One size does not fit all…by Andy Kirkham, Senior Automation Engineer ASA

The modern industrial robot has come a long way since 1961 when ‘Unimate #001’, the first industrial robot arm, appeared on the assembly line at the General Motors in Trenton, New Jersey. When entreprenuer Joseph Engelberger, the father of modern robotics, appeared on the Tonight Show with Johnny Carson in 1966 to demonstrate the Unimate, many then began to envision a future where it might be possible for artificial intelligence to completely take over industrial production processes.

Six decades later, we have not seen the Hollywood narrative of the 1956 sci-fi movie Forbidden Planet play out, where robots perform every task requested of them by their masters, and we are still some time away from full automation with a science fiction icon like ‘Robby the Robot’ taking control of manufacturing systems.

We have however seen industrial robotics improve rapidly and adapted into the most commonly recognisable form of the SCARA format (Selective Compliance Assembly Robot Arm or Selective Compliance Articulated Robot Arm). For business owners and Engineers, selecting the right SCARA robot for the task is critical for maximising ROI (Return on Investment).

There are a myriad different robot manufacturers globally, with an exhaustive number of robot models to choose from. But what makes a robot the best fit for your business? Most engineers would primarily be concerned with objective and quantitative criteria (payload, dimensions, weight, force) when making a robot selection, however the environmental and ergonomic considerations are equally as important when choosing the right robot for the application.

One of the most obvious environmental consideration factors in the ability to isolate human-robot interactions safely, with advances in collaborative robot development responding to a growing requirement for flexible alternatives to completely caging a robot – a topic we will focus on in a future article on collaborative robots.

Robot manufacturers have long identified the need for robots to endure harsh operational environments, freeing up workers from potentially hazardous conditions.

Painting robots are a good example of this, a subject we have discussed previously in the article What makes a painting robot safe?. Painting robots exemplify just one sector of a very wide area of specialist robot designs based on environmental requirements, and just as paint series robots are able to operate in a hazardous environment of a spray booth due to their specific design, there are other specially designed robots for working in the fabrication, food, and semiconductor industries and other harsh environments.

Robots designed for industrial food applications must be able to withstand regular cleaning with sanitising chemicals, and robot construction materials must conform to regulatory standards to avoid the introduction of toxins into the food processing stream. This is a good example of how the environment dictates the robot permissible for selection. Ergonomic design features would include the elimination of deep crevasses in the robot body to ensure effective cleaning and also the removal of sharp edges to prevent snagging fibres during the cleaning process.

Another example where the environmental and ergonomic considerations have driven the design of a robot, is the modern MIG or (GMAW Gas Metal Arc Welding) robot. This robot is the result of many years of research and development in the laboratories of robot manufacturers together with operating feedback from real life scenarios.

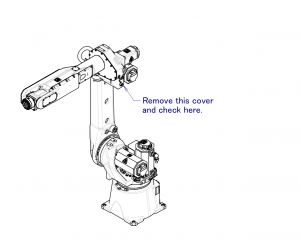

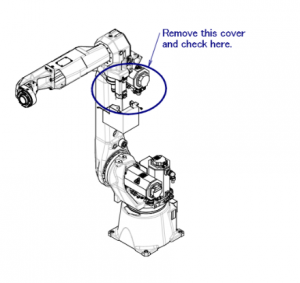

Whilst essentially identical up to the Axis Joint #3, there are some significant differences between a MIG welding robot and a standard manual handling robot (apart from the obvious end of arm tooling). Consider the M20iA and the M120iA FANUC robots. This comparison highlights how two similar robots built on the platform can customised based on their end use.

Effectively what we see between these two robots is an ergonomic variation in the wrist assembly configuration (Axis #4, #5 & #6) to allow a rear entry to the end of arm tooling, specifically for the MIG torch. Both robots offer the same payload capacity and degrees of accuracy, however the MIG customisation to the Arc Mate M120iA model has specific internal cabling for the wire feeder and welder power systems. Additionally the Arc Mate M120iA is fitted standard with Severe Dust and Liquid protection cabling for its operational environment, whereas for the M20iA these are optional additions if the manual handling application is required to operate in and environment which requires such protection.

Remember, taking a one size fits all approach generally ends up costing more in the long run. Beware of buying more robot than you need or buying into a lack of reliability. It is important to formulate a check list when selecting a robot that includes not just the payload, reach and size requirements but the environmental conditions and ergonomic criteria to select the robot for the best fit for your application

Intelligent design variations allow for robot selection to be specifically tailored to your individual needs providing a degree of certainty about selecting the right robot for your business. Please get in contact with ASA on 1800 ROBOTS to discuss your specific requirements.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |