Automation Technology | The Heart of Modern Industry

Automation technology stands at the heart of modern industry, streamlining processes and reducing human intervention. As the robotics field gains momentum, Automated Solutions Australia, a leading automation technology company, pioneers the way in harnessing the immense potential of automation technology. Specifically focusing on automating processes by integrating world-renowned FANUC robots.

The Origins of Automation Technology

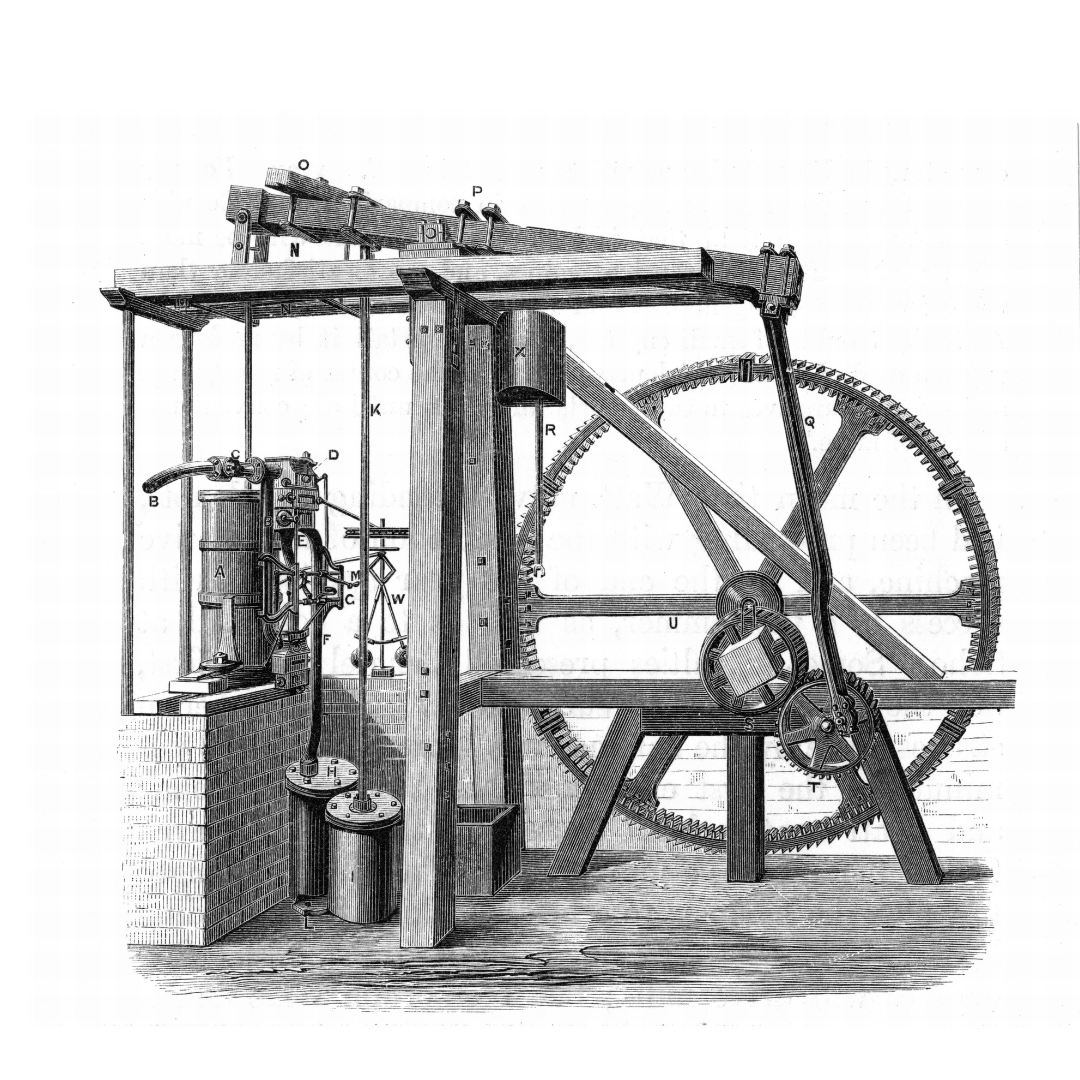

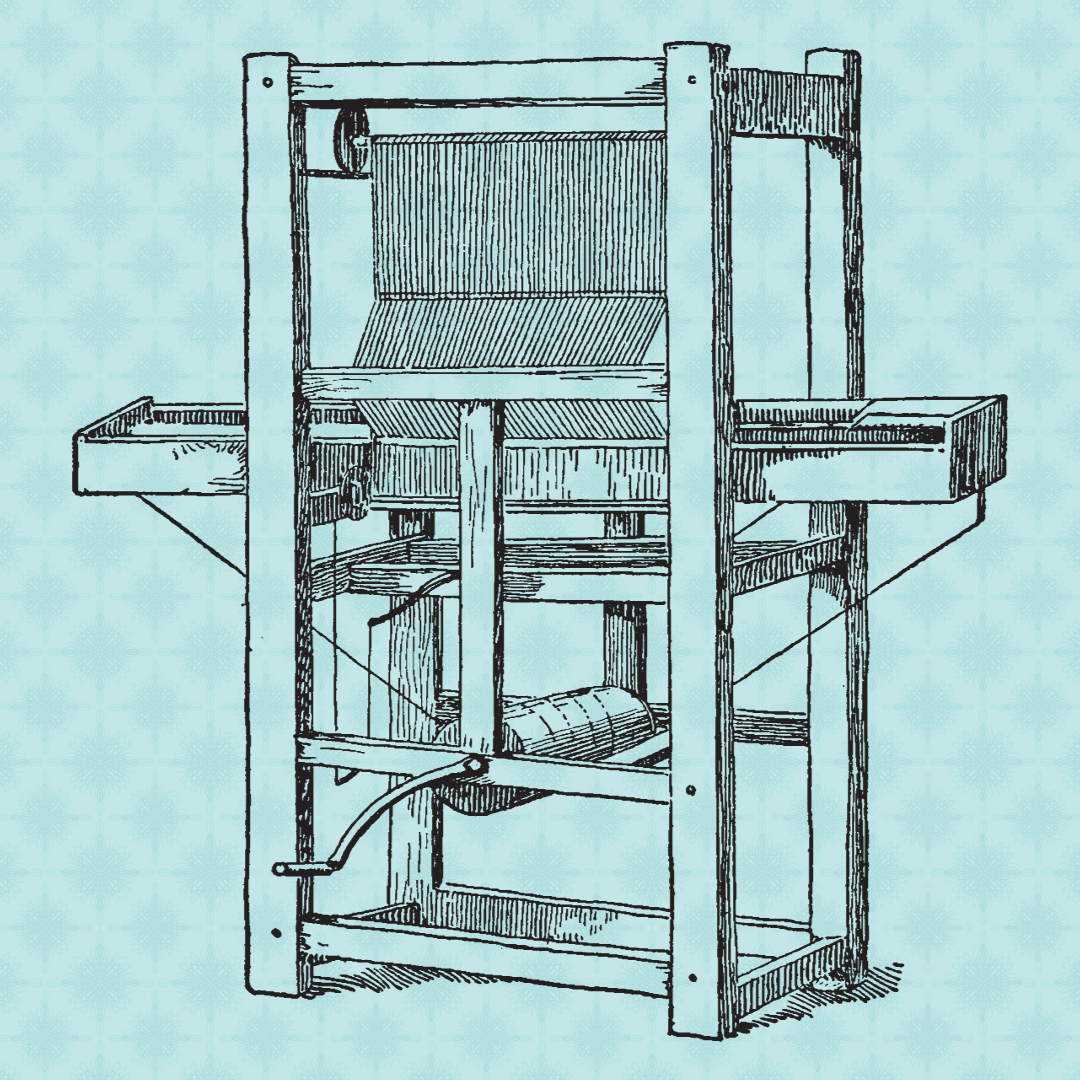

The history of automation can be dated back to the 18th century. Edmond Cartwright’s invention of the fully mechanised loom in 1785 heralded the textile industry’s evolution, a significant step forward in the industrialisation of the weaving process. Following closely, James Watt’s innovations in 1788 paved the way for modern control technology whereby he made a significant innovation related to the steam engine: he introduced the “centrifugal governor,” a device to regulate the speed of the engine.

What is Automation Technology?

Automation technology encompasses the myriad of processes and equipment that allows things to operate with minimal human intervention. Additionally, this vast domain aims to optimise efficiency and reduce errors in various systems. Thus, the more advanced the technology, the lesser the need for human control.

Benefits of Embracing Automation Technology

Safety & Efficiency: Automation relieves humans from undertaking hazardous or strenuous tasks. Machines can tirelessly handle repetitive tasks, ensuring consistent quality.

High Performance: Automated systems can operate around the clock, significantly outpacing manual processes.

Cost-Effective: Automation plays a pivotal role in reducing personnel costs and enhancing the quality of products.

Realms of Application

Automation technology permeates nearly every aspect of modern life:

Household Applications: From dishwashers to smart homes, automation has revolutionised domestic life.

Automotive Industry: Features like anti-lock braking systems and automatic gearboxes have transformed driving experiences.

Industrial Production: Particularly, in production environments, automation is indispensable. Industries ranging from automotive, electrical, and aerospace have embedded automation deeply into their operations.

Structure & Functionality | Automation Technolgy

An automated system utilises advanced sensors for precise data collection. An automatation system executes control commands with unmatched accuracy. Thus ensuring a seamless flow of information, and guaranteeing optimal performance. At ASA we integrate FANUC robots to ensure a consistent, reliable, and efficient workflow for all manufacturing processes.

Human Interaction in Automation Technology

The human-machine interface (HMI) empowers users to monitor and interact with automation systems, ensuring oversight and intervention when necessary. This interface is vital for understanding and supervising system processes.

Ensuring Quality and Safety with Automation Technology

Choosing high-quality components is paramount in automation technology. Collaborating with trusted providers like Automated Solutions Australia guarantees you top-tier robotic systems,. Safety is non-negotiable. It’s vital to ensure safe and reliable operation, thus FANUC robots are inherently safe .

The Latest in Automation Technology with ASA

FANUC is a leading manufacturer of industrial robots and has a wide range of robots that are employed in various sectors for automation. At ASA we exclusively integrate the FANUC range, as we believe they are the premier robots on the global stage. Here are some examples of tasks and industries where FANUC robots play a significant role in automation:

Material Handling and Pick & Place: Transferring parts, products, or other materials from one place to another, especially in manufacturing processes.

Welding: FANUC robots are used for arc welding and spot welding in automotive and other manufacturing sectors.

Assembly: Robots assemble parts, especially in electronics and automotive industries, ensuring precision and speed.

Palletising: Organising and stacking products on pallets for shipment.

Machine Tending: Loading and unloading parts in and out of machines, like CNC machines.

Painting: Providing consistent application of paint on cars, appliances, and more.

Cutting & Trimming: Tasks like waterjet cutting, laser cutting, and trimming of plastic and metal parts.

Dispensing: Robots handle precise application of glue, sealants, or other materials on parts.

Automation Technology Applications | Continued

Packaging: FANUC robots handle products, pack them into boxes, and then seal the boxes.

Food & Beverage: They handle food processing tasks, such as sorting, packaging, and even butchering.

Pharmaceuticals: Handling medication, packaging, and other tasks where precision and hygiene are paramount.

Cleanroom Applications: Robots designed for environments that require a high level of cleanliness, like semiconductor manufacturing.

Laboratory Automation: Robots help with tasks like sample handling, testing, and other repetitive laboratory tasks.

Deburring & Polishing: Robots are used to remove burrs from metal parts and polish them.

Vision Inspection: With integrated vision systems, robots can inspect products for defects.

Grinding: Robots can be equipped with grinding tools to automate the process of removing excess material from workpieces.

The adaptability of FANUC robots means they can be customised for a vast range of tasks across different industries.

In the age of technological advancements, automation technology, especially in the field of robotics automation, promises a future of efficiency, safety, and innovation. As an industry frontrunner, Automated Solutions Australia remains committed to unlocking the full potential of automation technology, leading the way in automating FANUC robots and delivering tomorrow’s solutions, today.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |