A place to keep upto date with ASA’s Automation News. From Manufacturing Monday, What We Do Wednesday, and Robot in Focus Friday. You can find the latest ASA News here!

- All

- Blog

- Case Study

- General

- Industry

- Meet Our Team

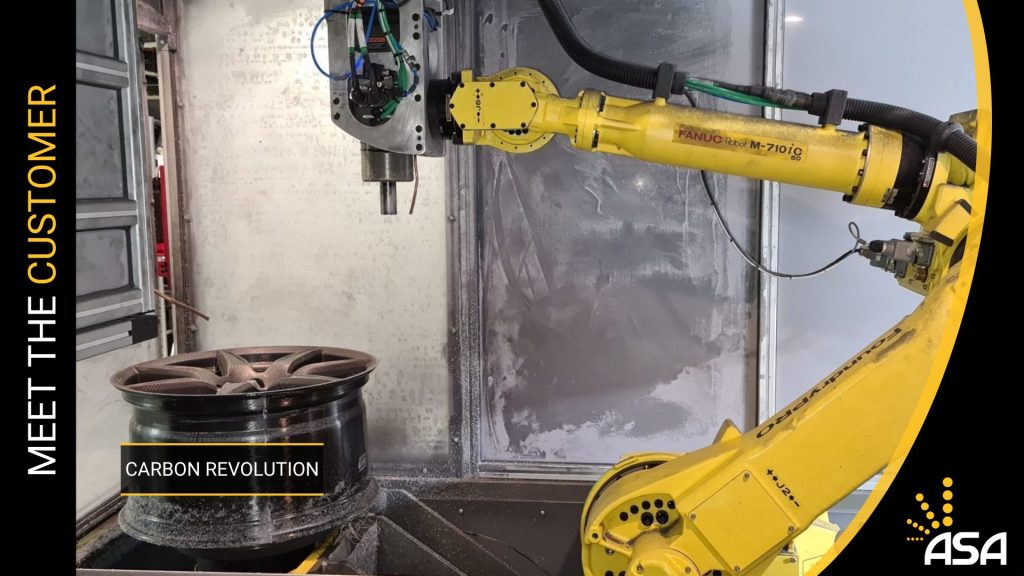

- Meet the Customer

- Uncategorised

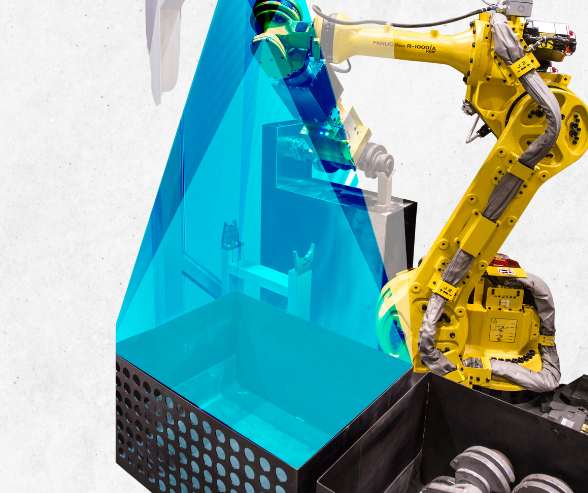

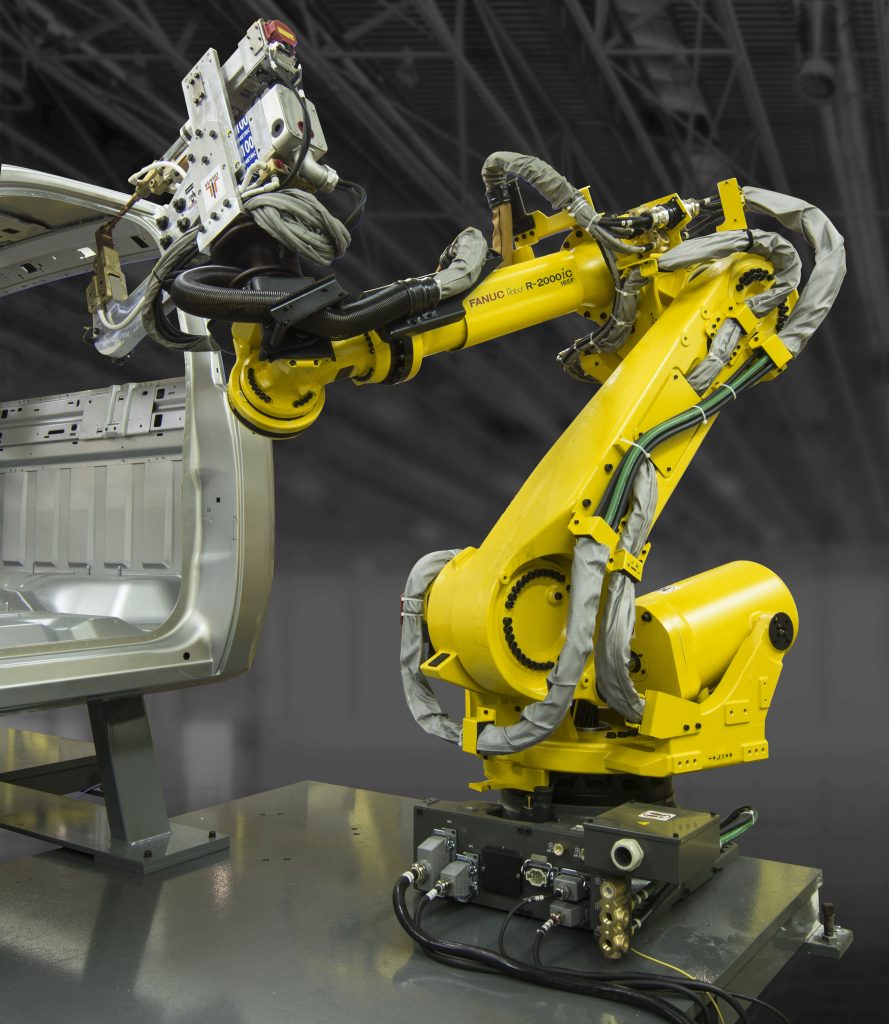

What is Industrial Automation?

What Is Industrial Automation? What is industrial automation? Ultimately, it transforms manufacturing with advanced machines and intelligent control systems. But what exactly is industrial automation, and how can it help your business thrive in a competitive market? In this guide, we’ll explain this clearly and show how Automated Solutions Australia (ASA) integrates world-leading FANUC robots …

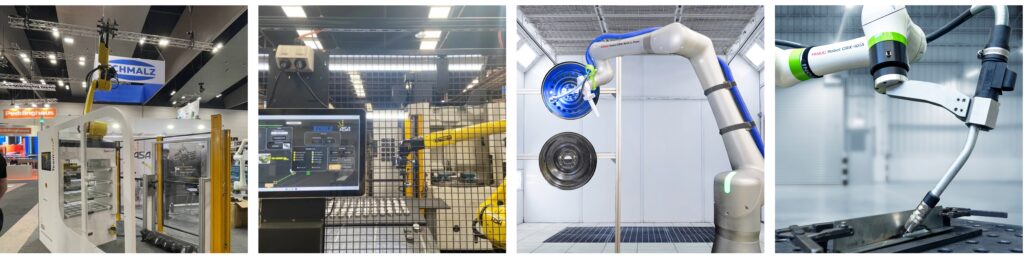

Industrial Automation Systems

Industrial Automation Systems | Harnessing Robotics Today, manufacturers actively embrace industrial automation systems powered by advanced robotics to boost efficiency, enhance precision, and improve workplace safety. By automating complex and repetitive tasks, robotics enable businesses to cut costs, elevate product quality, and accelerate production cycles. At Automated Solutions Australia (ASA), we specialise in integrating state-of-the-art …

Bespoke Automation

Bespoke Automation | Revolutionising Industries In today’s fast-paced manufacturing world, companies are actively seeking ways to improve productivity, enhance quality, and reduce costs. At ASA, our bespoke automation solutions offer the perfect solution. This approach involves tailoring automation systems to meet the specific needs of a business, optimising both technology and efficiency. As a result, …

Automated Equipment

Unlocking Efficiency with Automated Equipment | Partnering with FANUC and ASA In today’s competitive manufacturing landscape, businesses are increasingly adopting automated equipment to boost productivity, cut costs, and maintain high-quality standards. By partnering with industry leaders like FANUC and Automated Solutions Australia (ASA), you can implement automated equipment solutions tailored to your specific operational needs. …

Material Handling Equipment Australia

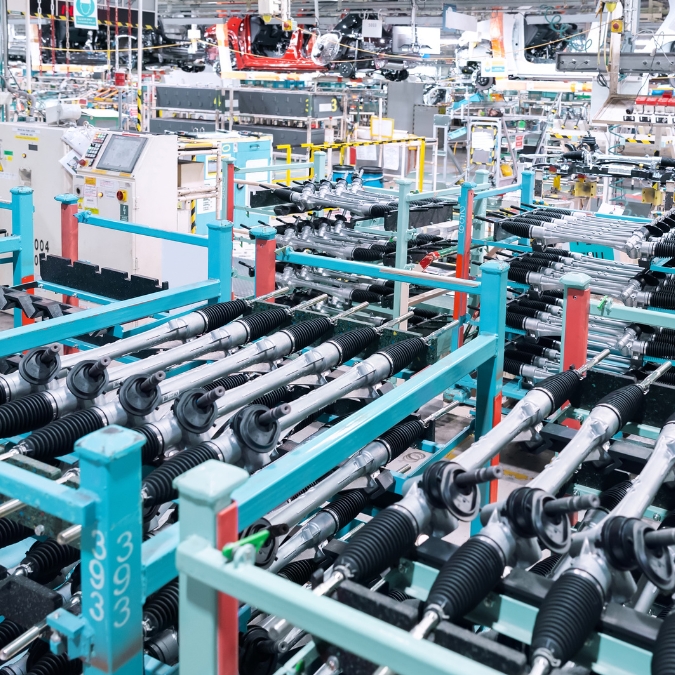

Material Handling Equipment Australia | Boost Efficiency with FANUC Robots and ASA Integration In today’s competitive industrial landscape, businesses depend heavily on efficient material handling equipment Australia to optimise manufacturing and logistics. As companies face rising labour costs, tighter deadlines, and heightened customer expectations, they increasingly deploy automation to enhance productivity, accuracy, and safety. Consequently, …

Robot Automation

Robot Automation – Revolutionising Modern Manufacturing In today’s fast-evolving industrial world, robot automation has helped in driving transformation across manufacturing. By deploying intelligent robotic systems, manufacturers achieve new levels of efficiency, precision, and flexibility. Consequently, these innovations help businesses meet growing market demands and maintain a competitive edge. This comprehensive blog explains what robotic automation …

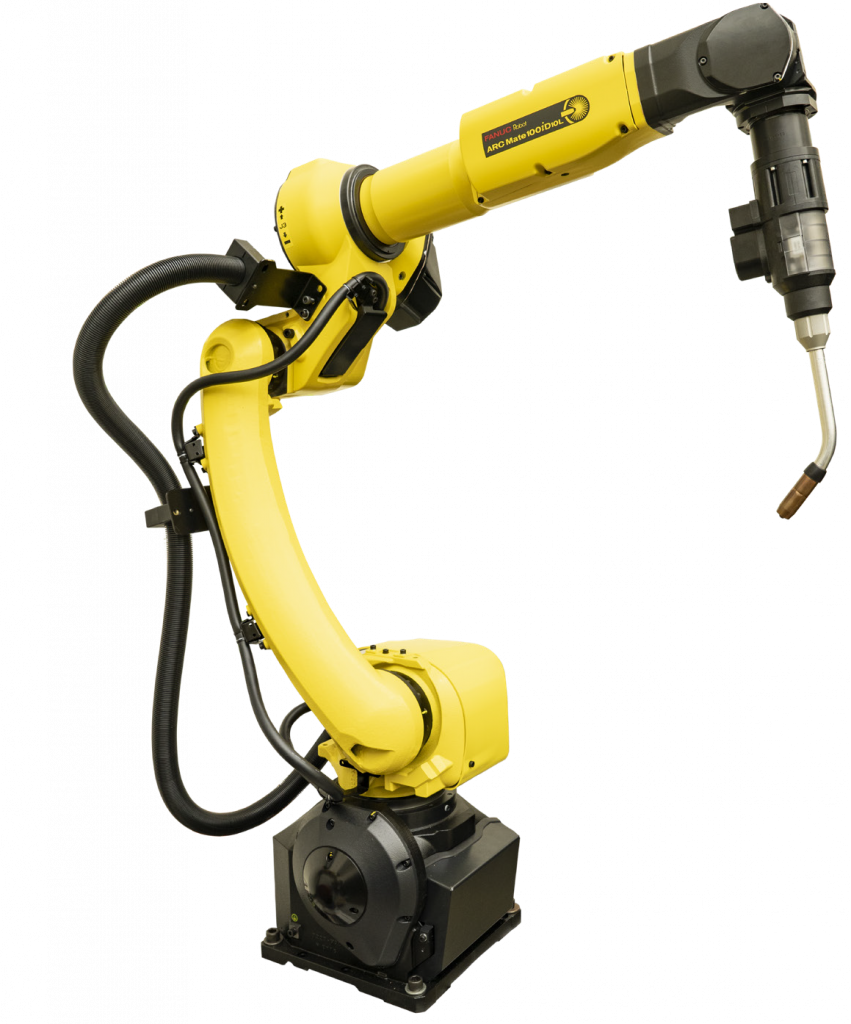

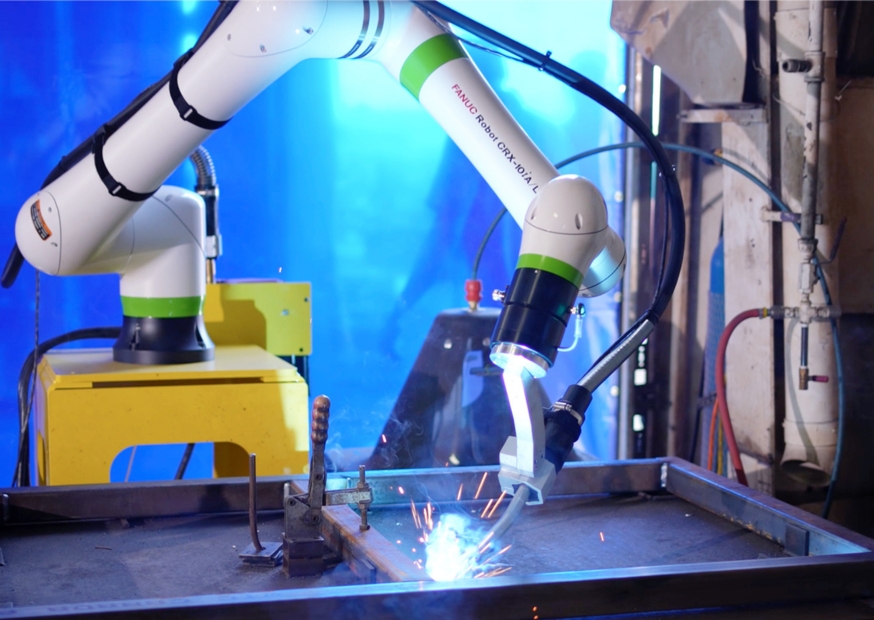

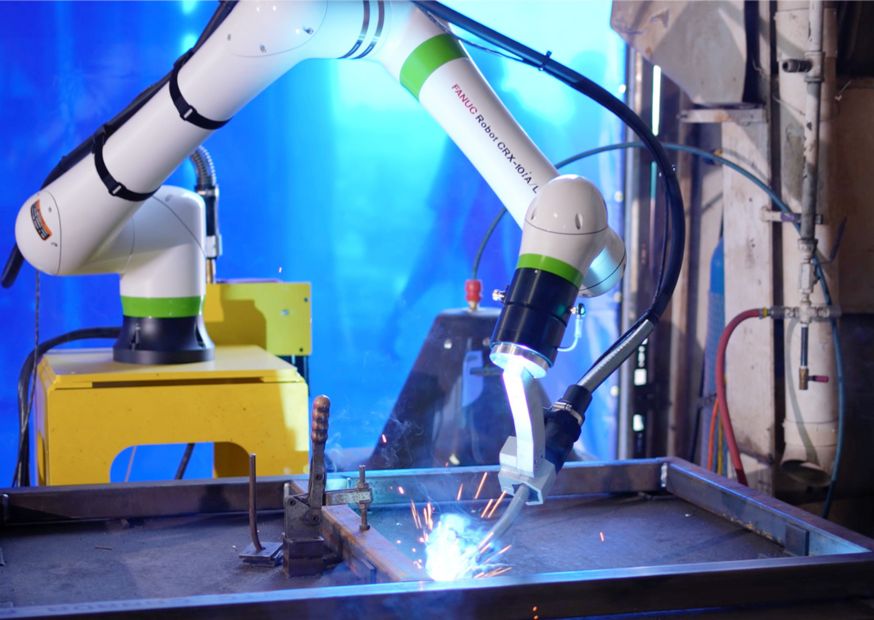

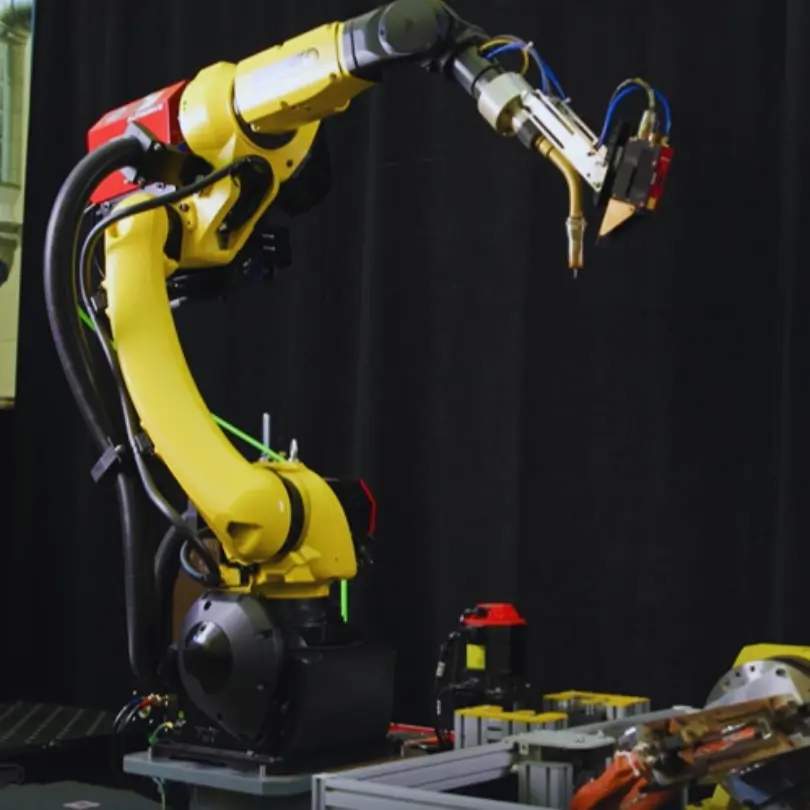

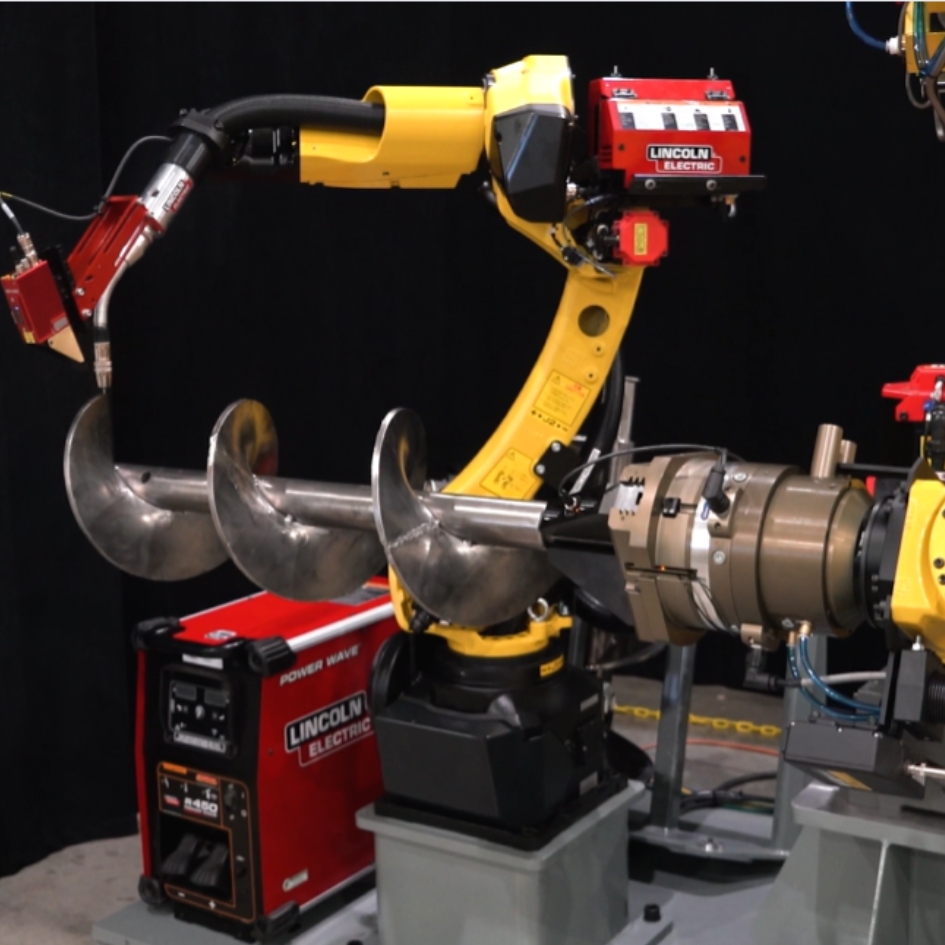

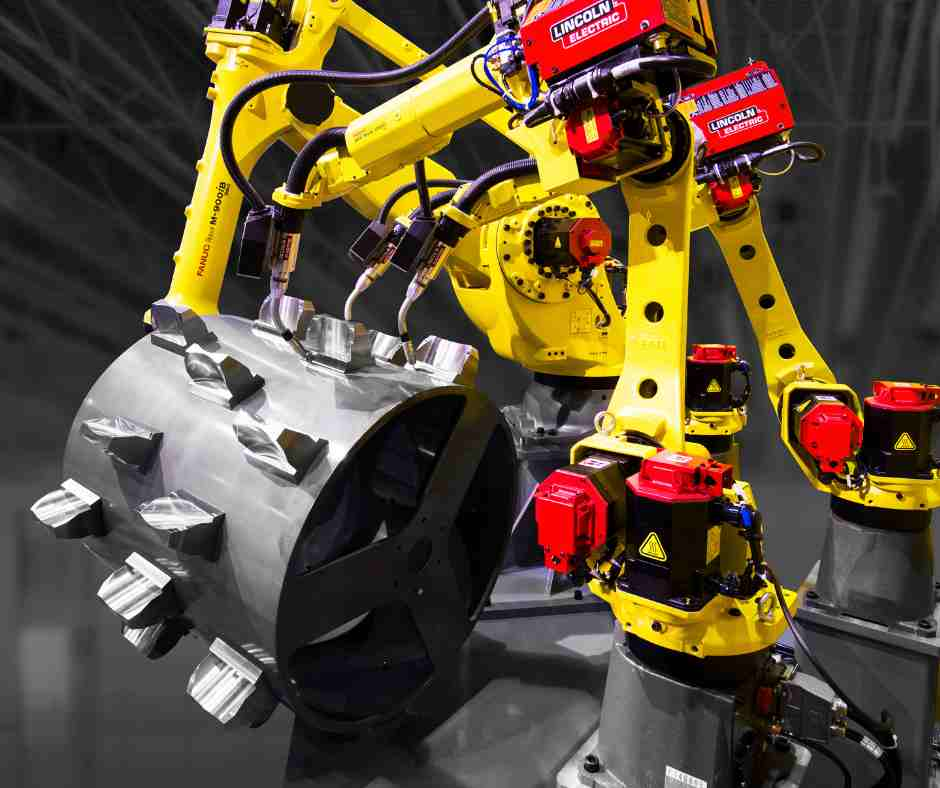

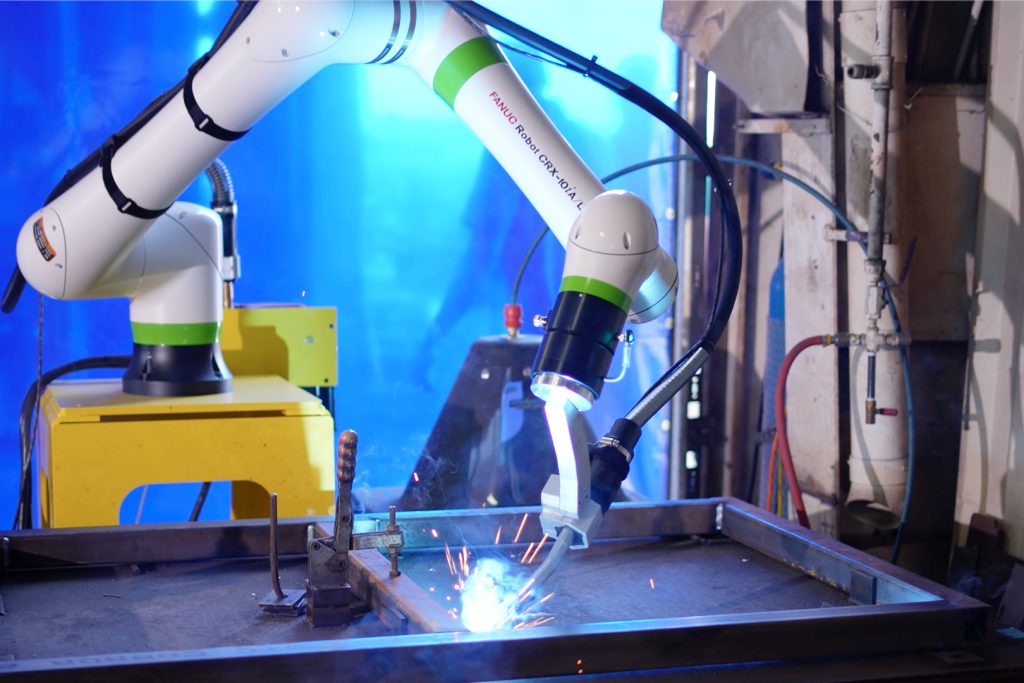

Arcmate

Arcmate | Revolutionising Welding with FANUC’s Robotics Technology Industrial automation is transforming manufacturing operations across the globe. FANUC’s Arcmate series of robotic arms stands at the forefront of industrial robotic welding. Whether you’re in automotive, aerospace, or general manufacturing, Arcmate robots optimise welding processes, delivering unmatched precision, speed, and efficiency. In this post, we will …

Engineering Automation

Unlock the Future of Manufacturing with Engineering Automation Solutions from Automated Solutions Australia (ASA) In today’s fast-paced and competitive manufacturing environment, manufacturers face constant pressure to increase efficiency, reduce costs, and maintain high precision. Engineering automation is crucial in helping businesses meet these challenges. At Automated Solutions Australia (ASA), we integrate automation technologies across various …

ASA Australia

ASA Australia – Leading the Way in Robotic Automation Solutions In today’s fast-paced manufacturing world, businesses constantly seek innovative ways to streamline processes, boost productivity, and enhance operational efficiency. At Automated Solutions Australia (ASA) we deliver cutting-edge automation solutions to businesses across Australia. With a strong focus on integrating state-of-the-art FANUC robotics into manufacturing systems, …

Automated Factories

The manufacturing industry is evolving faster than ever. As the need for increased efficiency, reduced operational costs, and superior quality intensifies, businesses turn to robotic automation for the solution. Automated factories, powered by advanced robotics and automation systems, transform production processes, enabling companies to stay competitive in an ever-demanding market. In this article, we’ll explore …

Industrial Manufacturing Equipment

Industrial Manufacturing Equipment: Optimising Production with FANUC and ASA In today’s competitive manufacturing landscape, businesses constantly seek ways to improve efficiency, reduce costs, and enhance product quality. As a result, one of the most effective strategies is investing in industrial manufacturing equipment that incorporates cutting-edge technology. At Automated Solutions Australia (ASA), we specialise in integrating …

Automated Spray Systems

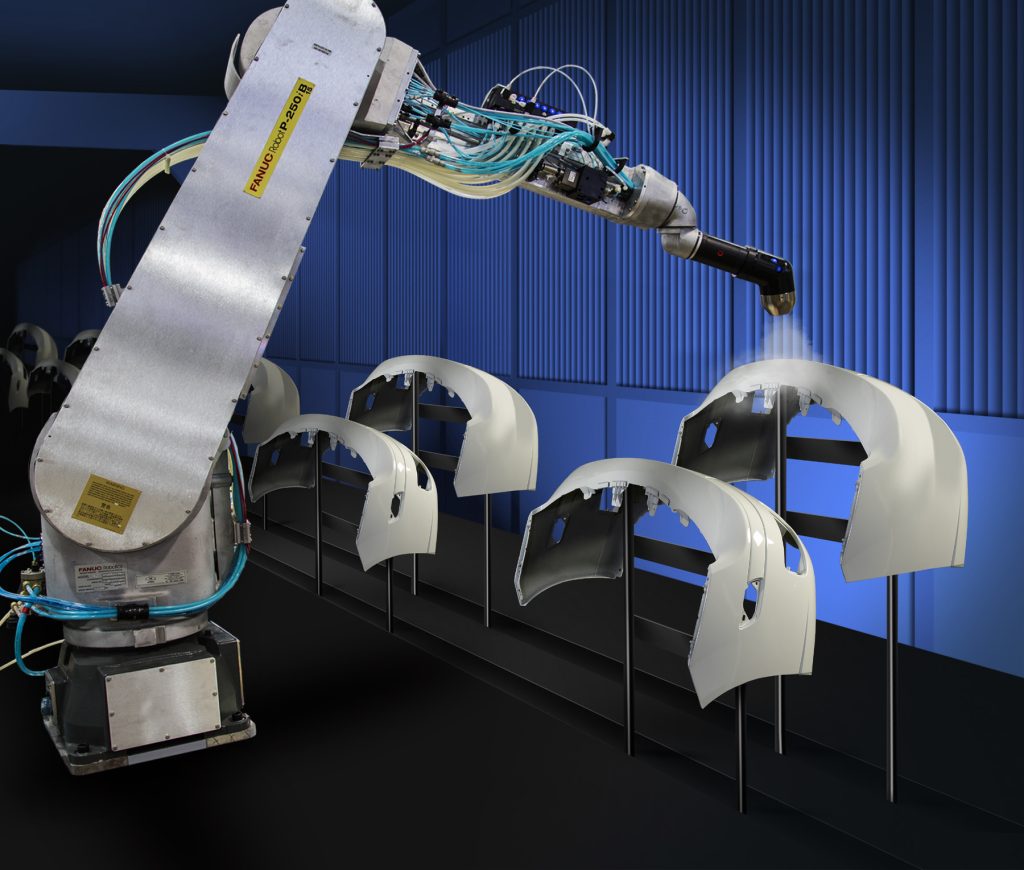

Enhance Efficiency with Automated Spray Systems and FANUC Robots In today’s competitive industrial environment, businesses automate to remain efficient and competitive. Thus, companies across various sectors actively seek ways to increase productivity, reduce costs, and improve overall product quality. One such innovation transforming industries is an automated spray system, and at Automated Solutions Australia (ASA), …

Exciting Partnership Announcement – Mitutoyo

Exciting Partnership Announcement: Automated Solutions Australia & Mitutoyo We are thrilled to announce that Automated Solutions Australia (ASA) has officially partnered with Mitutoyo Asia Pacific as a dealer for their Coordinate Measuring Machines (CMMs) in Australia. This partnership marks a significant milestone for ASA as we bring world-class precision measurement solutions to Australian industries, backed …

Automation Integrator ASA

Why Automated Solutions Australia is Your Trusted Automation Integrator for Business Efficiency In today’s competitive market, businesses must adopt new strategies to stay ahead. Automated Solutions Australia (ASA) leads the way in providing cutting-edge automation solutions. So as a trusted automation integrator, ASA helps businesses streamline operations, boost efficiency, and reduce costs with advanced automation …

Machinery Automation and Robotics

Supercharge Manufacturing with Machinery Automation and Robotics In today’s competitive manufacturing landscape, staying ahead means producing more, maintaining high quality, and doing it all while managing costs and labour shortages. That’s why more and more manufacturers are turning to machinery automation and robotics. By automating manual and repetitive tasks, you unlock a new level of …

Robot Payload

Understanding Robot Payloads | A Comprehensive Guide to FANUC’s Payload Range In industrial robotics, payload refers to the maximum weight a robot can carry or manipulate while performing its tasks. This concept is crucial because it directly impacts how robots can be applied in different industries and tasks. Therefore, understanding payload is key for engineers, …

Meet the Team – Paygen Martin

At Automated Solutions Australia (ASA), our success isn’t just driven by cutting edge robotic automation, it’s the people behind the scenes who truly drive us. One of those key team members is Paygen Martin, our Digital Marketing Specialist, who has been shaping ASA’s online presence since February 2023. From the moment she joined, Paygen hit …

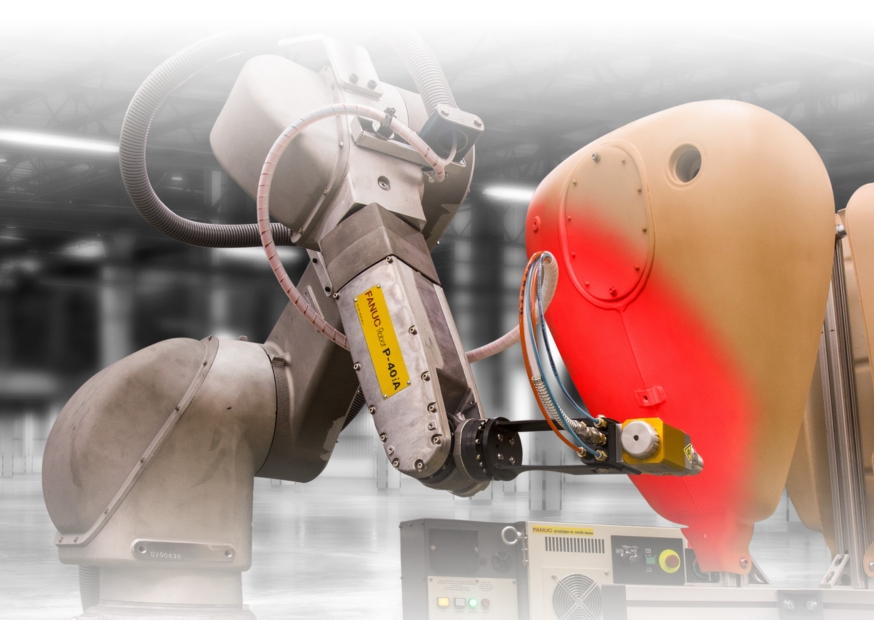

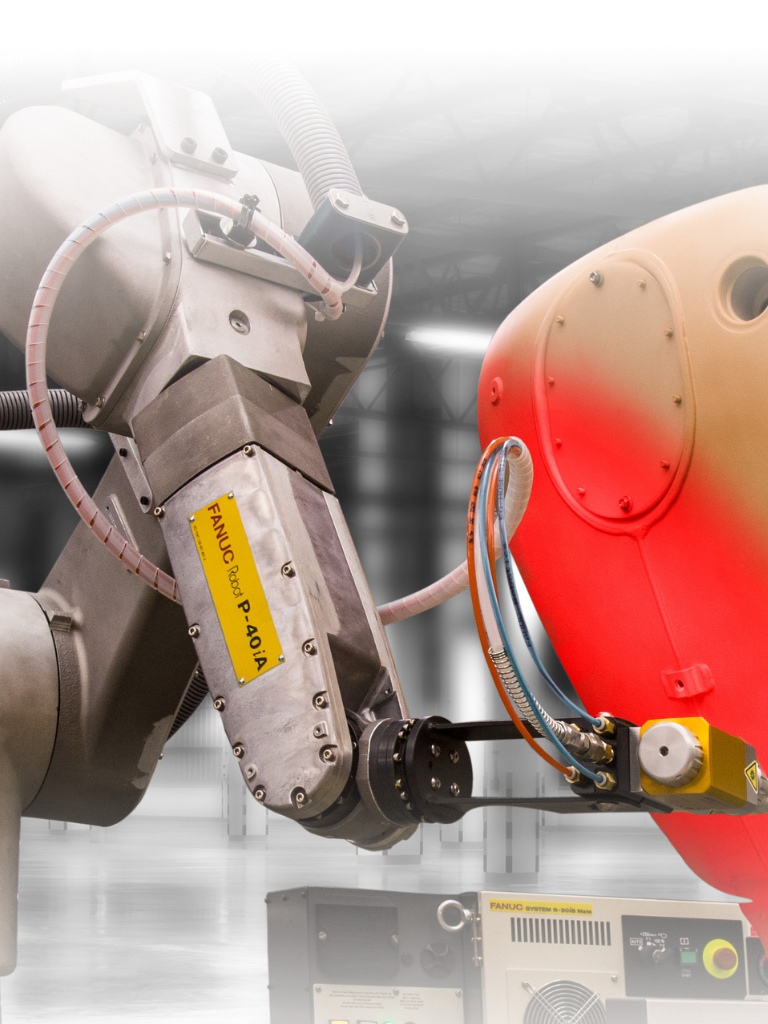

Customer in Focus: Revolutionising Paint Automation at SMR Lonsdale

SMR Lonsdale, a division of the globally recognised Motherson Group, has long been at the forefront of automotive component manufacturing. As one of the world’s fastest growing suppliers to the automotive industry, Motherson delivers high quality products to major car manufacturers worldwide, including rearview mirrors, lighting systems, decorative trims, and complex wiring solutions. Their commitment …

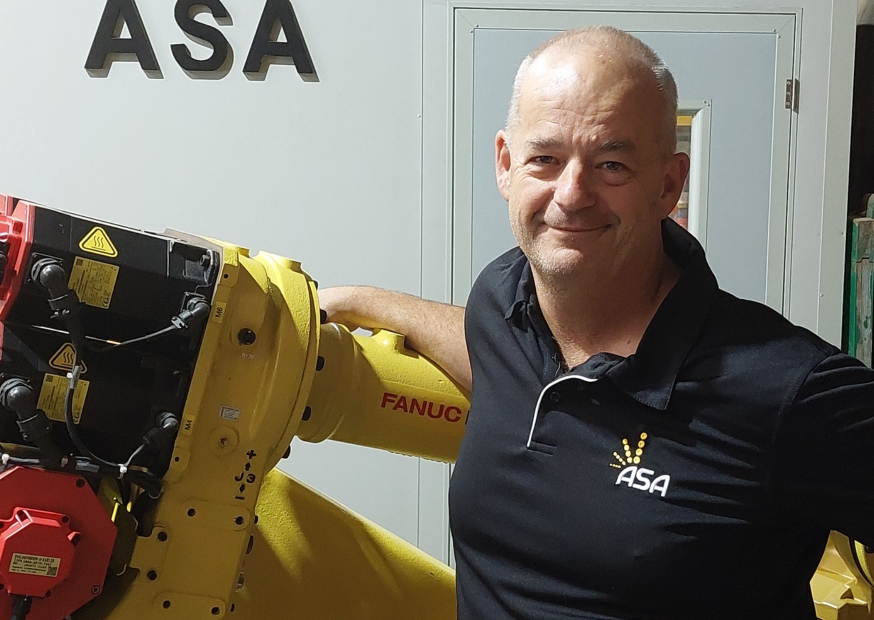

Brenton Martin 10 years

Celebrating 10 Years of Excellence: Brenton Martin at ASA We are proud to celebrate a significant milestone with Brenton Martin, Manager of the International Unit at Automated Solutions Australia (ASA), as he marks 10 years of exceptional service and leadership within the company. Brenton’s role is pivotal to the smooth operation of ASA’s day to …

Joel Esposito 10 Years

Celebrating 10 Years of Excellence: Joel Esposito at ASA We are thrilled to celebrate Joel Esposito’s remarkable 10 year journey with Automated Solutions Australia (ASA). Joel’s dedication, hard work, and commitment to excellence have made him an invaluable member of the team, and we are incredibly grateful to have him with us. Joel’s career in …

TeamMate

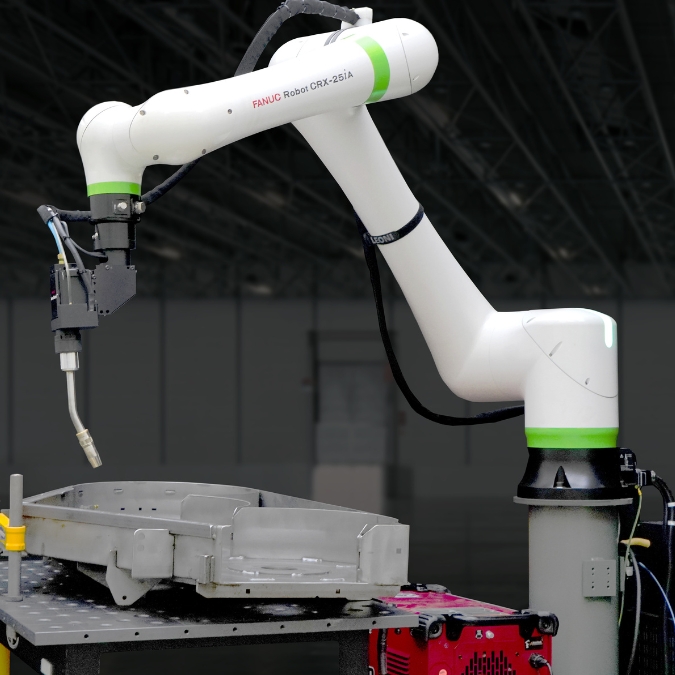

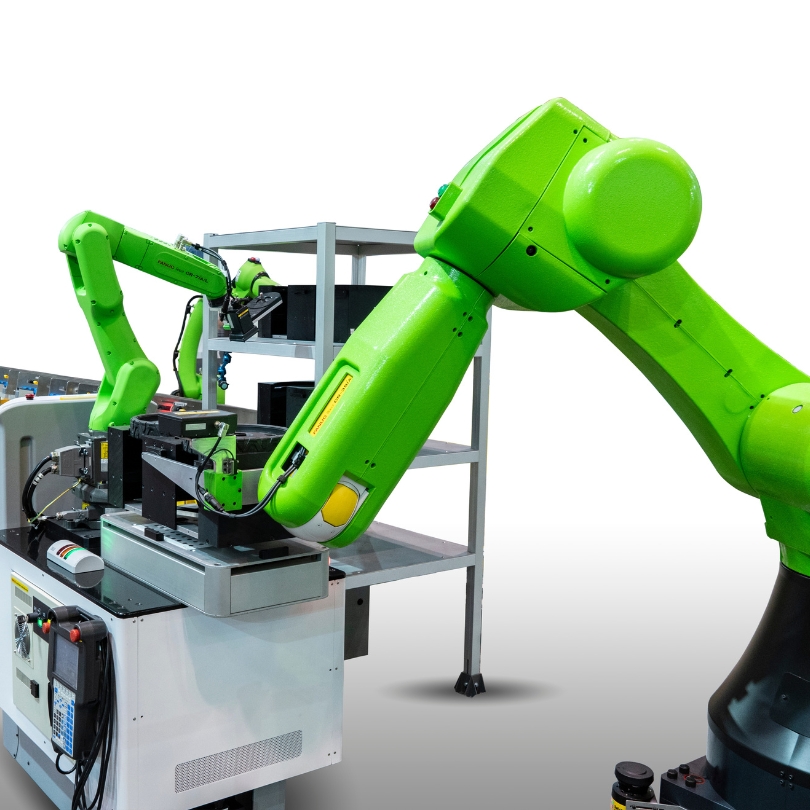

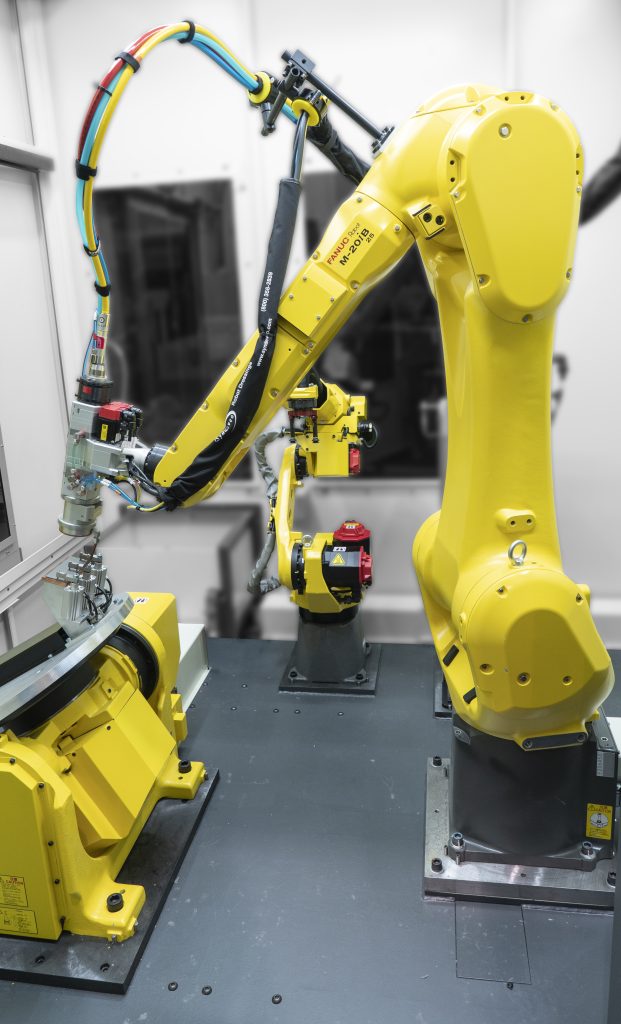

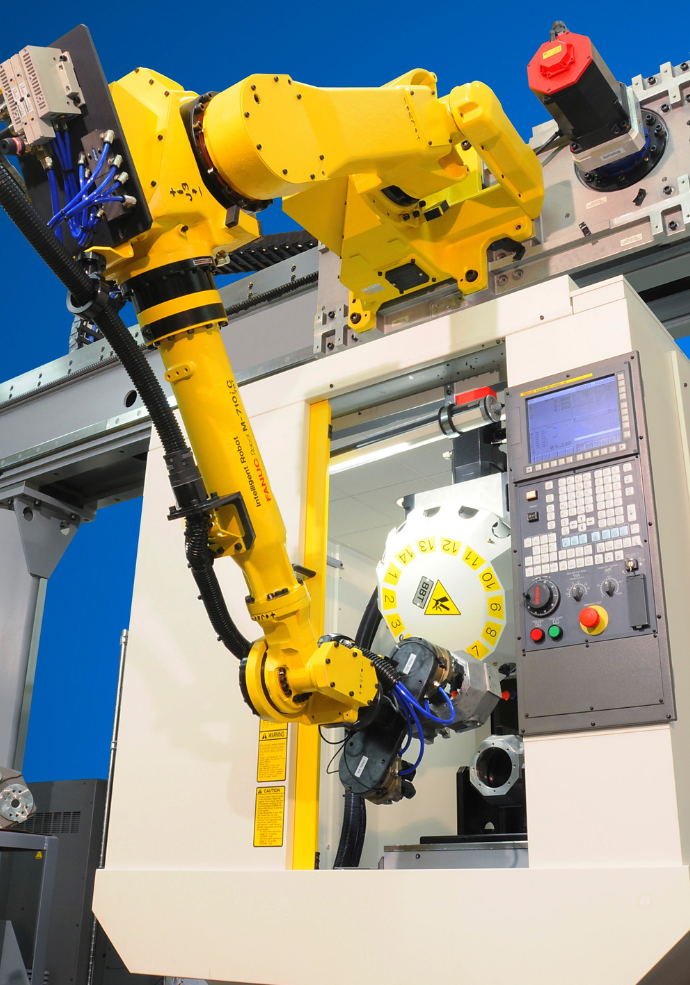

Revolutionising CNC Machine Tool Automation with TeamMate At Automated Solutions Australia, we are proud to introduce TeamMate, a state of the art robotic loading system engineered to transform the efficiency, flexibility, and productivity of CNC machine tools. Whether you’re a small, medium, or large manufacturer, TeamMate offers a seamless path to automation, helping you stay competitive …

Arc Welding Process

Arc Welding Process | Simplify Arc Welding With Robotics The arc welding process is essential in modern manufacturing, creating strong, durable joints between metal components. As industries seek higher efficiency and consistency, industrial robots have become a go-to solution. For over 20 years, Automated Solutions Australia has been integrating FANUC robots into various applications across …

Automated Warehouse Picking

Unlock the Future of Efficiency with Automated Warehouse Picking Using FANUC Robots In today’s fast-paced and highly competitive manufacturing world, businesses are always looking for ways to improve efficiency, reduce costs, and boost productivity. Automated warehouse picking has emerged as a game-changing solution to meet these goals. By integrating FANUC robots into the warehouse picking …

Engineering and Automation

Unlock the Power of Engineering and Automation to Transform Your Operations In today’s fast-paced and competitive manufacturing world, businesses constantly seek ways to improve efficiency, reduce costs, and increase productivity. Engineering and automation offer powerful solutions to achieve these goals. By integrating advanced technologies and expert engineering, you can streamline operations, reduce manual labour, and …

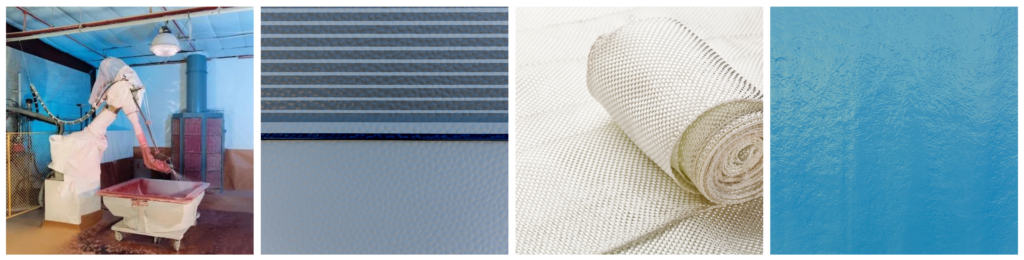

Fibreglass | Gelcoat

Unlock the Power of Fibreglass Gelcoat and Robotic Application | Fibreglass gelcoat is an essential component in the production of fibreglass-reinforced plastic (FRP) products. It acts as a protective and decorative layer, providing a smooth, durable, and glossy finish to a variety of surfaces. Fibreglass gelcoat plays a crucial role in industries such as automotive, …

Automated Palletising

Unlock the Power of Automated Palletising to Streamline Operations and Boost Efficiency In today’s fast-paced and highly competitive manufacturing world, businesses are always looking for ways to improve efficiency, reduce costs, and increase productivity. Automated palletising offers a powerful solution to achieve these goals. By integrating robotic automation into your palletising process, you can speed …

Robot Palletiser

Unlock Efficiency with a Robot Palletiser | Transform Your Manufacturing Process In today’s competitive and fast-paced manufacturing world, businesses are looking for ways to streamline operations, reduce costs, and improve efficiency. Robot palletisers provide a powerful solution to these challenges. So by integrating robotic automation into the palletising process, companies can achieve faster, more consistent …

Adhesive Dispensing System

Enhance Efficiency with an Adhesive Dispensing System Integrated by FANUC Robots from ASA In the world of modern manufacturing, precision, speed, and consistency are crucial for success. As a result, adhesive dispensing systems play a vital role in a variety of industries. From automotive to electronics, ensuring that adhesives are applied with exact accuracy is …

Custom Manufacturing

Custom Manufacturing with Bespoke Robotic Solutions In today’s competitive and rapidly evolving manufacturing landscape, businesses are continuously striving to improve efficiency, enhance product quality, and reduce costs. To address these challenges, custom manufacturing offers the ideal solution, and bespoke robotic solutions make it possible. Specifically, at Automated Solutions Australia (ASA), we specialise in providing tailored …

Automated Visual Inspection

Unlock the Power of FANUC Robots for Automated Visual Inspection In today’s fast-paced and highly competitive manufacturing landscape, businesses are continuously seeking ways to improve efficiency, ensure quality, and reduce operational costs. Automated visual inspection has emerged as one of the most powerful tools helping manufacturers achieve these goals. At Automated Solutions Australia (ASA), we …

The Advantages of Robotics

Unlocking Efficiency and Innovation: The Advantages of Industrial Robotics In today’s fast-paced and ever-evolving industrial landscape, robotics has become a game-changer, transforming the way businesses operate across various sectors. From manufacturing plants to logistics warehouses, integrating industrial robotic systems like FANUC’s solutions enables industries to increase productivity, improve safety, and drive innovation. As a result, …

Advantages of Spot Welding

The Advantages of Spot Welding | Why FANUC Robots Are the Ideal Solution When it comes to joining metal components, spot welding stands out as one of the most efficient and widely used techniques in the manufacturing industry. This process offers several key advantages that make it a preferred choice for applications across various sectors, …

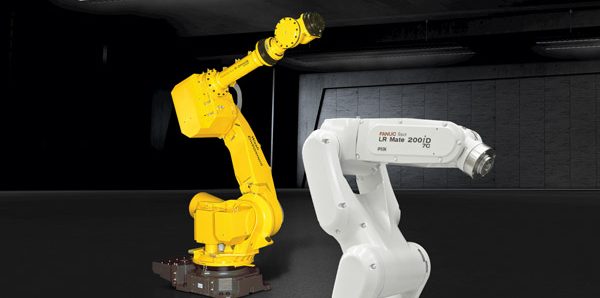

Best Industrial Robot | FANUC

Best Industrial Robot | Why FANUC Lead the Way in Automation When it comes to industrial robotics and automation, businesses worldwide constantly seek the best industrial robot, to boost productivity, improve product quality, and streamline processes. FANUC has become synonymous with top-tier industrial robots, offering innovative solutions that meet the dynamic needs of manufacturers across …

Clean Room Robots by FANUC

Ensuring Precision and Safety in Sensitive Environments In industries like pharmaceuticals, biotechnology, and electronics manufacturing, maintaining sterile and controlled environments is crucial. As a result, clean room robots play a key role in automating tasks within these sensitive settings. Thus ensuring precision and reducing the risk of contamination. Moreover, these robots are specifically designed to …

Automation Sydney

Automation Sydney | Revolutionising Industries with Cutting-Edge Solutions Automation in Sydney plays a key role in revolutionising industries. As businesses across the city embrace automation technology, they experience increased efficiency, reduced costs, and enhanced productivity. From manufacturing to logistics, automation transforms how companies operate and helps them stay competitive in a rapidly evolving market. Looking …

Industrial Sandblasting

Industrial Sandblasting | Enhancing Surface Preparation and Cleaning Industrial sandblasting is a powerful surface preparation and cleaning process. It’s used across various industries to remove rust, contaminants, paint, and other unwanted materials from metal, concrete, and other surfaces. By using high-pressure abrasive materials, sandblasting prepares surfaces for coatings, welding, or cleaning to restore the appearance …

Australian Manufacturing Industry

The Australian Manufacturing Industry | Driving Innovation and Growth The Australian manufacturing industry plays a critical role in the nation’s economy. Contributing over $100 billion to GDP and employing more than 850,000 people. In addition, this industry spans a wide range of sectors. From automotive and aerospace to food processing and electronics, supporting key export …

ARC Welding Machines

ARC Welding Machines: Revolutionising Welding Technology for Precision and Efficiency In the world of welding, precision, speed, and consistency are crucial. ARC machines have become a game-changer for industries requiring high-quality welding applications. These advanced systems use automated processes to deliver superior performance in various applications, including pipe welding, tube welding, and large-scale structural projects. …

Factory Automation

Factory Automation | Revolutionising Manufacturing with Cutting-Edge Solutions In today’s competitive manufacturing landscape, factory automation is no longer just a luxury—it’s a necessity. With advanced robotic systems, smart sensors, and cutting-edge software, factory automation is transforming how factories operate. By automating repetitive tasks, manufacturers can increase efficiency, improve quality, reduce costs, and boost overall productivity. …

Advanced Robotics in Australia

Advanced Robotics Australia | Leading the Future of Automation In today’s rapidly evolving manufacturing and automation landscape, advanced robotics are transforming industries across Australia. From automated assembly lines to cutting-edge robotic arms, Australian businesses are embracing advanced robotics. Thus boosting productivity, enhancing precision, and improving efficiency. As an industry leader in the field, Automated Solutions …

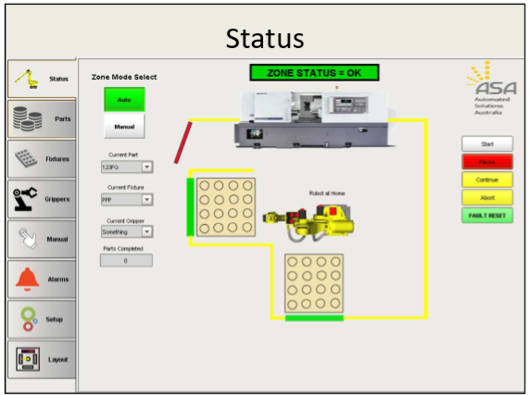

Human Machine Interface Design

Human Machine Interface Design: Revolutionising Automation with ASA’s Expertise At Automated Solutions Australia (ASA), we specialise in Human Machine Interface (HMI) design. Thus providing industry-leading solutions that simplify complex automation systems while enhancing user experience. As an experienced HMI system integrator, ASA has built a reputation over the last 20 years for delivering cutting-edge HMI …

Automation and Robotics

Transforming Industries with Automation and Robotics In today’s rapidly evolving technological landscape, automation and robotics are leading the charge in innovation, reshaping industries and boosting efficiency. As a result, businesses across sectors—from manufacturing to healthcare—are integrating automated processes and robotic technologies to stay ahead. This is not just a passing trend. Rather, it’s a transformative …

Industrial Automation Engineer

What Does an Industrial Automation Engineer Do? In today's fast-paced industrial world, industrial automation engineers use their skills to help drive efficiency, precision, and innovation. They design automated systems, improve manufacturing processes, and connect technology with production to play an essential role in modern industries. The Role of an Industrial Automation Engineer An industrial automation …

Robot Industries

Robot Industries | Automated Solutions Australia (ASA) Robot industries are reshaping how businesses operate across manufacturing, logistics, healthcare, and beyond. Robotics boosts efficiency, ensures precision, and enhances safety, making it a driving force behind modern innovation. At Automated Solutions Australia (ASA), we integrate advanced FANUC robotics to meet the unique needs of various industries. Whether …

Custom Manufacturing Solutions

Custom Manufacturing Solutions: Tailored Automation for Your Business In today’s fast-paced industrial landscape, manufacturers rely on custom manufacturing solutions to meet unique demands and stay competitive. At Automated Solutions Australia (ASA), we design, engineer, and deliver bespoke automation systems that optimise efficiency, cut costs, and improve production quality. What Are Custom Manufacturing Solutions? Custom manufacturing …

Automated Manufacturing

Automated Manufacturing | Revolutionising Efficiency and Productivity In today’s competitive landscape, automated manufacturing transforms businesses by boosting efficiency, improving quality, and helping companies stay ahead of the competition. As to meet these demands, Automated Solutions Australia (ASA) delivers state-of-the-art automation solutions tailored to your unique needs, helping you achieve operational excellence. What Exactly is Automated …

Robotic Welding Companies

Robotic Welding Companies: Why Automated Solutions Australia Leads the Way In today’s competitive manufacturing industry, choosing the right robotic welding company transforms your operations. Automated Solutions Australia (ASA) delivers tailored robotic welding solutions that enhance efficiency, precision, and safety for businesses across Australia. Why Choose ASA Among Robotic Welding Companies? With over 20 years of …

Robot Company

Why Automated Solutions Australia Is the Robot Company You Can Trust When it comes to automation, finding a reliable robot company is crucial to your success. So that’s why at Automated Solutions Australia (ASA), we combine over 20 years of expertise with cutting-edge technology to deliver robotic solutions tailored to your business needs. What Makes …

FANUC CR Series

The FANUC CR series brings the perfect balance of precision, safety, and efficiency to your workplace. Designed with adaptability in mind, these collaborative robots (cobots) integrate seamlessly into various industrial processes, making automation accessible for businesses of all sizes. What Is the FANUC CR Series? The FANUC CR range includes versatile collaborative robots with a …

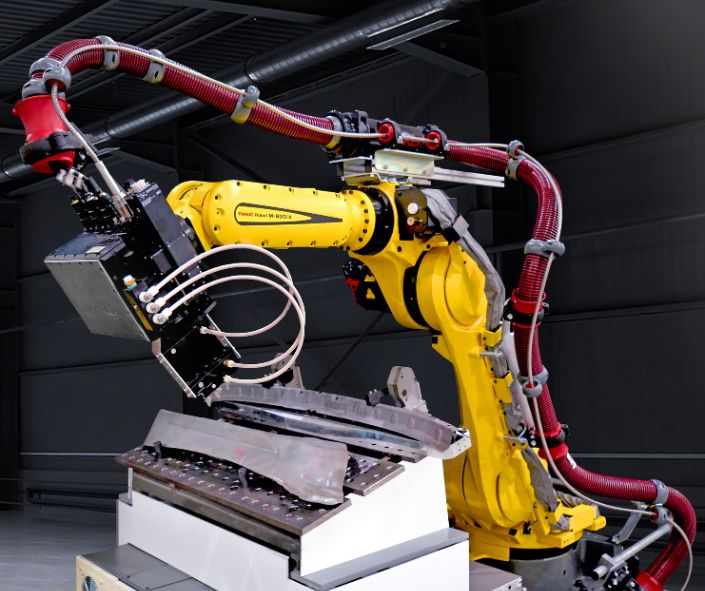

Machine Tending Robot

Transform Your Operations with a Machine Tending Robot A machine tending robot provides a reliable and efficient solution to handle repetitive and labour-intensive tasks, allowing businesses to focus on innovation and growth. At Automated Solutions Australia (ASA), we specialise in integrating advanced robotic systems, including FANUC’s world-class machine tending robots, to help Australian businesses thrive …

Industrial Automation Projects

Industrial Automation Projects | Automated Solutions Australia Are you ready to streamline your operations and boost productivity? In today’s fast-paced market, industrial automation projects modernise manufacturing processes and keep your business competitive. Automated Solutions Australia (ASA) designs and deliver bespoke automation solutions that drive efficiency and innovation. What Are Industrial Automation Projects? Industrial automation projects …

Robotics Definition

Robotics Definition | A Comprehensive Overview of Modern Technology In today's fast-paced world, robotics revolutionises industries across the globe. But what does robotics definition really mean? Simply put, robotics focuses on designing, building, and operating robots. These machines carry out tasks autonomously or semi-autonomously, enhancing efficiency, precision, and safety in various sectors. What is Robotics? …

Robotics and Manufacturing

Robotics and Manufacturing | Efficiency and Precision In today’s fast-paced and competitive industrial landscape, businesses constantly seek ways to improve efficiency, reduce downtime, and boost production quality. As a result, robotics and manufacturing are becoming inseparable, driving industry advancements and ensuring companies remain competitive. The integration of robotic technology into manufacturing processes is no longer …

Automatic Blasting Machine

Automatic Blasting Machine Powered by FANUC Robots In today’s fast-paced manufacturing environment, efficiency and precision are more critical than ever. An automatic blasting machine has become a game-changer for industries like automotive, aerospace, and manufacturing. By integrating FANUC robots into your blasting process, you can achieve faster, more consistent results while reducing human error. Achieve …

Industrial Welding Robots

Industrial Welding Robots by FANUC - Precision, Speed, and Efficiency with ASA In today’s fast-paced manufacturing world robots are transforming the welding process by offering unmatched precision, speed, and efficiency. So as businesses face increasing demands for high-quality products and faster production times, they turn to FANUC industrial welding robots to streamline operations. FANUC, a …

Industrial Robotics Companies

Industrial Robotics Companies | FANUC and ASA Leading the Way In today’s fast-paced manufacturing world, industrial robotics companies drive transformation by boosting efficiency, improving productivity, and enhancing safety. Such companies provide cutting-edge robotics solutions that help businesses reduce costs, enhance output quality, and streamline operations. Among these leaders, FANUC stand out for their innovative technology …

Cobots and Robots

Cobots vs. Robots The industrial automation landscape is evolving rapidly, and cobots (collaborative robots) and robots are at the forefront of this transformation. These advanced machines are revolutionising workflows, boosting efficiency, and enhancing safety across industries. In this blog, we will explore the key differences between cobots and industrial robots, how they are reshaping industries, …

Connecting with Future Innovators: Melissa Boonzaayer and the VEX Robotics State Championships

At Automated Solutions Australia (ASA), we’re passionate about fostering STEM education and empowering the next generation of innovators. That’s why we’re thrilled to celebrate the incredible contributions of our team member, Melissa Boonzaayer, who has been making a difference by judging VEX Robotics competitions, including the recent State Championships at UniSA in South Australia. VEX …

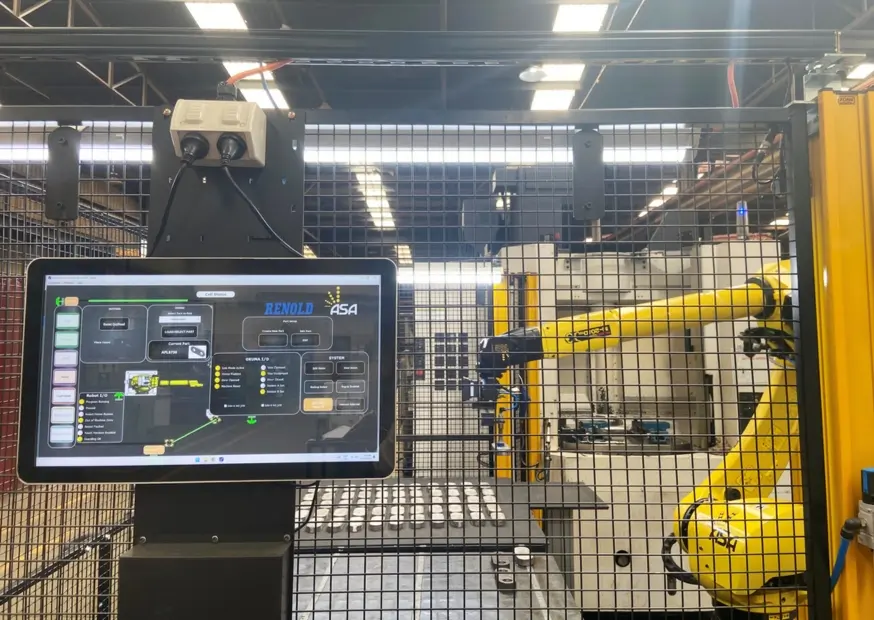

Meet the Customer – Renold Australia

Automated Solutions Australia (ASA) is proud to have partnered with Renold Australia, an industry leader with a long history of innovation, to develop and implement an advanced robotic machine tending solution at Renold’s Melbourne facility. This partnership showcases ASA’s automation expertise alongside Renold’s ongoing commitment to adopting cutting edge technologies to drive manufacturing excellence. One …

Meet The Team – Curtis Forde

"When I first joined ASA, I was amazed by how much everyone genuinely loved what they were doing," says Curtis Forde, a graduate mechatronics engineer at Automated Solutions Australia. Curtis, who completed his studies at Swinburne University, discovered his passion for electrical systems design and software programming during his academic journey. At ASA, his role …

Shot Blasting Services

Shot Blasting Services: Transforming Surface Preparation Across Industries Shot blasting services revolutionise surface preparation by delivering precision, efficiency, and reliability. This process propels abrasive materials, like steel shots or grit, at high speeds to clean, polish, or strengthen surfaces. With shot blasting, you can quickly remove rust, paint, and other contaminants while preparing surfaces for …

Adelaide Automation

Adelaide Automation | Automated Solutions Australia Drive Innovation and Growth in South Australia Businesses across Adelaide are turning to automation to streamline operations, cut costs, and boost productivity. For example, from assembly lines, machine tending, paint finishing, to material handling and packaging, automation is enhancing a wide array of applications. Furthermore, by adopting cutting-edge technologies …

Robot Solution

Robot Solution: Revolutionising Industries with Automation In today’s fast-paced world, businesses are turning to automation to stay competitive, and a robot solution is often the key to achieving greater efficiency, precision, and scalability. Robots operate in a number of industries, particularly automotive and manufacturing. Additionally, they have become indispensable tools in industries like healthcare, defence …

Collaborative Welding Robots

Collaborative Welding Robot: Revolutionising the Future of Industy In recent years, the collaborative welding robot has helped to transform industrial automation by combining precision, efficiency, and safety in welding processes. These cobots, designed to work side-by-side with human operators, handle complex and repetitive welding tasks seamlessly. Unlike traditional robots that require separation from workers, collaborative …

Robots in Business

Robots in Business: Transforming Productivity and Efficiency Across Industries In today’s fast-paced world, robots in business drive productivity, accuracy, and efficiency across sectors. These advanced robots handle tasks ranging from routine assembly to complex quality control, streamlining operations wherever they’re applied. More than ever, businesses rely on robotics to automate time-consuming tasks, allowing human teams …

Robotic Spot Welding

Robotic Spot Welding: Precision and Efficiency in Modern Manufacturing Robotic spot welding has transformed the manufacturing industry. Delivering high levels of precision, speed, and consistency in welding applications. This automation process involves using robots to perform spot welds. These are typically short, concentrated welds applied at specific points to join metal surfaces together. The accuracy …

Palletisers

Palletisers | Revolutionising Material Handling in Modern Industries In today’s fast-paced industrial landscape, palletisers are essential for efficient material handling. These machines simplify the process of stacking products onto pallets, improving speed, accuracy, and consistency in production lines. As businesses strive to meet higher demands, palletisers play a crucial role in keeping operations streamlined and …

Cobot

The Cobot | Transforming the Future of Collaborative Robotics in Industry The term cobot, or collaborative robot, refers to robots specifically designed to work safely alongside humans in various industries. The concept of cobots first emerged in the 1990s. It was born out of a need for robots that could perform repetitive or complex tasks …

Robots Used in Industry

Robots Used in Industry | Enhancing Efficiency and Precision Across Sectors In today’s fast-paced world, robots used in industry are indispensable tools for businesses aiming to improve efficiency, quality, and productivity. These advanced machines are now an integral part of manufacturing, assembly, and logistics operations worldwide. By automating repetitive tasks, robots not only reduce human …

Automated Material Handling Systems

Automated Material Handling System | Transforming Efficiency and Productivity In today’s fast-paced manufacturing environment, an automated material handling system is essential for businesses looking to streamline operations. Additionally they see businesses improve accuracy, and reduce labour costs. These systems handle the movement, storage, and control of materials automatically, enabling a smoother and more efficient production …

PLC Industrial Automation

PLC Industrial Automation: Transforming Efficiency and Precision with Advanced Solutions In the ever-evolving landscape of industrial automation, PLC industrial automation is a vital force, driving efficiency, reliability, and precision across production lines. Programmable Logic Controllers (PLCs) are at the heart of these advancements, acting as powerful industrial computers that manage and control automated systems seamlessly. …

Robotic Solutions

Robotic Solutions: Powering the Future of Automation with FANUC Robots In today’s fast-evolving industrial landscape, robotic solutions are transforming the way businesses operate. From streamlining production lines to ensuring precise quality control, robots have become essential tools for companies seeking efficiency, consistency, and speed. At Automated Solutions Australia, we specialise in providing high-quality robotic solutions. …

Automated Robot

The Future of Manufacturing | Embracing Automated Robots with FANUC Robotics In today’s fast-paced industrial landscape, automated robots are revolutionising how companies approach production, quality control, and efficiency. These robots, designed to perform tasks autonomously, not only streamline manufacturing but also improve precision, consistency, and safety. Therefore, automated robots, like those offered by FANUC, have …

Automatic Solutions

Unlocking Efficiency with Automatic Solutions With Robotics In today's fast-paced manufacturing environment, automatic solutions are essential for enhancing productivity and maintaining competitive advantages. Businesses are increasingly turning to automation to streamline operations, reduce costs, and improve overall quality. By implementing advanced robotic technologies, companies can optimise their workflows and minimise human error, leading to higher …

Collaborative Robots in Manufacturing

The Rise of Collaborative Robots in Manufacturing In recent years, collaborative robots have gained significant traction in the manufacturing sector, revolutionising how companies approach automation. Unlike traditional industrial robots, which often operate in isolation, collaborative robots (or cobots) are designed to work alongside human workers safely and efficiently. This innovative approach enables manufacturers to streamline …

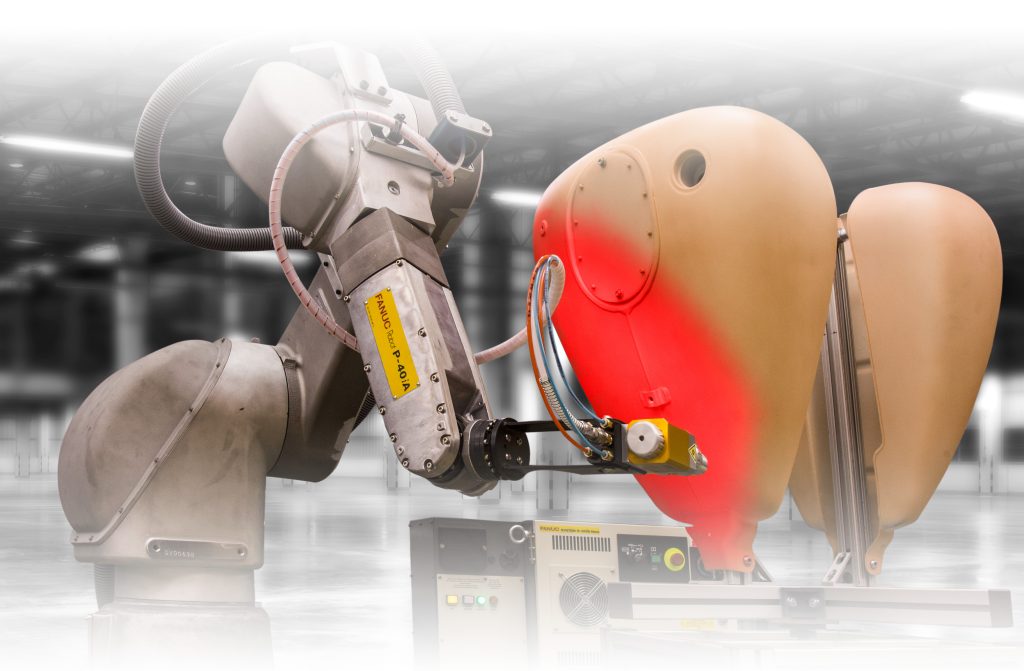

Automatic Coating

Elevate Your Production with Automatic Coating Solutions In today’s fast-paced manufacturing environment, automatic coating has emerged as a vital process for ensuring high-quality finishes and increased efficiency. By integrating FANUC robots, companies can streamline their coating applications, delivering precise and consistent results every time. The Benefits of Automatic Coating First and foremost, automatic coating systems …

Australia Wide Automation

Your Trusted Partner in Automation Solutions Across Australia - ASA At Automated Solutions Australia, we pride ourselves on being a leading provider of automation solutions tailored to meet the unique needs of various industries. Whether you're searching for automation companies in Melbourne, automation companies Adelaide, automation companies in Perth, automation companies in Sydney, automation companies …

CNC Machinery Solutions

Unlock Efficiency with CNC Machinery Solutions In the world of manufacturing, CNC machinery solutions are crucial for enhancing productivity and precision. As industries evolve, companies are increasingly looking for ways to automate their existing CNC (Computer Numerical Control) systems to improve efficiency and reduce costs. Automating your CNC machinery not only streamlines operations but also …

Automatic Material Handling

Streamline Your Operations with Automatic Material Handling In today's fast-paced industrial environment, automatic material handling is essential for improving efficiency and productivity. By automating the movement, protection, storage, and control of materials, businesses can minimise manual labor and reduce operational costs. This innovative approach not only accelerates workflows but also enhances accuracy and safety across …

Auto Robots

Discover the Benefits of Auto Robots in Modern Manufacturing In the realm of modern manufacturing, auto robots (automotive robots) are transforming the way businesses operate. These advanced machines enhance efficiency, reduce costs, and improve product quality across various industries. As companies increasingly adopt automation, the demand for reliable and versatile auto robots continues to rise. …

Automated Manufacturing Systems

Enhance Your Operations with Automated Manufacturing Systems In today’s competitive landscape, automated manufacturing systems are essential for improving productivity and efficiency. These systems utilise advanced technologies to streamline production processes, minimise human error, and enhance product quality. As businesses increasingly embrace automation, the demand for innovative solutions continues to grow. Moreover, companies that implement automated …

Automatic Systems

Unlock Efficiency with Automatic Systems & Robotic Automation In today’s fast-paced industrial landscape, automatic systems are transforming the way businesses operate. By leveraging automation, companies can enhance efficiency, reduce costs, and improve product quality. Automatic systems streamline processes and minimise manual intervention, allowing businesses to focus on growth and innovation. The Power of Automatic Systems …

Welding Robotics

Efficiency, Precision and Increased Throughput with Welding Robotics In the ever-evolving landscape of manufacturing, welding robotics is becoming indispensable for enhancing productivity and quality. Such advanced systems automate the welding process, allowing manufacturers to achieve precision and consistency, that manual methods simply cannot match. By integrating welding robots into production lines, businesses can significantly reduce …

Arc Welding Robots

Discover the Power of Arc Welding Robots In the world of industrial manufacturing, arc welding robots are transforming the way we approach welding tasks. These advanced machines provide unmatched precision and efficiency, allowing businesses to achieve superior quality in their welded products. By automating the welding process, manufacturers can enhance productivity while reducing the risk …

Top Robot Manufacturers

Discover the Top Robot Manufacturers: Why FANUC Leads the Pack In today’s rapidly evolving industrial landscape, automation plays a crucial role in enhancing efficiency and productivity. When it comes to top robot manufacturers, FANUC stands out as a leader in the field. Consistently pushing the boundaries of innovation and performance. Reliability Among the Top Robot …

Dispensing Robot

Elevate Your Manufacturing with a Dispensing Robot In the fast-paced world of modern manufacturing, achieving precision and efficiency is crucial. One of the most effective ways to attain both is through the implementation of a dispensing robot. This innovative technology allows for the accurate application of materials such as adhesives, sealants, and other fluids, ensuring …

Automated Spray Booth

Enhance Your Operations with a Robotically Automated Spray Booth | Integrate with ASA Are you ready to transform your painting processes? Automated spray booths are the perfect solution for enhancing efficiency, quality, and consistency in your operations. At Automated Solutions Australia (ASA), we specialise in integrating FANUC paint series robots into automated spray booths, ensuring …

Manufacturing Automation

Discover the Future of Manufacturing Automation Are you ready to elevate your production processes? Manufacturing automation is transforming industries worldwide, enabling businesses to achieve unparalleled efficiency and quality. At Automated Solutions Australia (ASA), we understand the challenges you face, and we’re here to help you navigate the transition to automation with ease. Embrace Manufacturing Automation …

Welding Robot

Unlock Efficiency with a Welding Robot Are you ready to transform your manufacturing process? Welding robot technology is at the forefront of industrial automation, offering precision, speed, and efficiency like never before. At Automated Solutions Australia, we specialise in integrating FANUC robots for a number of applications. This including welding, ensuring you stay highly competitive …

Industrial Robotics Industry

Exploring the Industrial Robotics Industry The industrial robotics industry is rapidly changing the way businesses operate across various sectors. From manufacturing to automotive, these cutting-edge technologies are revolutionising processes, helping companies become more efficient, productive, and cost-effective. In an era where automation is key to staying competitive, industrial robotics are becoming a vital part of …

Automation Robots

What Are Automation Robots? Automation robots are transforming industries by taking over repetitive tasks that once required manual labour. These robots are designed to handle a wide range of functions. Such as; assembly, packaging, paint finishing welding and inspection. By incorporating automation robots into your processes, you can achieve higher efficiency, reduce errors, and significantly …

What is Spot Welding?

What is Spot Welding? Spot welding is a welding technique that joins two or more metal sheets together. Pressure and heat are applied to specific points. This method works by using an electrical current to create heat between two metal surfaces. Thus melting them enough to fuse together. It's common in industries such as automotive …

Industrial Automation Industry

Industrial Automation Industry | The Future of Efficiency Industrial automation industries are completely transforming how businesses operate across various sectors. So from manufacturing and automotive to food processing and electronics, automation helps companies boost efficiency, reduce costs, and maintain consistent quality. In today’s fast-paced world, industries are turning to automation to stay competitive. In turn, …

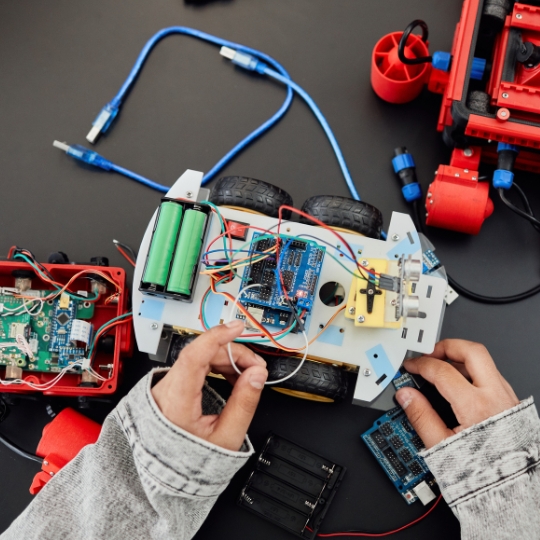

Inspiring the Next Generation: A Week with Lily at Automated Solutions Australia

Recently, Automated Solutions Australia had the pleasure of hosting Lily, a Year 10 student, for her work experience placement. This opportunity provided Lily with hands on learning and an exploration into the world of robotics and engineering. Throughout her week, Lily worked under the direct supervision of ASA’s Melbourne engineering teams on a variety of …

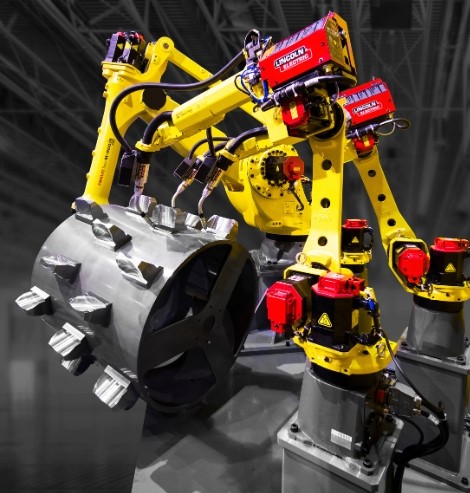

Customer in Focus | Quick Ally

In a recent project that highlights the synergy between technology and industry, Automated Solutions Australia (ASA) collaborated with QuickAlly Access Solutions to upgrade their welding capabilities at their Brisbane facility. This project is a perfect example of how innovative automation solutions can enhance manufacturing processes, particularly for a company as committed to quality and safety …

Meet the Team | Alex Jackson

At just 22 years old, Alex Jackson is already making significant strides in the world of robotic automation. As a Mechatronics graduate working full time at Automated Solutions Australia (ASA) in Melbourne, Alex is part of a team that designs, assembles, installs, and commissions robotic solutions across Australia and New Zealand. His journey is one …

Fibreglass Coating | Gelcoat Fibreglass

Understanding Fibreglass Coating and Fibreglass Gel Coat | What You Need to Know When it comes to creating durable and attractive surfaces, fibreglass coating and fibreglass gel coat play crucial roles. Various industries, from automotive to marine, widely use these materials.This is because they provide a strong, protective finish. Thus enhancing both the appearance and …

Robotic Welders for Sale

Welding Robots - Robotic Welders for Sale: Transform Your Welding Process Are you in the market for welding robots? If so, you’re likely looking to enhance your production capabilities with the latest in welding automation technology. Whether you focus on MIG, TIG, or spot welding, the right robotic solution can make all the difference in …

Automation Robotics

Understanding Automation Robotics | Automation Robotics for Enhancing Industries Automation robotics uses robotic systems to automate tasks that humans traditionally perform. These systems are designed to handle repetitive, complex, or hazardous tasks with greater precision, speed, and efficiency. In industries ranging from manufacturing and automotive to electronics and healthcare, automation robotics is playing a vital …

Robot Suppliers

Choosing the Right Robot Suppliers: Why It Matters In today's fast-paced industrial landscape, selecting the right robot suppliers is a crucial decision for the success of your automation projects. The right supplier can provide you with the perfect robotic solutions that not only meet your current needs but also adapt to future growth. With so …

Paint Mate

Discover the Power of the FANUC Paint Mate Robot | Paint Mate by FANUC When it comes to precision and efficiency in painting applications, the FANUC Paint Mate robot truly stands out as a game-changer. Designed specifically for small and medium-sized parts, this versatile robot delivers exceptional performance in a variety of painting tasks. At …

Types of Welding Robots

In the rapidly advancing world of manufacturing, various types of welding robots are becoming indispensable tools for companies. Thus aiming to enhance efficiency, precision, and productivity. These types of welding robots are specifically designed to meet diverse welding needs across industries. Including automotive, aerospace, electronics, and more. As we explore the different types of welding …

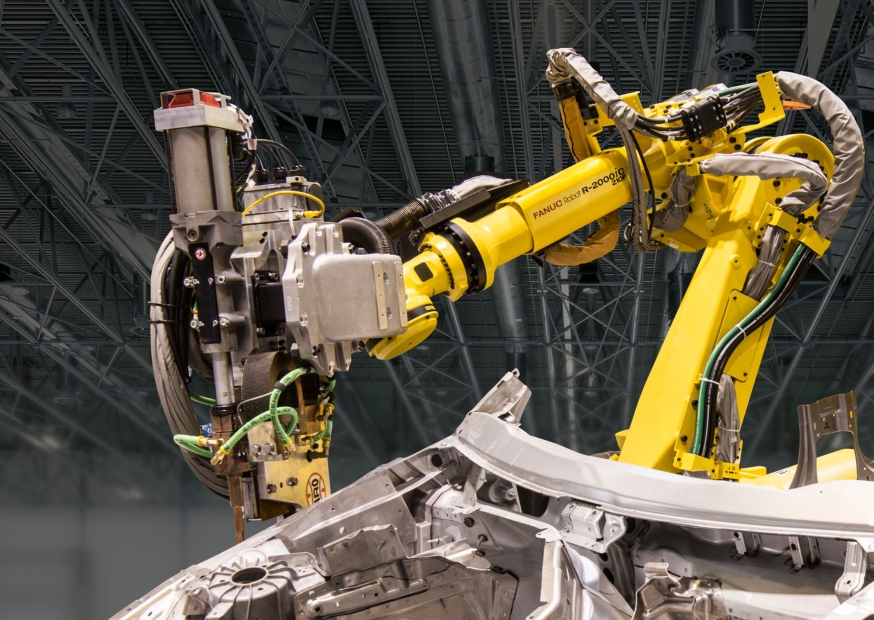

Automotive Robots

In the ever-evolving landscape of the automotive industry, technological advancements have consistently pushed the boundaries of what's possible. Among these advancements, automotive robots have emerged as a critical component, transforming the way vehicles are manufactured. These sophisticated machines, also known as automotive industry robots, are pivotal in enhancing efficiency. Additionally, they enhance precision and overall …

CNC Machine Adelaide

Exploring CNC Machines in Adelaide So, you searched 'CNC Machine Adelaide'... Did you know CNC (Computer Numerical Control) machines are highly automated tools controlled by computers to perform a wide range of manufacturing tasks with exceptional precision? From cutting and shaping materials to drilling and milling, CNC machines streamline production processes and enhance efficiency. Adelaide …

Automated Welding

The Future of Automated Welding In today’s rapidly evolving manufacturing landscape, the integration of advanced technologies is crucial for staying competitive. One such technology that is transforming industries is automated welding. Consequently, it is redefining traditional processes, offering unparalleled precision, efficiency, and productivity. In this article, we will delve into the details of automated welding, …

Robots and Machines

Understanding Robots and Machines Are you unsure about the difference between robots and machines? Many people are unsure about the distinction between these two terms. Let's delve into the specifics of robots and machines, so you’ll be an expert on the topic in no time. Robots and Machines | What is a Machine? To begin …

Industrial Manufacturing

The State of Industrial Manufacturing Within Australia Industrial manufacturing in Australia is a vital component of the nation’s economy. According to the Australian Bureau of Statistics, the manufacturing industry contributed around $100 billion to the country’s GDP in recent years. Moreover, employing over 800,000 people, this sector is crucial for the production of goods that …

Robotics Industry

Exploring the Robotics Industry in Australia and Beyond | Automated Solutions Australia The robotics industry in Australia is experiencing significant growth, driven by advancements in technology and a robust demand for automation across various sectors. With industries such as automotive, aerospace, manufacturing, mining, agriculture, and healthcare increasingly adopting robotic solutions, Australia is positioning itself as …

Robots and Cobots | Cobot Robot

Robots and Cobots | Manufacturing with Collaborative Robots In today's fast-paced industrial landscape, the integration of robots and cobots has become a game-changer. These advanced technologies are transforming manufacturing processes, offering unprecedented efficiency, precision, and safety. At Automated Solutions Australia (ASA), we specialise in integrating FANUC robots and cobots for a variety of applications. Thus …

Robotics Companies

Looking for top-tier robotics companies to partner with? Look no further! Automated Solutions Australia (ASA) are your Australian expert for all things robotic automation. With over 20 years of experience in the industry, we have established ourselves as a leader in integrating cutting-edge FANUC robots. At ASA we believe that FANUC create the gold standard …

Automation Companies Near Me

Automation Companies Near Me | Automation Company Servicing Australia Wide with Expert Integration So, you're searching for top-tier 'automation companies near me?' Look no further! Automated Solutions Australia (ASA) are your go-to partner for your automation needs. While our headquarters are based in Melbourne and Adelaide, our services span across the entire country. Therefore we …

Robotics and Automation Engineering

In today's rapidly evolving industrial landscape, robotics and automation engineering plays a pivotal role in enhancing productivity and efficiency. As one of the leading robotics companies in Australia, Automated Solutions Australia (ASA) stands as an innovative leader in this technological revolution. With over 20 years of experience, ASA has been integrating FANUC robots to streamline …

Robotic Dispensing

Robotic Dispensing | Precision in Manufacturing In the world of modern manufacturing, precision and efficiency are paramount. One way to achieve both of these and more is through the use of robotic dispensing. This innovative process involves the use of robotic systems to accurately apply materials such as adhesives, sealants, and other fluids to specific …

Robotic Mig Welding

MIG Robot Welding | Robotic MIG Welding | MIG Robotic Welding In today's rapidly advancing industrial landscape, robotic systems integration has transformed traditional manufacturing processes. At Automated Solutions Australia, we offer the full range of FANUC welding robots. Specifically, in this article, we will focus on MIG robot welding, which offers unparalleled precision and efficiency. …

Robotic Integration

Robotic integration is transforming industries by enhancing efficiency, precision, and productivity. This guide will walk you through the essentials of robotic integration. This includes its benefits, and how it can transform your business operations. What is Robotic Integration? | Robotic Integration Definition Robotic integration involves incorporating robots into existing manufacturing and production systems to automate …

Robotic Lathe | Robotic Milling

In today's competitive manufacturing landscape, integrating advanced technologies such as robotic lathe and robotic milling systems to keep your lathe and milling CNC machines running around the clock, can significantly enhance productivity, precision, and efficiency. Understanding the capabilities and applications of these robotic solutions can help businesses streamline operations and achieve superior results. Robotic Lathe …

Grit Blasting

Introduction to Grit Blasting | Industrial Surface Treatment Grit blasting, a powerful surface treatment process, is essential in various industries for cleaning, smoothing, and preparing surfaces. This guide will walk you through the fundamentals, its applications, benefits, and how Automated Solutions Australia can revolutionise your operations. What is Grit Blasting? Grit blasting involves propelling abrasive …

Picking and Packaging

Picking and Packaging for Maximum Efficiency in Warehouses Warehouse picking and packaging are crucial processes in fulfilling customer orders. Therefore this process significantly affects the time an order spends in a warehouse. With a large volume of warehouse operating costs attributed to order picking, improving these processes is vital for boosting productivity and overall customer …

Robotics in Business

Robotics in business is transforming the landscape across various sectors, especially with the integration of industrial robots. Therefore the adoption of robotic technologies brings numerous benefits, enhancing productivity, improving quality, and ensuring safety. This article delves into the advantages of using robotics in business and highlights the pivotal role of industrial robots. Benefits of Using …

Laser Welding – Industries & Types

Laser welding is a precise process of fusing metal parts using a beam of laser light. This advanced technique has found numerous applications across various industries, particularly in the automation of small-component welding. It is most useful in the automotive, aerospace, and electronics sectors, where precision and efficiency are critical. This article will further discuss …

Celebrating Two Decades of Excellence: Michael Boonzaayer’s 20-year Journey at ASA

We say it often – our people are our point of differentiation. They are what makes ASA, ASA. And when you’ve had someone who is a part of the vernacular of the company for 20 years, you need to stop and reflect on the enormity of that. We are thrilled to celebrate Michael Boonzaayer, our …

Chernco Engineering: Revolutionising Cowra’s Industrial Landscape through Automation

Nestled in the heart of New South Wales, the picturesque town of Cowra has not only been known for its natural beauty and historical significance but is now emerging as a hub for engineering and manufacturing, all thanks to the remarkable journey of Chernco Engineering. Chernco Engineering has played a pivotal role in transforming Cowra's …

Exciting Announcement – FANUC’s New Paint Cobot

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: More Recent News Stories from ASA: | Robot Welding Cell | Automated …

Meet the Team – Lucas Chrisanthou

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More Recent News Stories from ASA: | Robot Welding Cell | …

Robotic Laser Welding – Applications and Advantages

Robotic Laser Welding: What It Involves Robotic laser welding is a high-precision joining process that uses a focused laser beam, making it ideal for many industries. Specifically, at Automated Solutions Australia (ASA), we integrate FANUC robots for laser welding, ensuring you receive the highest quality and efficiency. How Does Laser Welding Work? Laser welding involves …

Robot Welding Cell

What is a Robot Welding Cell? A robot welding cell is a confined space that houses welding robots. Thus allowing robotic arms to move freely and navigate without the risk of damaging other components or harming operators. Additionally, these cells are equipped with metallic barriers, welding robots, and essential components. In addition, these can include …

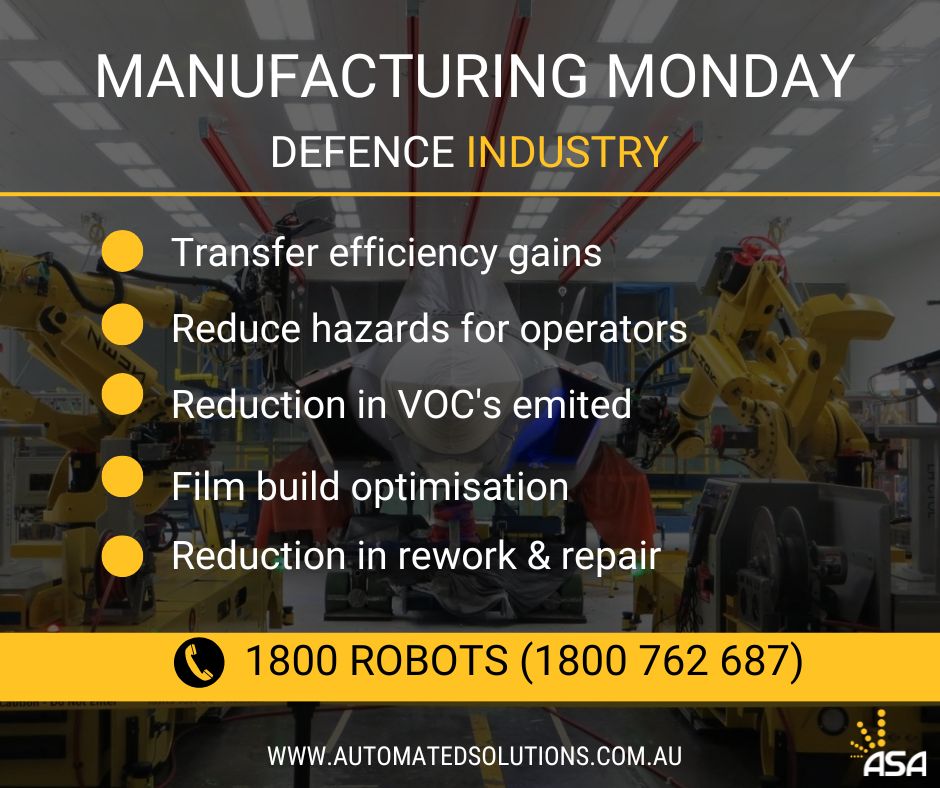

Defence Robot

Defence Robot Integration | The Defence Industry At ASA we are a dedicated team of robotic automation experts, specialising in the design, integration, installation, and ongoing support of robots for many industries, including defence. Moreover, we serve defence primes, original equipment manufacturers (OEMs), and other small and medium-sized enterprises (SMEs), delivering cutting-edge defence robot solutions. …

Automated Picking

Automated Picking | The Advantages In the rapidly evolving landscape of warehouse management and logistics, automated picking systems are dramatically enhancing the efficiency and accuracy of operations. Hence Automated Solutions Australia (ASA) offers FANUC’s state-of-the-art robotic automated picking solutions tailored to the dynamic needs of modern industries. The Need for Speed | Speed and Accuracy …

Advantages of Robotic Welding

Advantages of Robotic Welding - Transforming Industrial Efficiency & Quality In the dynamic landscape of modern manufacturing, the demand for robotic welding solutions is surging. The metal industry alone is witnessing a consistent increase. As companies globally strive to stay competitive, the shift towards robotic systems is becoming an essential strategy. This aids in maintaining …

6 Axis Welding Robot

6 Axis Welding Robot by FANUC At Automated Solutions Australia (ASA), we understand the critical demands of modern manufacturing. So, with over 20 years of expertise in robotic integration, we proudly specialise in FANUC robts. Additionally, we integrate a range of 6-axis welding robots, bringing unparalleled precision and efficiency to industries across the globe. The …

FANUC Robot Programming

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | Choose Another Recent News Story: Advantages of Robotic Welding | Automated Picking | …

Robot Integrator in Australia

Robot Integrator - Automated Solutions Australia (ASA) In the fast-paced realm of industrial manufacturing, the significance of a robot integrator cannot be overstated. Specifically, at Automated Solutions Australia (ASA), we boast over twenty years of experience as a FANUC robot integrator. Consequently, ASA has consistently helped lead the charge in Australia, crafting custom solutions that …

Industrial Applications of Robots

Introduction - Industrial Applications of Robots The landscape of manufacturing and production is being transformed by the industrial applications of robots. Therefore these advanced mechanised tools are pivotal in automating complex processes, enhancing efficiency, and ensuring precision across various sectors. Industrial Applications of Robots in Painting and Dispensing In the realm of painting and coating, …

Robot Welding

The Evolution and Impact of Robot Welding Robot welding has revolutionised the welding process by automating both the welding action and the handling of parts. This innovation is particularly significant in high-production industries like automotive, where it enhances efficiency and safety. Therefore robot welding, distinct from manual operations, allows for consistent, high-speed welding, reducing errors …

Automation Engineering

What is Automation Engineering? | Automation Engineering Definition An Automation Engineer is a skilled professional who designs, develops, and manages automated systems. Thus playing a critical role in advancing factory automation, process automation, and warehouse automation. Automation engineering utilises technology to streamline and automate processes. Therefore enhancing efficiency and reducing the need for human intervention …

Benefits of Robots for Vast Industries

Benefits of Robots in Industries The benefits of robots in the industrial sector is undeniable. According to the International Federation of Robotics, the automotive sector alone employs over one million robots. Thus contributing to a total of around 3 million robots across various industries including electronics, foundry, machinery, plastics, chemicals, healthcare, and food and beverage. …

Materials Handling

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

Robotic Assembly in Australia

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Laminex – A Story of Manufacturing Innovation

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Robotic Welding

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Meet the Team – Sam Nothnagel

Crafting Automation, One Piece at a Time This month, we had the privilege of sitting down with Sam Nothnagel, one of our exceptional employees based out of the Melbourne office at Automated Solutions Australia. Sam's journey into the world of robotic automation has been nothing short of inspiring, and his insights shed light on the …

Welding Automation

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Collaborative Robots

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

What is a PLC?

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Automation in the Manufacturing Industry

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a …

Arc Welding

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

Robotics System – Maximise Efficiency with ASA

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation …

What is a Robotic Cell?

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

CNC Machines Australia

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: | Robotic Arm – An …

What is Cerakote? A Comprehensive Guide to this Innovative Ceramic Coating

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Custom Automation Solutions

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Assembly Robots in Australia

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Why Automate Your Paint Booth with FANUC Robots?

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Ceramic Coating | A Revolutionary Protective Solution for Surfaces

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Automotive Automation Australia

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Pick and Place Robot

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from …

Meet the Team – Franklin Wright

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Understanding Industrial Automation | An Industry Guide

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

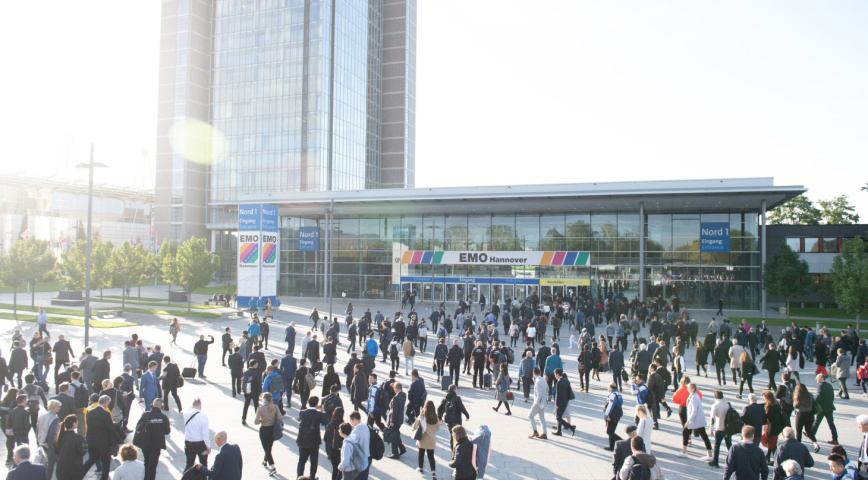

EMO 2023 | Delivering Smart Tech for Tomorrow’s Production

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Customer in Focus | MCHND

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

PLC Automation for Industries

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Deburring Machines

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Human Machine Interface | Plastic Paint Robots | PLC …

A Comparative Analysis of Arc vs. Spot Welding Techniques

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

FANUC Robots in the Energy Sector

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Robotic Automation in the Consumer & Electronics Industry

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Automation in the Heavy Industry

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Automation Technlogy

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Cobot Welding Evolution

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Cobots

Watch a FANUC cobot in action, as it transfers consumer items: Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | …

Robotics Engineering

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation Solutions Australia: Deburring Machines | Robots a Historical Overview | Robotics …

Automatic Paint | Automated Paint

Click an Application to Explore Further: FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening | More (Recent) News Stories from Automation …

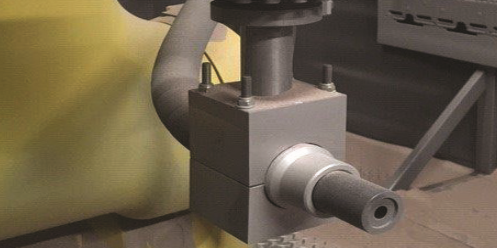

Robotic Loading for CNC Machine Tools