow on effect to other smaller screen classifiers, smaller shape classifiers, and smaller cyclone and dust collectors. The reduction in size and scale of this equipment results in a lower capital investment and a reduction in the required footprint for the application. Further to this is the obvious labour savings associated with robotising the application.

Improvements in quality and consistency

Another benefit of robotising a shot peening application is the improvement seen in the product quality and consistency.

Blasting steel serves to clean the substrate and produce an etched surface profile (anchor pattern) when the abrasive strikes the metal. The surface profile improves the ability of a corrosion prevention coating to adhere to the surface, and at the same time, it is designed to generate an even compressive stress pattern, eliminating microscopic defects in the surface of the parts – critical to aerospace applications.

Permissible stress levels for various materials are improved through the adoption of this process, increasing the overall life cycle of a product. Because of the nature of a repeatable robotic program, where target distances are maintained, and speed is used to minimise crossfire, a robot has the ability to generate a surface profile that is far more consistent in application measures such as Ra and Rz.

Furthermore, the optimal shot impact angle can be maintained and repeated, providing an even residual stress profile across the part that may otherwise have not been achievable with a manual application.

Reduction in downtime

Increased manufacturing uptime is another tangible benefit from robotic shot blasting.

Operators in a manual application are required to wear heavy personal protective equipment that can be stifling, and as a result, operators require significant rest allowances to meet occupational health and safety requirements . In comparison, robots can operate around the clock, and reduce the requirement for constant visual inspection of the part due to their inherent repeatability.This greatly increases the uptime of the cell.

Advances in offline programming capabilities for robot systems mitigates the need for excessive downtime between production runs as parts can be simulated offline, and new parts can be brought online without significantly impacting production schedules.

The manufacturing uptime is also higher when compared to fixed peening machines, which may need significant downtime between different types of parts for nozzle adjustments. The flexibility of running a robotic application means that there is a minimal amount of downtime between product changes, as the industry drives towards smaller batch sizes.

In conclusion, robotising blasting applications in the Aerospace and Defense supply chain provides a unique opportunity for manufacturers to reduce their operating expenditure, while improving their product quality and consistency.

Manufacturers can look forward to a high cell uptime because of the reduced need for inspection and the ability to program new parts using offline programming tools. Cells can operate night and day, providing the greatest return on investment, whilst reducing the footprint of the blasting area.

In the competitive world of surface preparation, robotic solutions are enabling manufacturing efficiencies that are once again allowing companies to compete with low cost overseas markets. The question is, what will you do – innovate, or evaporate?

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |