In today’s fast-paced automotive industry, innovation and technology play pivotal roles in boosting productivity and maintaining competitive advantages

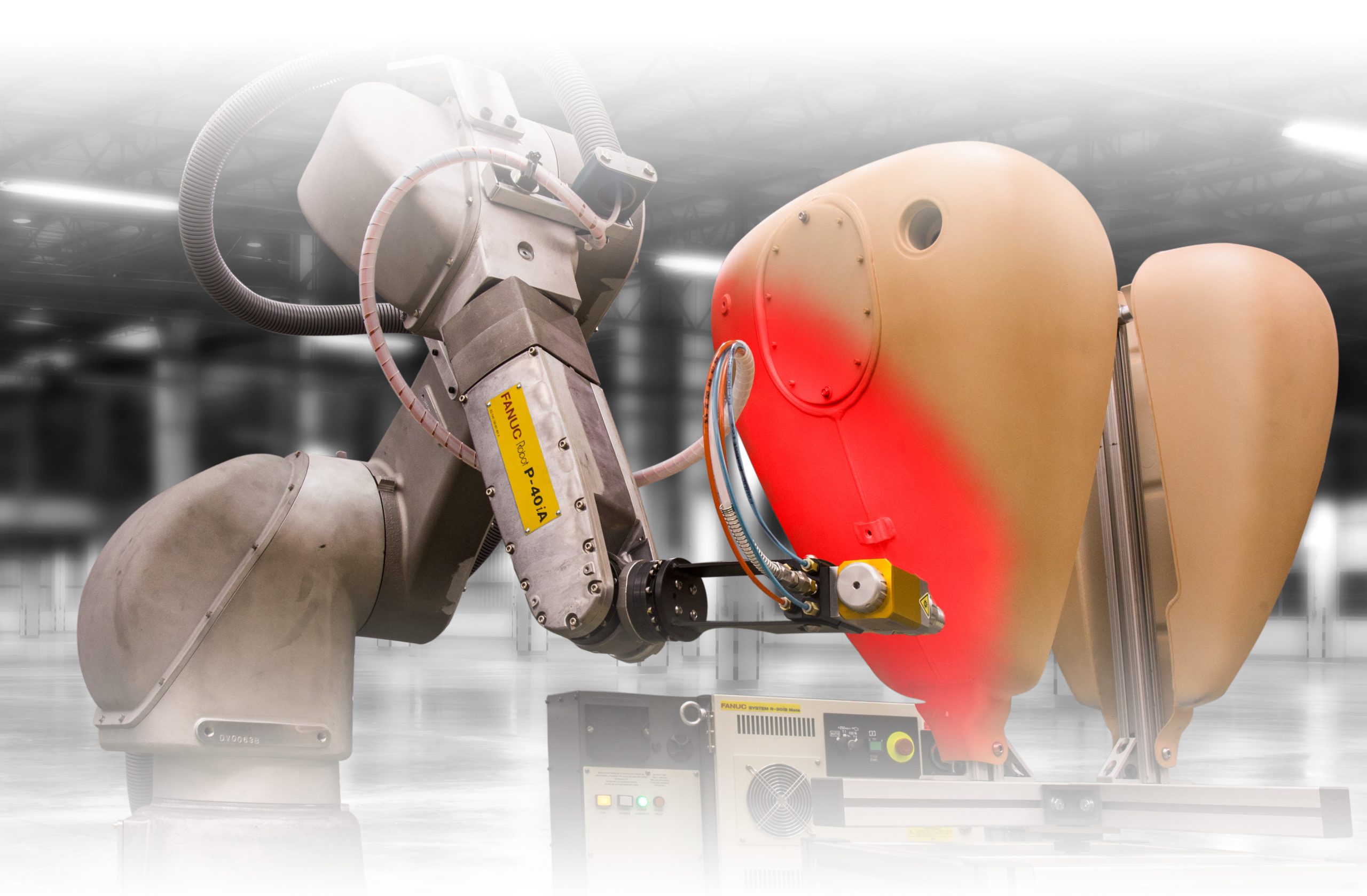

Embracing cutting-edge technology is no longer an option; it’s a necessity. Hence the importance of paint robots in the automotive industry. One revolutionary advancement that has significantly impacted automotive manufacturing is the integration of paint robots. At Automated Solutions Australia (ASA) we are a leading integrator of FANUC paint robots in Australia. In this article, we will explore the role of paint robots in the automotive sector. We look at how ASA is driving innovation with its state-of-the-art solutions.

Streamlining Automotive Painting Processes with Paint Robots for the Automotive Industry

Gone are the days of labor-intensive manual painting processes in automotive manufacturing. With FANUC paint robots, ASA has paved the way for automated and streamlined painting operations. These advanced robots can handle intricate patterns and complex coatings, ensuring consistent quality and flawless finishing across every vehicle they touch. By eliminating human error and reducing material wastage, ASA’s FANUC paint robots help automotive companies achieve unprecedented levels of efficiency and cost-effectiveness.

Enhancing Safety and Worker Well-being with Paint Robots for the Automotive Industry

Safety is paramount in any manufacturing environment, and the automotive industry is no exception. ASA’s integration of FANUC paint robots promotes a safer workplace by removing workers from potentially hazardous painting tasks. By assigning these repetitive and dangerous duties to robots, the risk of exposure to harmful fumes and chemicals is minimised, contributing to improved worker well-being and a healthier work atmosphere.

Precision and Customisation | Paint Robots in the Automotive Industry

ASA’s FANUC paint robots excel in delivering precise and customisable paint applications. These robots can handle various paint types, colours, and textures with unparalleled accuracy, enabling automotive manufacturers to cater to customer preferences effectively.

Sustainable and Eco-Friendly Solutions

In an era where sustainability and environmental consciousness are paramount, ASA’s FANUC paint robots offer a significant advantage. By optimising paint usage and minimising overspray, these robots help automotive manufacturers reduce material wastage, leading to a greener manufacturing process. Additionally, the energy-efficient design of FANUC robots contributes to a reduced carbon footprint, aligning with the automotive industry’s growing commitment to eco-friendly practices.

Comprehensive Support and Services

ASA doesn’t stop at integrating FANUC paint robots into your production line; they provide comprehensive support and services to ensure seamless operations. From initial consultations and system design to installation, training, and ongoing maintenance, ASA’s team of experts is dedicated to empowering your automotive manufacturing with the latest robotic technologies.

In the rapidly evolving automotive industry, staying competitive means embracing innovation. ASA, as the leading integrator of FANUC paint robots in Australia, offers automotive manufacturers the opportunity to revolutionize their painting processes. With increased efficiency, improved safety, precise customization, and eco-friendly practices, ASA’s solutions ensure that your automotive manufacturing reaches new heights. Embrace the future of automotive painting with ASA and experience unparalleled success in the ever-evolving market.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |