Robotic Welders

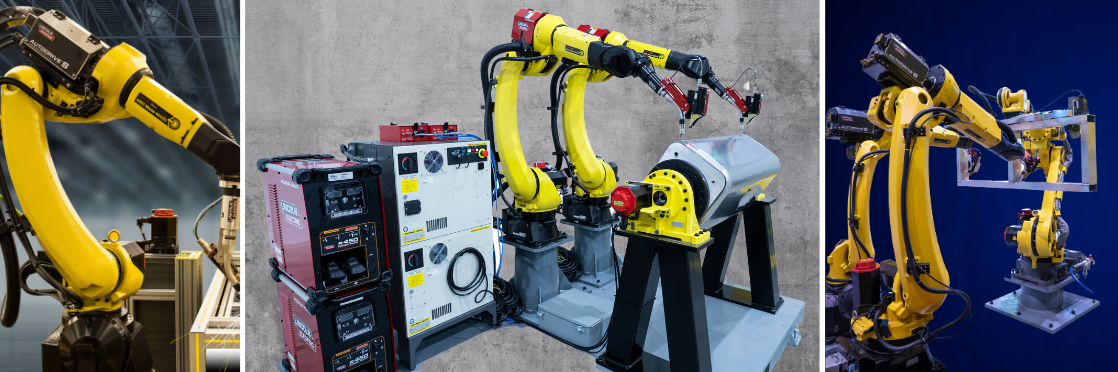

Robotic welders have emerged as game changers for a number of industries. These cutting-edge automated systems have revolutionised robotic welding processes, offering unparalleled precision. Additionally, they offer consistency and speed. Within this article, we’ll explore the incredible potential of robotic welders. Additionally, we’ll delve into how Automated Solutions Australia, specialists in large-scale welding or large-machine welding, are integrating FANUC robots to bring a new era of excellence, thanks to FANUC welding technology.

The Rise of Robotic Welders

Firstly, these advanced machines are designed to perform intricate welding tasks with unmatched accuracy. So gone are the days of manual welding (which often resulted in inconsistencies, higher costs, and potential safety hazards). Consequently, robotic welders have taken over the welding scene, providing manufacturers with a competitive edge, reduced production times, and remarkable cost savings.

The Benefits of Robotic Welders | Robotic Welding in Australia

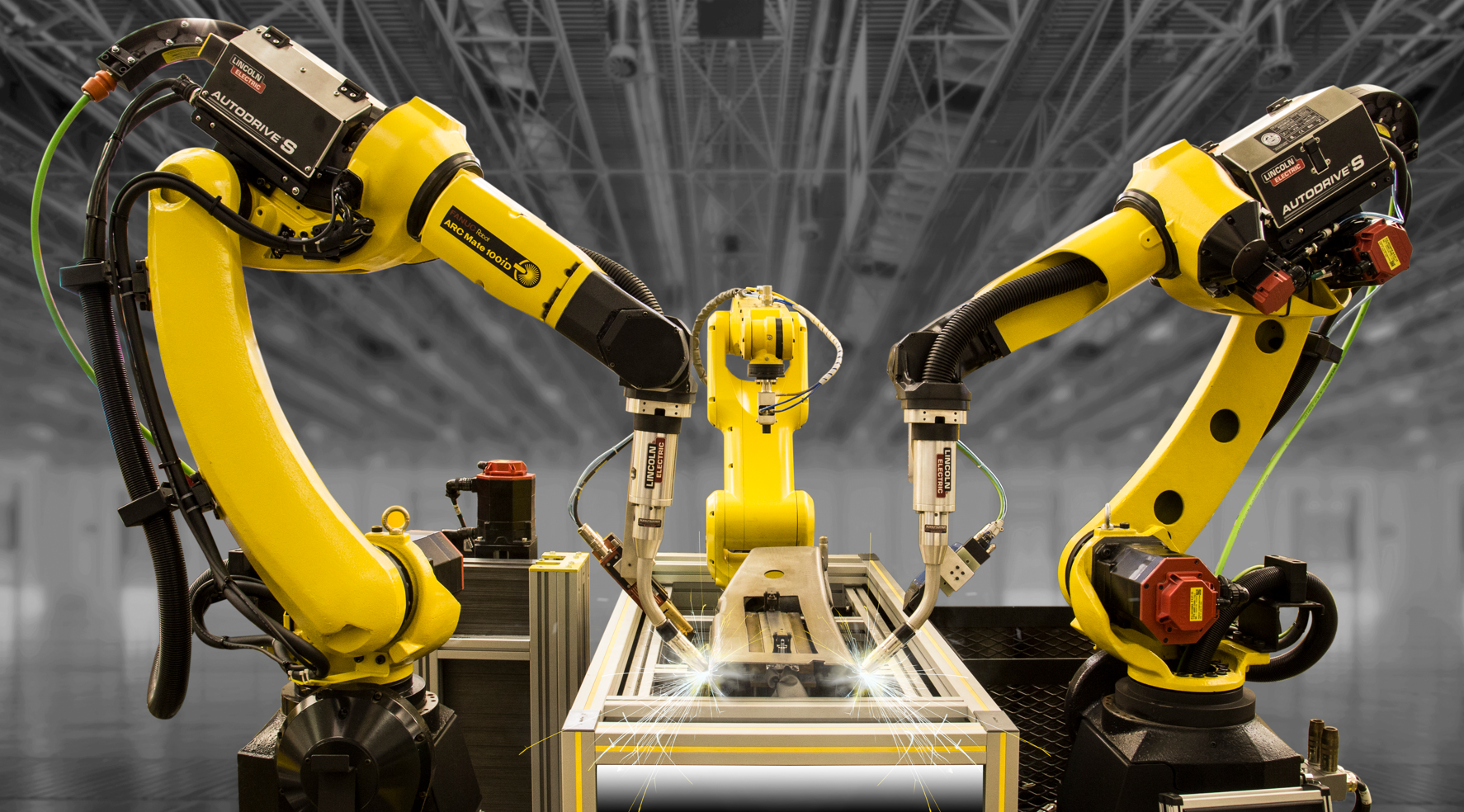

Precision and Consistency – Automated Solutions Australia’s FANUC robotic welders excel in executing precise welds consistently. Moreover, these robots follow pre-programmed paths with utmost accuracy, ensuring uniformity throughout production. As a result, the risk of defects and rework is significantly minimised.

Enhanced Productivity – By integrating FANUC robots, Automated Solutions Australia has optimised their clients’ production lines. Thus substantially increasing productivity. Additionally, these robots work tirelessly, 24/7, without fatigue, significantly reducing cycle times and boosting output.

Cost Efficiency – While the initial investment in robotic welders might seem substantial, the long-term cost savings are especially substantial. Furthermore, with minimal labor requirements and reduced material wastage, manufacturers experience a rapid return on investment (ROI) while enjoying increased profitability.

Workplace Safety – Safety is a top priority in any manufacturing environment. Consequently, with robotic welders performing hazardous welding tasks, the risk of workplace injuries to human workers is greatly reduced. Furthermore, this leads to improved employee morale and a safer work environment.

Robotic Welders | Integrate Australia wide with ASA

Automated Solutions Australia has been at the forefront of industrial automation integration for years. Specialising in FANUC robots, the company has set new benchmarks in delivering tailored automation solutions for various industries. Additionally, we have a team of skilled engineers and technicians, Automated Solutions Australia ensures seamless integration of FANUC robotic welders into existing production lines, allowing clients to unlock the full potential of automation.

Bespoke Solutions for a Wide Array of Industries in Australia

One of the key strengths of Automated Solutions Australia lies in our ability to provide customised robotic welding solutions for a wide range of industries. Specifically, industries that can benefit from robotic welders, include; automotive and aerospace to construction and foundry, FANUC robotic welders can be adapted to meet the unique requirements of each sector. Additionally, the flexibility and versatility of these robots enable manufacturers to stay agile in an ever-evolving market.

Transforming Industry | Robotic Welding

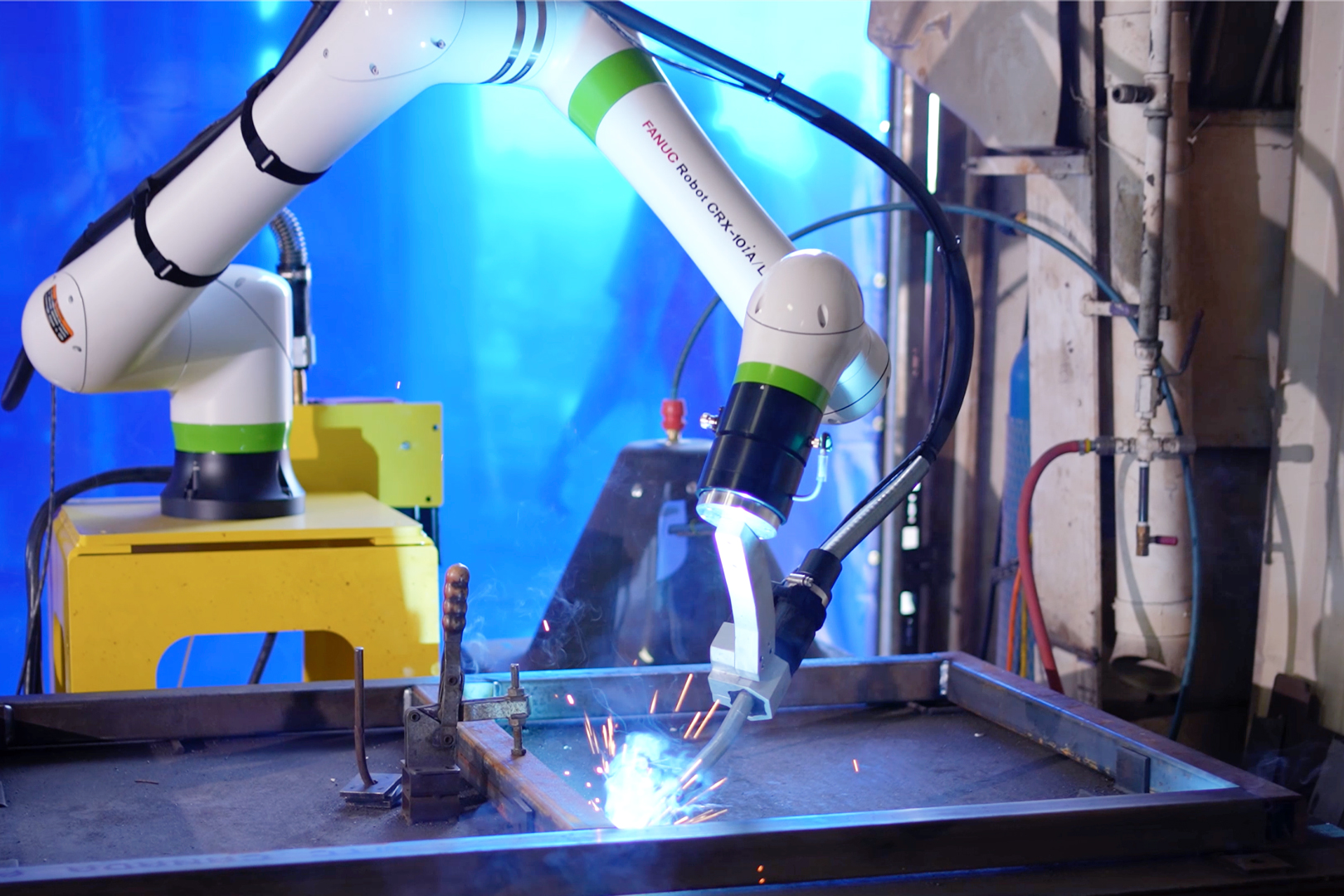

In the welding industry, robotic welding has transformed how welders approach tasks, offering improved precision, consistency, and efficiency. FANUC robots, alongside other industry leaders, provide advanced welding robots designed for various applications such as arc welding, MIG welding, TIG welding, and laser welding. These robots use specialised welding torches to perform automated welding processes, reducing human error and enhancing productivity. With the rise of cobot welding, collaborative robots now work alongside human welders, providing both safety and flexibility. Automated welding systems, like those offered by FANUC and Automated Solutions Australia, are ideal for tasks like spot welding, resistance welding, and robotic welding processes. Industrial robots in these systems are designed to handle repetitive tasks with high precision, making them indispensable in modern manufacturing. Robotic welding solutions allow for efficient control of the welding process, ensuring high-quality results and increased operational efficiency in industries across Australia.

The rise of robotic welders has transformed the manufacturing landscape. The precision, productivity, and cost efficiency offered by these advanced systems are reshaping industries and positioning companies for unparalleled success. So as technology continues to advance, it’s evident that robotic welders will play a pivotal role in defining the future of welding. Embrace the power of robotic welders and unlock the true potential of your manufacturing processes. Contact Automated Solutions Australia today to take your business to new heights.

To learn more about our range of FANUC robotic welders, click here.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |