The FANUC LR Mate Robot Series of human-arm-sized robots is the most compact option for quickly manipulating and processing up to 14 kg items in a variety of industries.

FANUC LR Mate Series Robots – Tabletop Robot with a Small Payload

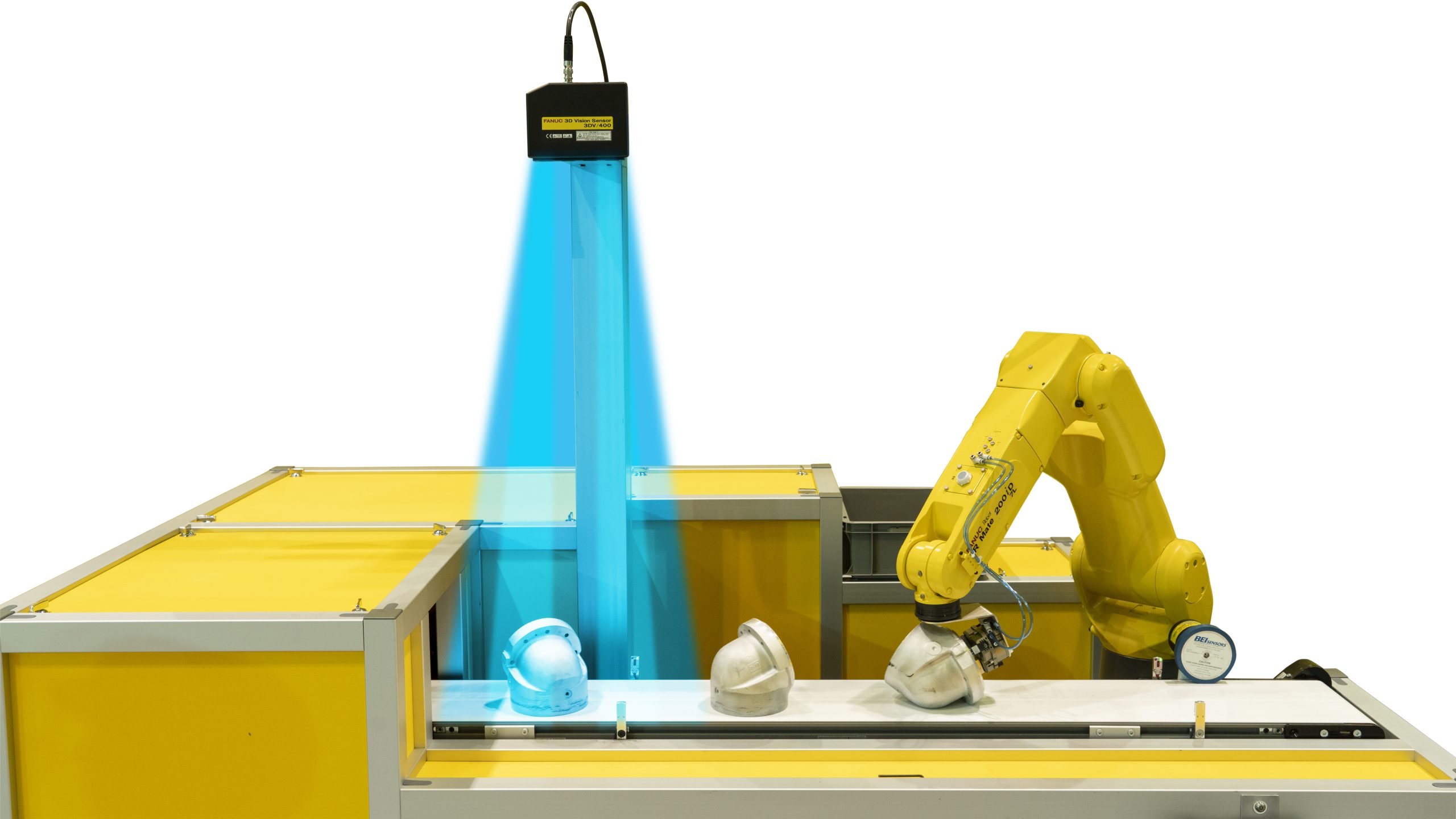

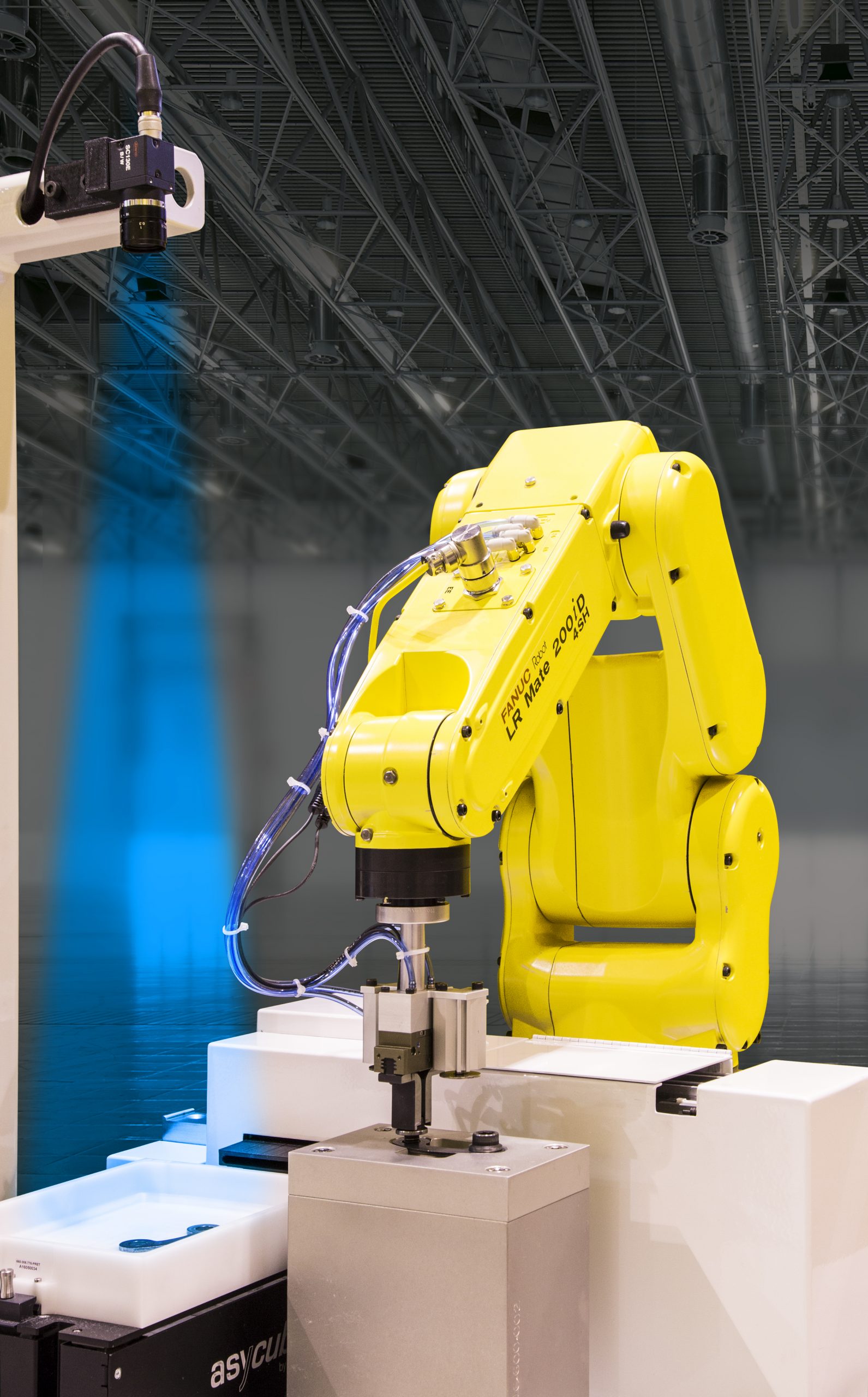

The FANUC LR Mate Series Robots range from a maximum payload of 4 kg to 14 kg. Furthermore they vary in reach from 550 mm on the short arm variant (/S), to 717 mm on the standard model. Comparatively, they can reach 919 mm on the long arm variant (/L). While the series is available in a variety of types. Explicitly speaking there are clean room (/C), high speed (/H) and wash-proof (/WP) variants. In addition they come with varying reaches and wrist speeds to fit your specific needs. Generally these tabletop robots with modest payloads may be outfitted with a variety of intelligence characteristics. Specifically including robot vision and force sensing. Further enhancing precision and productivity.

FANUC LR Mate Series Robots are Adaptable, Strong and Fast.

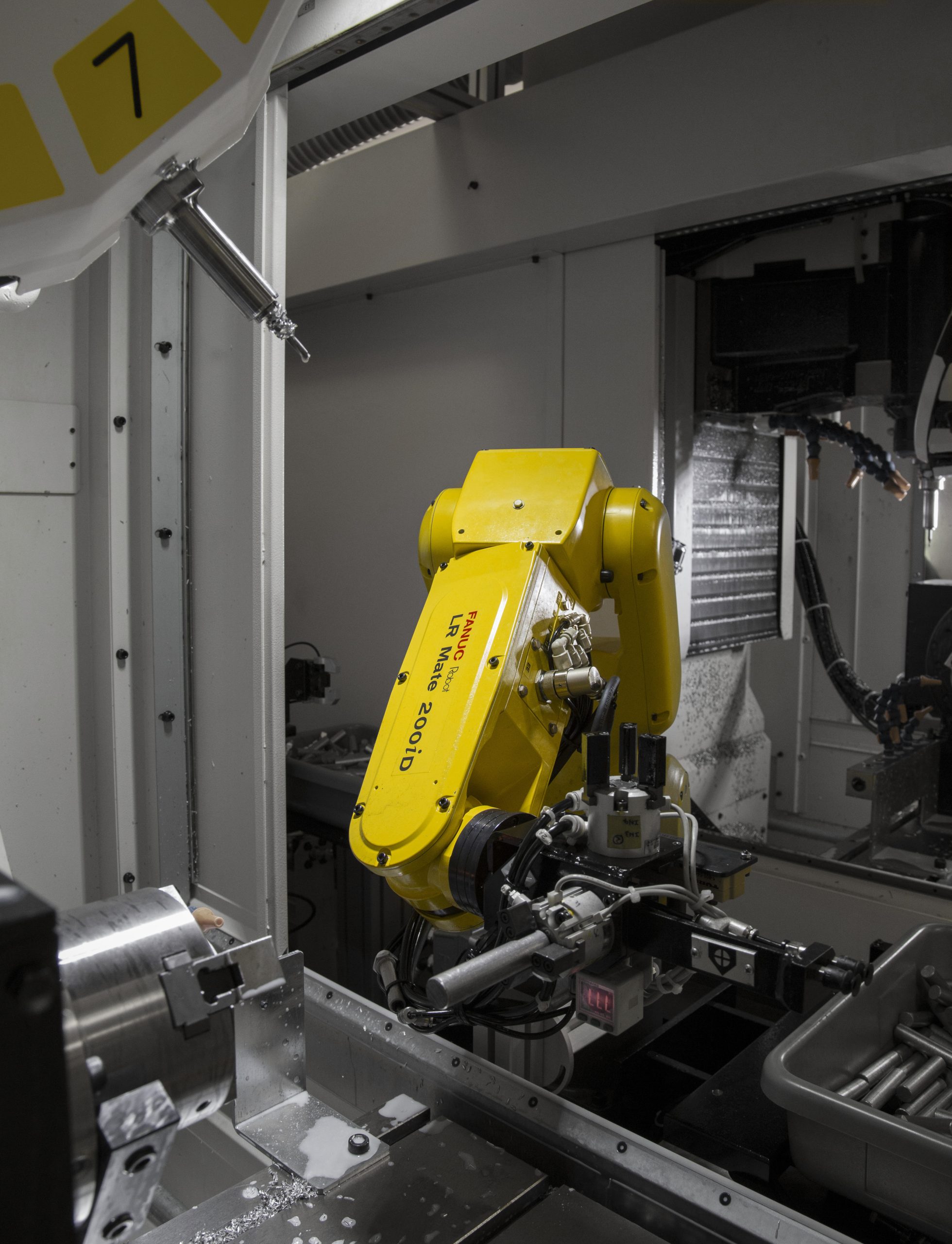

Regardless of size, the FANUC LR Mate Series Robots easily adapt to any circumstance.Surprisingly mounting options for this small, multifunctional robot include floor, ceiling, wall, and angle. In addition you can even integrate it directly into your machine tool. Because of its compact design and sealed mechanical units (IP67). Consequently, the possibilities are endless, as the mounting options allow for more flexible cell designs. Thus they allow for a more robust work envelope, and the ability to run multiple robots in close proximity.

Models from the series are available with a maximum reach of 911 mm on the long arm (/L) variant. Altogether they allow for a maximum payload capacity of 14 kg on the /14L variant, and wrist speeds of up to 1500 °/sec on the /H high speed variant. Although these features mean that FANUC LR Mate Series Robots have increased flexibility to ensure that cycle times are minimised, the design of the unit additionally promotes connectors on the J3 axis for system adaptability, internal cable routing, performance and dependability.

FANUC LR Mate Series Robots increase Throughput and Flip Over Capable

This FANUC series robust servo motors and very stiff arm enable fast acceleration and quick cycle times. Thus resulting in increased production rates for users. So robot connections supplied on the bottom of axis 1 guarantee minimum interference with peripheral equipmen. Therefore the FANUC LR Mate Series Robots are designed to save time.

With unique flip over capabilities the FANUC LR Mate Series Robots are the answer to a number of problems. Firstly shorter cycle times, further flexible cell designs, a complete work envelope and inverted mounting. Lastly the flexibility to operate many robots in close proximity.

ASA is your ideal FANUC collaborative robot and industrial robot integrator. Furthermore, our team at ASA are FANUC robot specialists, from concept to system designs, installations, programming and support. Evidently Automated Solutions Australia (ASA) thrive on helping Australian business of all sizes achieve their automation goals. Additionally this helps Australian companies to compete on the world stage. Undoubtedly for FANUC integration, Automated Solutions Australia are your Australian industry leading experts. So contact us today!

Presently our communication lines are open 24/7, ready to assist you in any way we can.

For the latest News on the LR Mate Series of robots, click here.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |