Robots going where humans cannot go….

We can’t overstate the importance of selecting the right robot for the application to maximise immediate and the long-term gains for your business. In a previous article we considered environmental and ergonomic considerations when choosing the right robot. This article further explores how through careful selection, robots can be installed even in the most extreme environments.

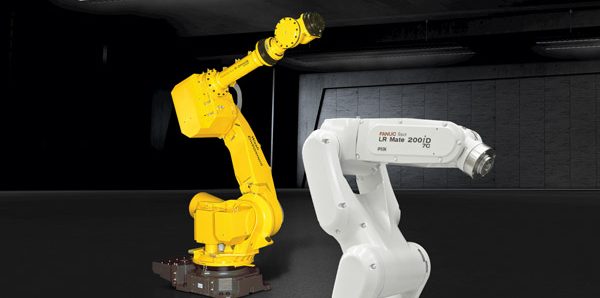

Models in the FANUC foundry robot series are often found in super harsh environments – ‘harsh environment’ is a broad term that can refer to any environment that is hazardous to humans or the robot within it. For example, where there is a high explosive risk, extreme temperatures or pressures, and lack of oxygen or where working conditions are challenging for workers to operate in.

Specialised FANUC robot accessories have the advantage that they provide the flexibility for manufacturers to adapt their robots in harsh conditions. Robots like the M-900iA, a model in the FANUC foundry line, are designed to work in harsh environments without fatigue, increasing productivity and saving money for the manufacturer.

FANUC foundry robots increase safety in the workplace by keeping human workers out of hazardous working conditions.

Featuring motor covers, waterproof connectors, cable covers, coatings and stainless steel bolts and washers in exposed areas, the FANUC SDLP package improves your robots’ resistance to harsh, dusty or wash environments. The package also features IP56 protection on the main body and IP67 protection on the J3 arm and wrist unit.

The IP Code, or Ingress Protection Code, classifies and rates the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water.

FANUC’s M-710iC/50 SE FoundryPRO robot is IP67 protected for operation in the harshest environments. The entire robot is coated with a special epoxy, and the wrist has protective covers to withstand high-pressure washing. In addition, the base of the robot purges air to avoid vapor entrance. FANUC has also incorporated coated bolts and double oil seals at the joints, making this a truly waterproof robot.

Robots now come in numerous forms and sizes, each possessing vastly different functions and intended for deployment in very different circumstances. Robots can be installed in harsh environments where health and environmental risks are a factor, and where an improvement is an absolute necessity, so there’s no reason to hesitate to go with robots where humans cannot go.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |