Benefits of a Welding Cobot

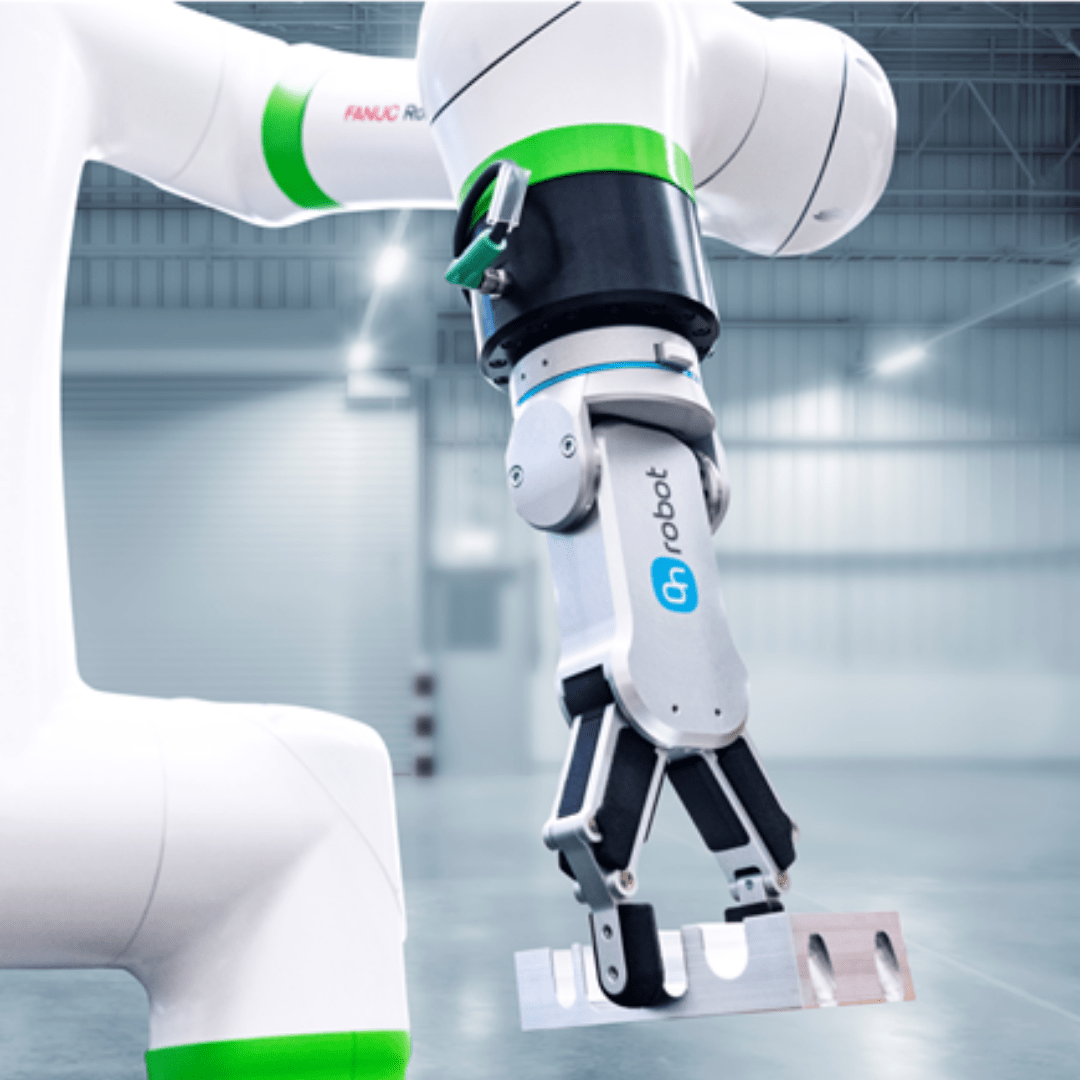

Collaborative welding robots are industrial robots that can be used for cobot welding, with safety-rated features that reduce or eliminate the need for traditional safeguarding. Additionally, a welding cobot offers ergonomic benefits and space-saving advantages, potentially reducing the cost of fencing and other safety measures.

Collaborative robots perform applications in various manufacturing processes, including arc, mig, and tig welding, assembly, machine tending, pick and place, packaging, palletising, and more.

A Collaborative Solution

Are you seeking the ultimate welding automation solution? Look no further than Automated Solutions Australia, and cobot welding. We are your trusted partner for integrating cutting-edge FANUC Cobots for welding automation. Our Cobot Welding integration offers a seamless blend of innovation and efficiency. So we are revolutionising the way you approach welding in your manufacturing operation.

Why Choose FANUC Welding Cobots for Cobot Welding?

Firstly, their simplicity. They are made with easy setup and programming in mind.

Integration with welding processes

Compact design, saving floor space

Ideal for both small and large operations

Lastly, you can’t look past their quick redeployment, for ultimate flexibility

Unlock Welding Excellence with Cobot Welding

FANUC stands at the forefront of robotic technology, and their arc welding cobots are no exception. Therefore with the industry’s most extensive range of collaborative robot models and an intuitive programming interface, these cobots are tailored to suit the specific needs of your manufacturing process. And when it comes to cobot welding, these cobots stand in a class of their own.

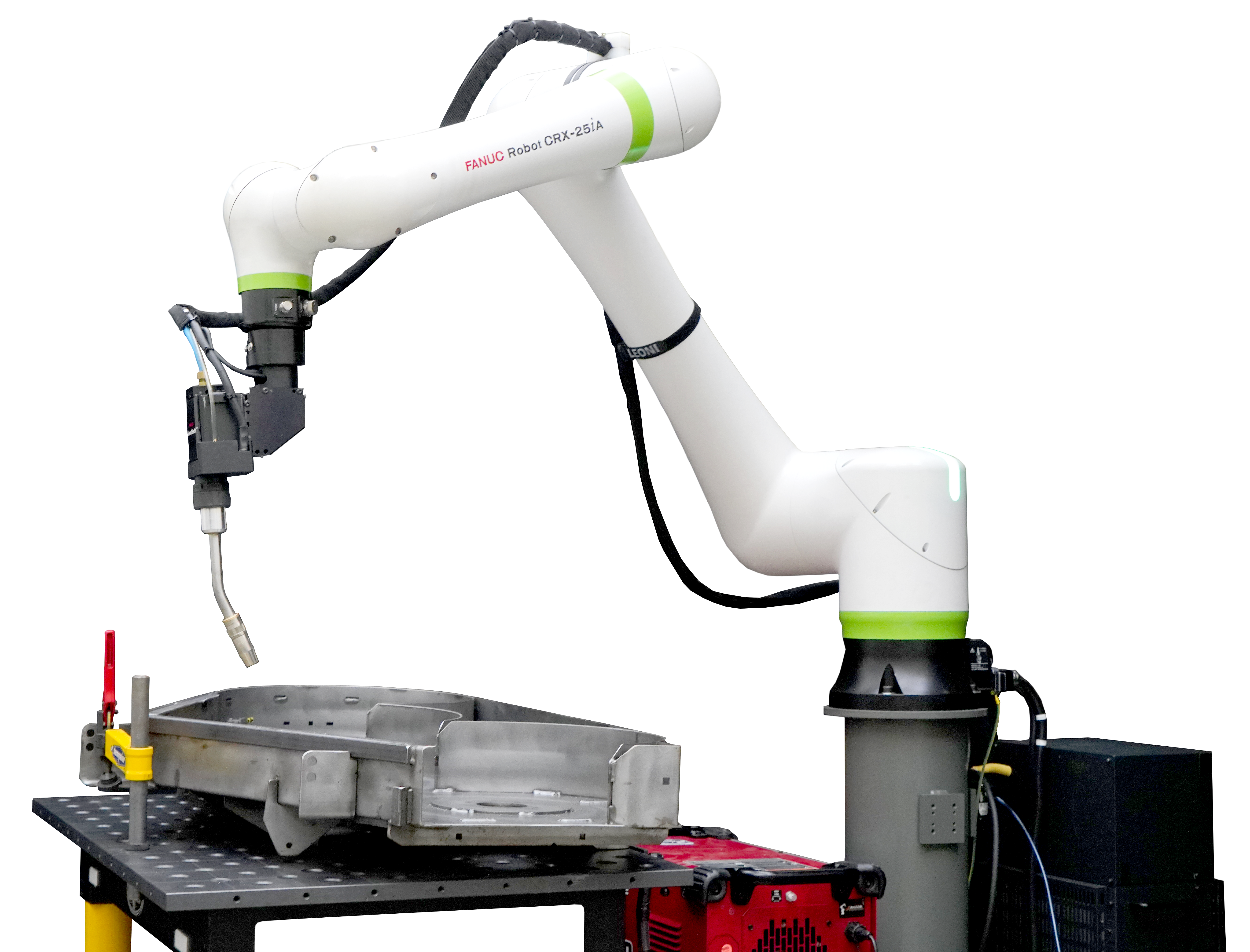

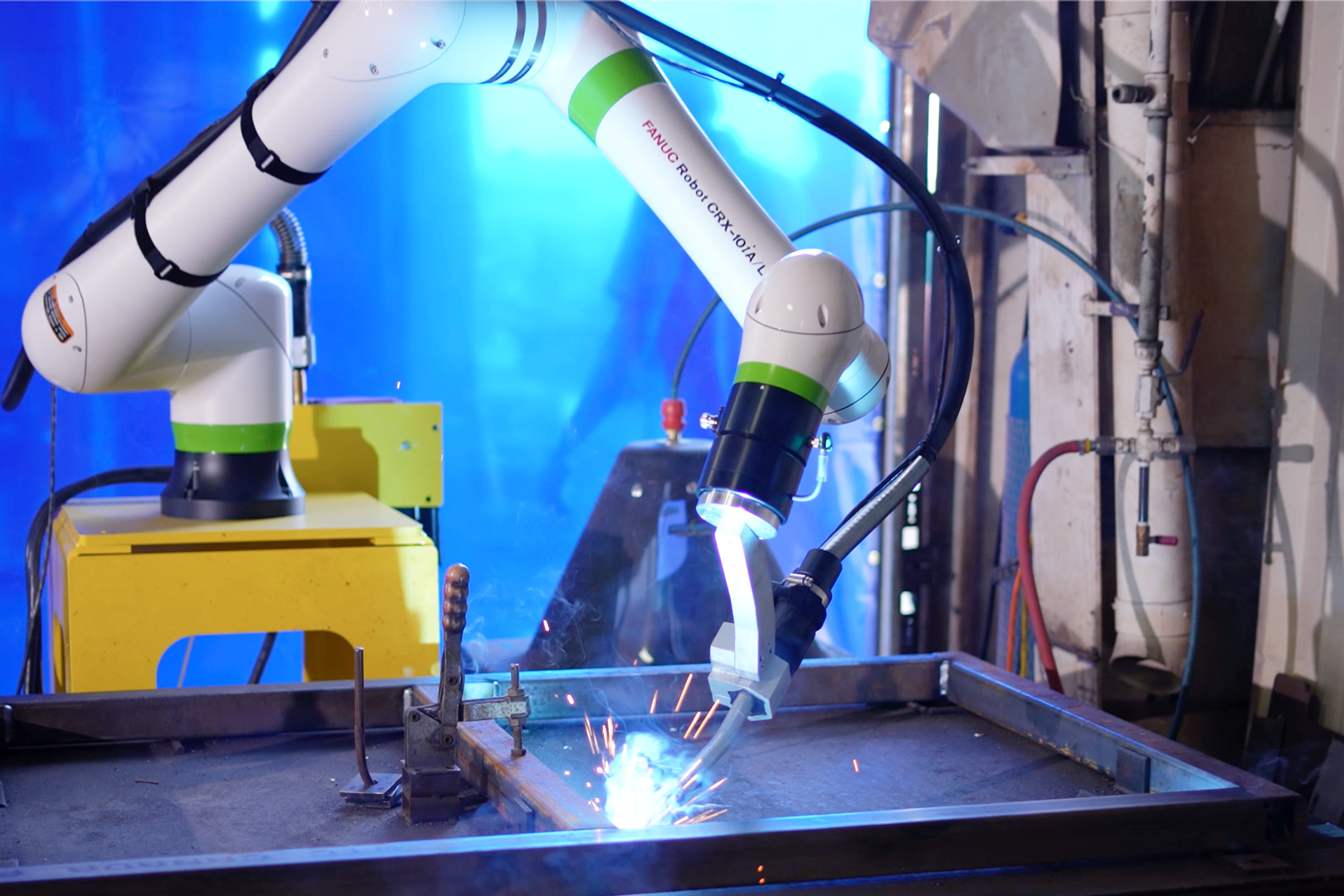

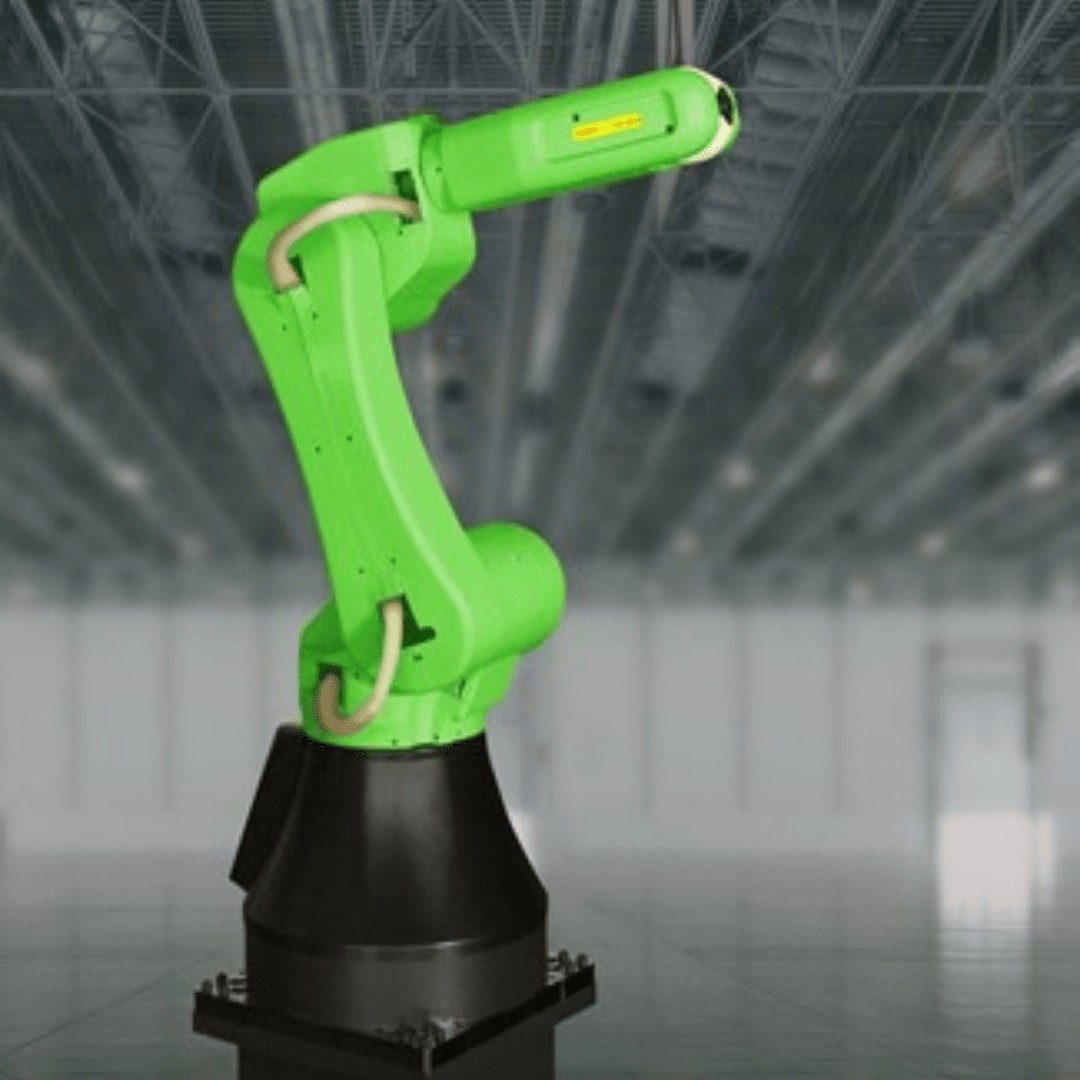

FANUC CRX Series and CR Series Cobots

FANUC brings you the latest in cobot welding technology. The CRX Series and green CR Series Cobots deliver the same exceptional performance and reliability that FANUC ARC Mate robots are renowned for. In addition, these robots are equipped with built-in sensors, ensuring a safe working environment alongside human operators, all without the need for costly guarding.

Seamless Integration and Ease of Use

Welding automation has never been easier, even for those new to robotics. Our advanced cobot welding technology, backed by expert knowledge, empowers you to automate complex welding projects with confidence. By partnering with FANUC, manufacturers gain access to arc welding solutions that enhance their competitive edge in the global market.

Explore FANUC‘s Arc Cobot Welding Models

CRX-10iA Collaborative Robot

Axes: 6

Payload: 10 kg

Reach: 1249 mm

CRX-10iA/L Collaborative Robot

Axes: 6

Payload: 10 kg

Reach: 1418 mm

CRX-20iA/L Collaborative Robot

Axes: 6

Payload: 20 kg

Reach: 1418 mm

CRX-25iA Collaborative Robot

Axes: 6

Payload: 25-30 kg

Reach: 1756-1889 mm

Advanced Programming Made Easy with ASA

With FANUC’s CRX Cobot, programming becomes a breeze. The drag-and-drop programming features and user-friendly teach pendant interface make it accessible even for beginners.

FANUC Cobots offer a glimpse into the future of welding automation. Their ability to effortlessly integrate with various weld packages ensures quick and efficient welding power source interface. FANUC robots excel in handling diverse arc welding applications and cobot welding is no exception. Their robust design allows for submerged arc welding, tandem torches, and multiple welding processes on the same robot. Enjoy the benefits of exceptional payload capability, even for additional equipment like sensors and grippers. To integrate a FANUC cobot into your manufacturing processes, call ASA today, on 1800 ROBOTS, or email us at sales@automatedsolutions.com.au

For more on Collaborative Robots, click here.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |