Machine Tending Robots – a Game-Changer, Revolutionising the Manufacturing Process

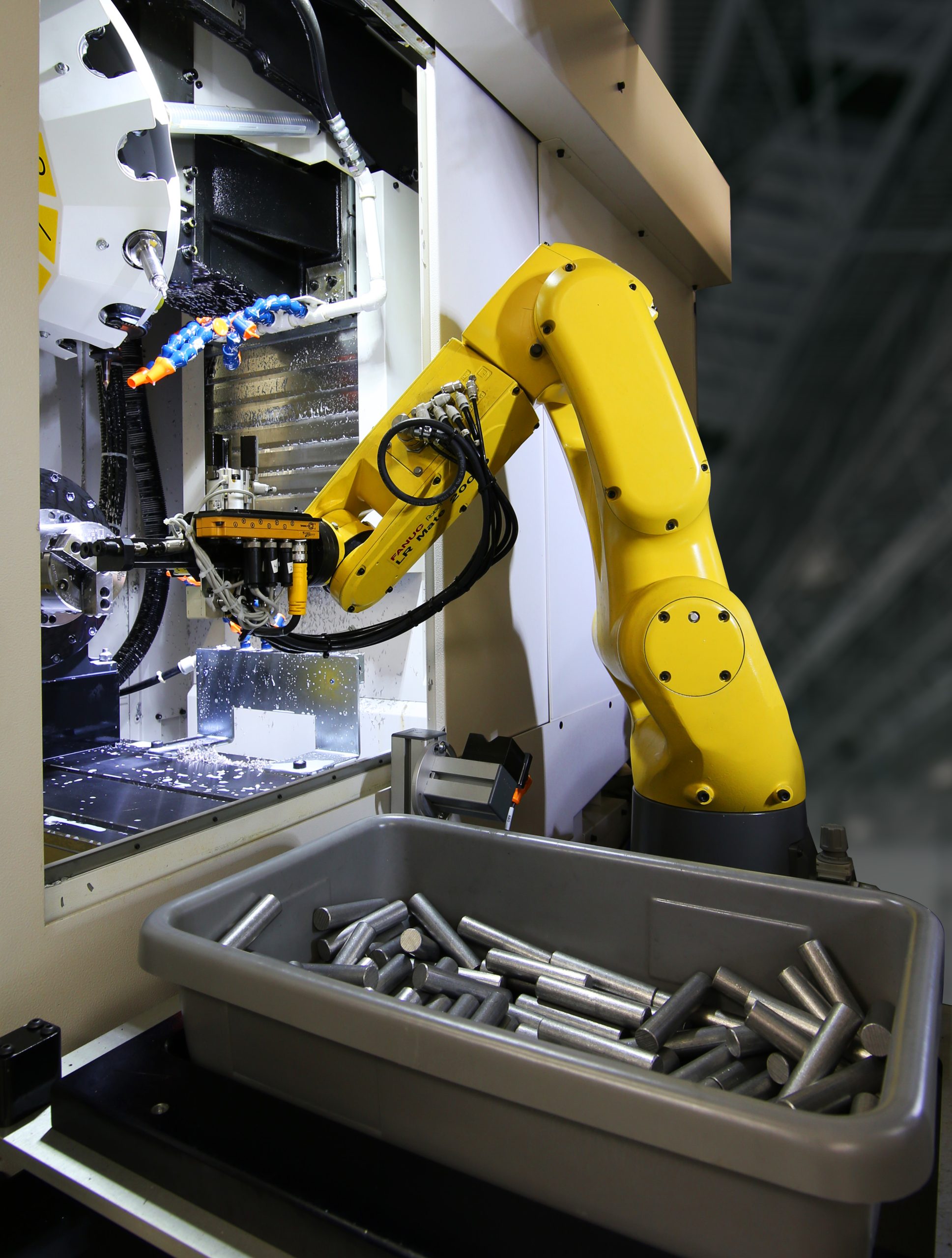

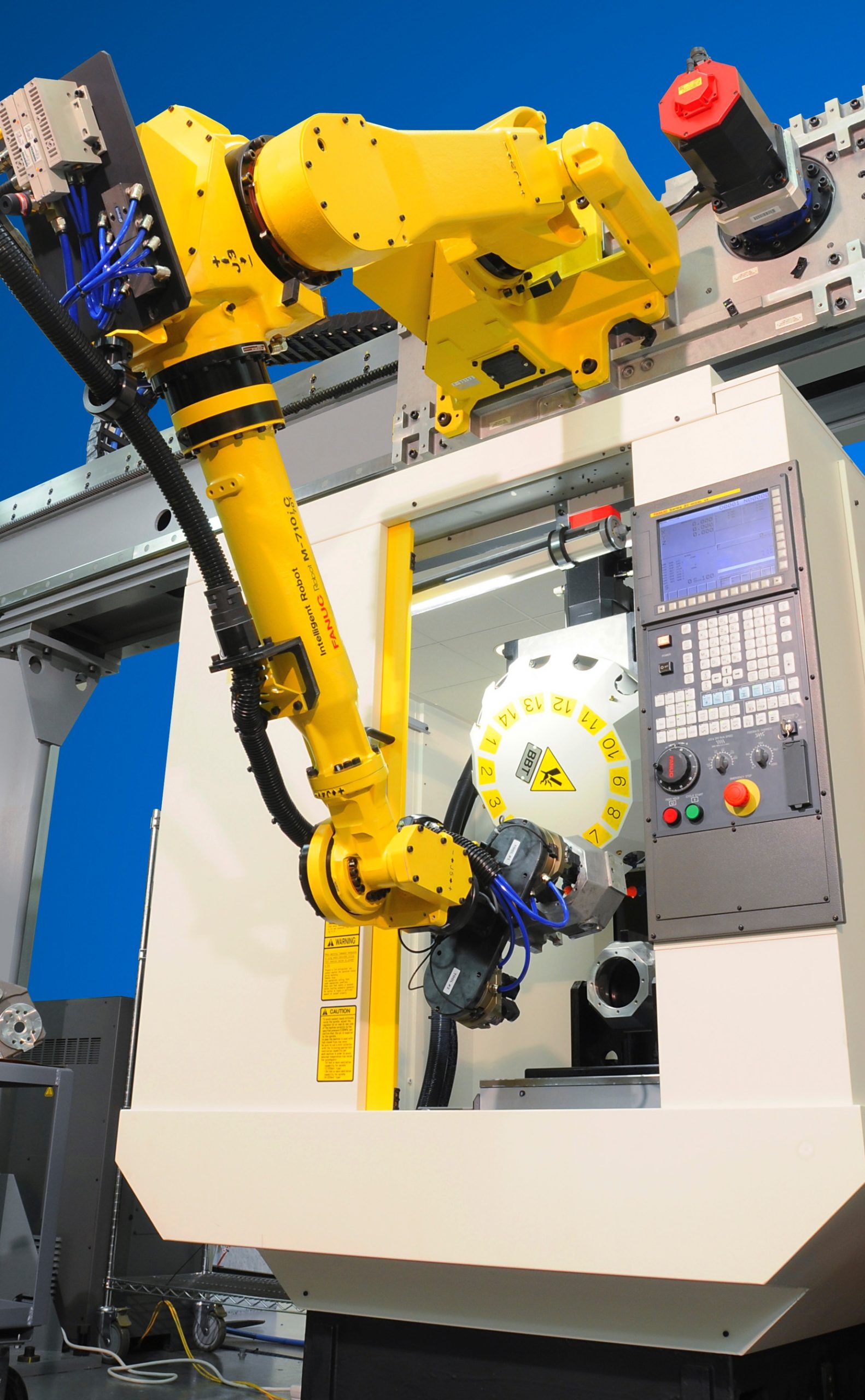

In today’s fast-paced aftermarket automotive industry, manufacturers are constantly seeking innovative solutions to boost efficiency and stay ahead of the competition. Machine tending robots within the aftermarket automotive industry have emerged as a game-changer, revolutionising the manufacturing process. At ASA, we take automation to the next level by integrating FANUC machine-tending robots, providing the automotive sector with a winning edge in quality, productivity, and cost-effectiveness.

Unleashing Precision and Consistency with Machine Tending Robots in the Aftermarket Automotive Industry

Accuracy and precision are paramount in the aftermarket automotive industry. FANUC machine tending robots excel in repetitive tasks, ensuring consistent and flawless machining operations. By eliminating human errors, these robots deliver a level of precision that significantly enhances the quality of aftermarket automotive components, thus reducing defects and minimising waste.

Optimising Production Cycles

Time is money, and in aftermarket automotive manufacturing, every second counts. ASA’s FANUC machine tending robots optimise production cycles by streamlining the material handling process. They work tirelessly, 24/7, eliminating downtime between operations and increasing overall throughput. This results in faster turnaround times and accelerated production schedules, enabling automotive companies to meet tight deadlines and tackle market demands effectively.

Seamless Integration and Adaptability with Machine Tending Robots in the Aftermarket Automotive Industry

ASA’s expertise lies in seamlessly integrating FANUC machine tending robots into existing machining centers. These robots are designed to be versatile and adaptable, making them an ideal fit for diverse production environments. Whether it’s CNC milling, turning, or grinding, FANUC robots can be easily programmed to handle a variety of tasks. Moreover, they effortlessly adapt to changing production requirements, ensuring your manufacturing processes remain agile and efficient.

Elevating Workplace Safety

Aftermarket automotive manufacturing can be physically demanding and hazardous for human workers. ASA’s FANUC machine tending robots take on these arduous tasks, reducing the risk of workplace accidents and enhancing employee safety. By allowing robots to handle dangerous operations, human workers can be redeployed to more strategic roles that require creativity and critical thinking, further optimizing the workforce.

In the ever-evolving landscape of aftermarket automotive manufacturing, ASA‘s integration of FANUC machine tending robots stands as a testament to our commitment to driving efficiency, quality, and innovation. With their unmatched precision, seamless integration, and enhanced workplace safety, these robots are transforming the automotive industry, enabling companies to achieve new levels of productivity and excellence. Embrace automation with ASA and FANUC to unlock the true potential of your aftermarket automotive manufacturing processes and stay ahead in the competitive market.

To learn more about Machine Tool Tending Robots, click here.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |