Embracing Welding Automation for Enhanced Productivity and Efficiency

Across the industrial landscape, a significant transformation is underway. In turn, companies are increasingly investing in robotics and automation to maximise their productivity and efficiency in manufacturing processes. One area experiencing a technological revolution is welding. Therefore, with thanks to robotics, welding automation has become a game-changer, promising unparalleled speed, precision, and consistency.

Welding Automation for Advanced Robotics in Australia

Welding automation leverages advanced robotics to significantly enhance the production and quality of welds. By automating the welding process, companies can achieve a faster production rate, increased precision, and superior quality, while additionally minimising the potential for errors and inconsistent welds (that are more likely with manual operations).

The integration of welding robots into the manufacturing process is not just about speed; it’s about flawless precision and smooth operation through pre-programmed paths. Additionally, these computer-based systems, equipped with sensors, can follow seams and adjust welding parameters in real time, ensuring high-quality welds with minimal oversight.

The Scope of Welding Automation

Welding automation spans from partial automation, where certain steps are robotised, to total automation, where the entire operation is performed without manual intervention. This flexibility allows for the application of automation in various manufacturing processes, with equipment designed for both fixed and flexible automation.

This includes for:

Robotic MIG and TIG welding

Plasma and Laser cutting

Spot Welding

Adaptive control and joint finding

Seam tracking

Flexible manufacturing systems

Process and robotic simulation

The adoption of robotically automated systems offers numerous benefits, including increased productivity, consistent weld quality, predictable production rates, and reduced costs.

Integrating Welding Automation with ASA and FANUC

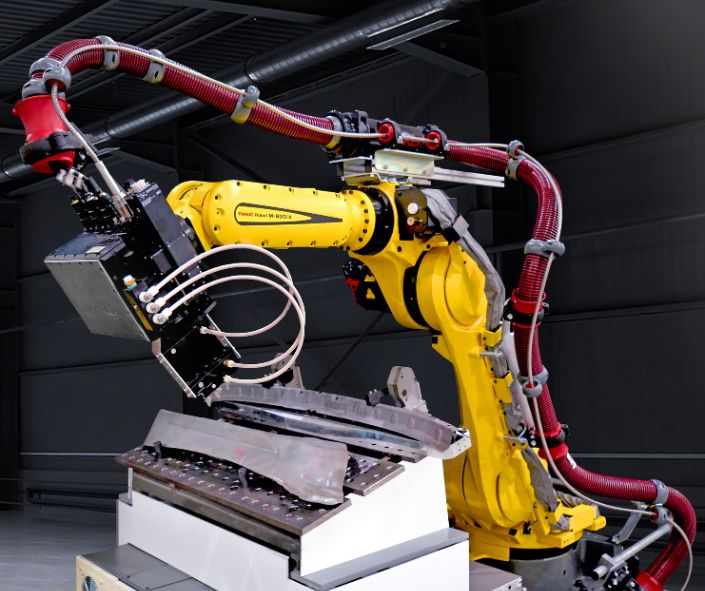

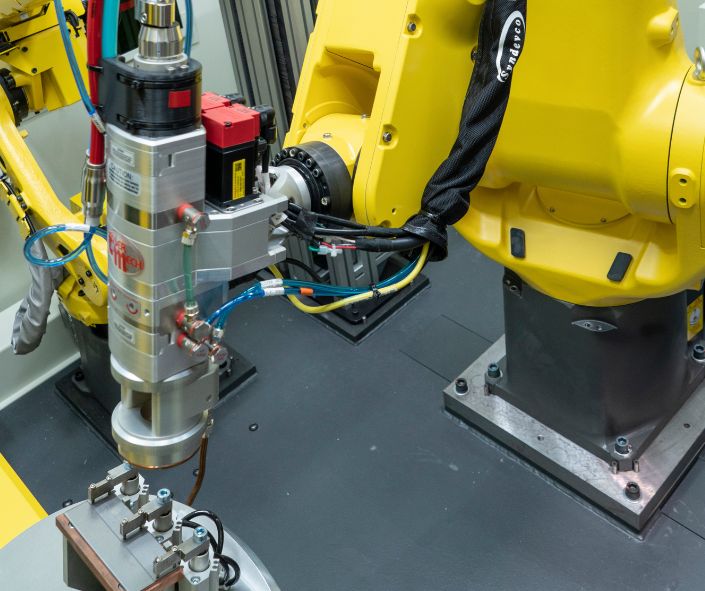

Choosing the right partner for welding automation is crucial. Automated Solutions Australia (ASA) offer a comprehensive range of FANUC robots, renowned for their reliability and versatility in arc, spot, and laser welding. FANUC’s extensive selection, with a payload and reach range of 7 kg to 25 kg and from 911 mm to 3123 mm, ensure there’s a robot for every task, whether it’s MIG or TIG welding, plasma cutting, or more specialised applications.

The FANUC ARC Mate series, is designed specifically for industrial arc welding applications, offering a range of payloads and sizes to meet diverse needs. Similarly, spot welding robots from FANUC deliver unmatched weld quality through precision and repeatability.

For those looking for collaborative solutions, FANUC’s CR-15iA and CR-7iA/L collaborative robots are based on the industry-leading ARC Mate series. These cobots offer an easy-to-program interface, allowing for basic to advanced applications, and come equipped with FANUC’s sophisticated capabilities, such as weaving and seam tracking.

Why Choose Automated Solutions Australia (ASA)?

Automated Solutions Australia is at the forefront of integrating FANUC industrial and collaborative robots. With a team of specialists in FANUC robot integration, ASA supports Australian businesses in achieving their automation objectives, enhancing their competitiveness on the global stage.

Whether you’re exploring welding automation for the first time or looking to expand your existing capabilities, ASA and FANUC offer the expertise and technology to transform your manufacturing process. Contact Automated Solutions Australia today to discover how welding automation can revolutionise your production, ensuring efficiency, quality, and competitiveness in a rapidly evolving industrial world.

By embracing welding automation technologies, companies can not only meet the demands of modern manufacturing but also pave the way for future innovations, ensuring a competitive edge within the global market.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |