FANUC’s M2000iA is the strongest 6 axis robot on the market.

FANUC M-2000iA Series Robots Ultra Heavy Payload

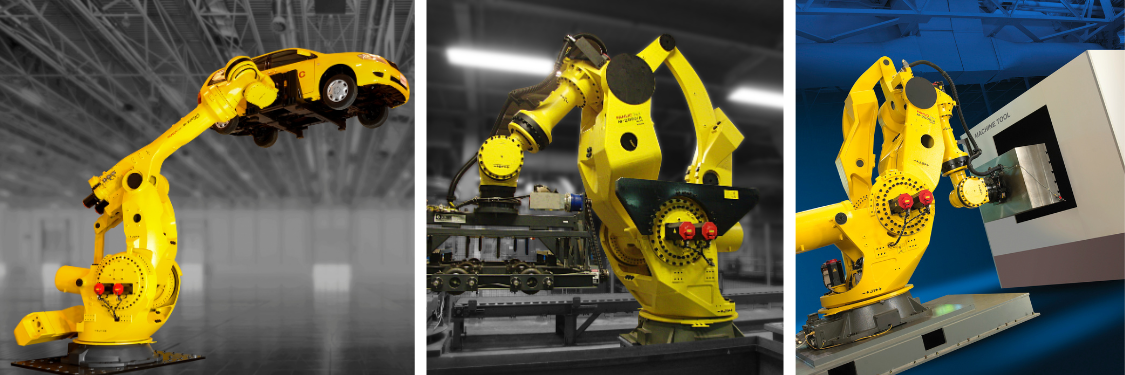

The FANUC M-2000iA Series Robots are the strongest 6 axis robot on the market, with a handling capability of up to 2.3 tonnes and a reach of up to 4.7 m. This makes it perfect for handling and palletising big components. Its vertical 6.2 m lifting stroke and horizontal reach make even the biggest workpieces simple to handle. These heavy-lifting robots are well suited for the automotive and metal industry since they can safely and effectively lift whole automobiles.

The unequalled wrist capacity of the FANUC M-2000iA Series Robots enables them to handle exceptionally large components, such as full automobile chassis and foundry parts. The FANUC M-2000iA is capable of hundreds of hours of continuous hard operation due to purpose-built, high-duty components validated by thorough testing.

FANUC M-2000IA Series Robots Reach as Far as a Crane

The FANUC M-2000iA Series Robots, which have the market’s longest reach, can do the tasks of traditional cranes, hoists, and shuttles to enhance production and reduce hazardous human labour.

The FANUC M-2000iA Series Robots are particularly suited for severe operation settings due to their wrist and shoulder-mounted motors that are protected against water and dust by an IP67 designation.

FANUC M-2000iA Series Robots have an Intelligent, Heavy Duty Construction

By smartly locating the wrist motion motors of the M-2000IA on the robot’s J3 shoulder, the possibility of damage due to heat or extreme working conditions is eliminated. Excellent air cooling at the wrist motors permits high loads and duty cycles. Moreover, despite the size of this model, tiny areas are easily accessible due to the arm’s slender form. FANUC M-2000iA Series Robots are a safe option for heavy-duty applications including dust and water since their wrist units are sealed.

How can Automated Solutions Australia Help?

ASA is your ideal FANUC robot integrator. Our engineering team at ASA are FANUC robot specialists, from concept to system designs, installations, programming and support. At Automated Solutions Australia (ASA) we thrive on helping Australian business of all sizes achieve their automation goals, enabling Australian manufacturers to compete on the world stage. For all your FANUC industrial Robot and FANUC Collaborative Robot needs, Automated Solutions Australia are your Australian industry leading experts.

Whether you are a large or small manufacturer, if you think the FANUC M-2000iA Series Robots might be the right series to automate your manufacturing process, we invite you to contact Automated Solutions Australia to explore our FANUC range today on 1800 ROBOTS.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |