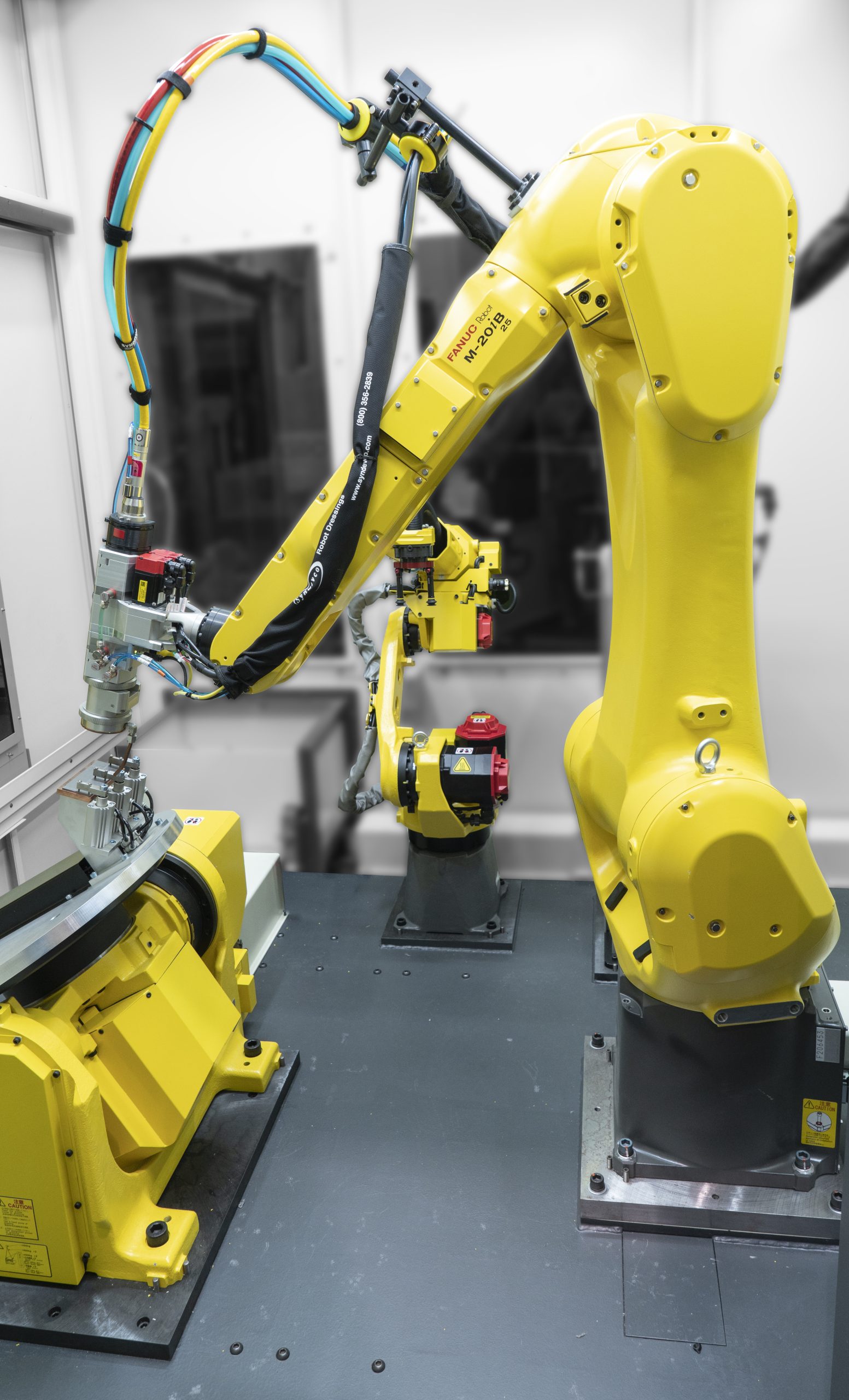

The FANUC M20 Series Robots are for Medium Payload Material Handling.

FANUC M20 Series Robots Lead the Market in Payload, Reach, and Speed

The FANUC M-20 Series Robots are the market leaders in payload, reach, and axis speed. They have a maximum reach of 2 metres and the ability to lift to 35 kilograms. In addition, the excellent design of this 6-axis machine includes the advantages of a hollow upper arm without sacrificing performance. Thus these robots are a great choice for medium-payload tasks like moving and handling materials.

FANUC M20 Series Robots Offer Enhanced Functionality

Firstly, the FANUC M-20 Series Robots’ intentional design simply enhances robot functionality. Although dress-out concerns like snagging, ripping, and rubbing are no longer an issue since all utilities are neatly contained inside the sleeve. Thus this series is deal for materials handling. So the FANUC M20 is an excellent option for medium-payload activities.

In general FANUC M20 Series Robots are well-suited for narrow cells. Due to their slim arm, wrist, and small footprint. In addition the internal cable routing essentially eliminates cable interference. Furthermore a new mounting option on the J3 arm makes it possible to put the end effector and control devices close together.

The Expert in Material Handling

Explicitly at ASA we deal in FANUC robots. While using cutting-edge servo technology, the FANUC M20 Series Robot’s quicker pick and place cycles boost throughput for weights up to 35 kg. Additionally, high wrist moments and inertia make it possible to manipulate bigger grippers and larger weights.

Since these FANUC robots have a hollow or straight wrist and cantilevered J3 arm, they have increased strength and stability. Furthermore the FANUC M-20 Series Robots have enhanced cable protection and simple maintenance.

In brief, ASA is your ideal FANUC industrial and FANUC collaborative robot integrator. Explicitly our industrial engineering team at ASA are FANUC robot specialists. Firstly from concept to system designs and lastly installations, programming and support. Undoubtedly at Automated Solutions Australia (ASA), we thrive on helping Australian businesses of all sizes achieve their automation goals. Thus enabling Australian manufacturers to compete on the world stage. So for all your FANUC M-10 Series and general industrial Robot needs and FANUC Collaborative Robot needs, Automated Solutions Australia are your Australian industry leading experts. So phone Automated Solutions today, on 1800 ROBOTS.

For the latest M-20 Series News, click here.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |